Compaq ProLiant 8500 ProLiant 8500 Server Technology - Page 11

Thermal Design, Katmai New Instructions

|

View all Compaq ProLiant 8500 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 11 highlights

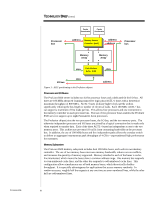

TC000604TB TECHNOLOGY BRIEF (cont.) ... Katmai New Instructions KNI refers to the addition of 70 new instructions to the MMX instruction set. The new instructions primarily refer to the new SIMD-FP registers, but some new integer instructions also have been added. The new instructions are particularly useful for multimedia applications such as 3D rendering and video encoding and decoding. Thermal Design Compaq designed an innovative thermal cooling solution for the Pentium III Xeon processor that contributes to increased system reliability and performance scalability. Heat pipes transfer heat away from the Slot 2 cartridge thermal plate to cooling fins mounted atop the cartridge (Figure 5). Processor Cartridge Heat Fins Heat Pipes Figure 5: Heat pipes and fins for the Pentium III Xeon processor cartridge. This top-mounted position and the direction of the cooling fins are advantageous in two important ways. First, this design cools efficiently regardless of the direction of airflow (vertical or horizontal). Therefore, the ProLiant 8500 server can use the same Slot 2 cartridge and heat sink combination used in other servers, such as the ProLiant 7000 and the ProLiant 8000 servers. Second, because the heat fins are top mounted, the redundant PPM can be placed in its optimal position, next to the processor, to maintain short signal trace lengths across the 100-MHz system bus. The resulting improvements to power supply regulation and system bus signal quality increase system reliability. To further reduce any cooling issues that may arise from packing so much power into such a small form factor, Compaq also improved the design of the ProLiant 8500 chassis. As show in Figure 6, a spring-loaded trap door has been added to each power supply bay. When a power supply is removed, the trap door will close to block the opening. This door preserves the air path required to cool the internal components of the server. It also allows the server to maintain availability with only one power supply and gives the administrator more time to replace the power supply. Spring-loaded trap doors Figure 6: Spring-loaded trap doors in the power supply bays of the ProLiant 8500 server. 11