Dell PowerVault 122T SDLT 320 Dell PowerVault DLT, VS, and SDLT Media Handbook - Page 14

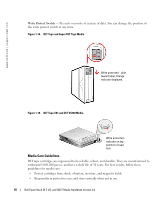

Cartridge, Cartridge Door, Write Protect Switch, Cartridge Leader, DLTtape Cartridges

|

View all Dell PowerVault 122T SDLT 320 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 14 highlights

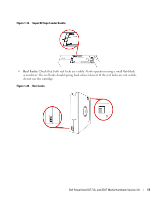

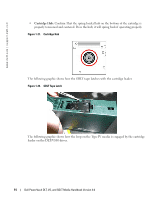

www.dell.com | support.dell.com Cartridge Inspection • Case: Inspect the case for cracks, chips, or signs of damage. • Cartridge: Inspect the exterior of the cartridge for chips, cracks, dents, or missing screws. Gently shake the cartridge. Listen for rattling or loose pieces. • Cartridge Door: Ensure that the door is moveable and that the spring is present. • Write Protect Switch: Move the switch. It should snap into write-protected mode and write- enabled mode. • Cartridge Leader: Gently inspect the cartridge leader to verify that it has not been damaged and is in the correct position. • DLTtape Cartridges: Check the height of the leader to ensure that the loop is sticking up approximately 3/16 inch or 4 mm. Ensure that the door operates. DLT tape leader loop should be visible and undamaged. • Super DLTtape Cartridges: Check that the Super DLTtape leader buckle aligns with cartridge edge and metal pin is not bent. NOTE: When inspecting the cartridge leader do not use anything that could leave contamination, such as a pen or pencil. Figure 1-18. DLTtape Leader Loop 12 Dell PowerVault DLT, VS, and SDLT Media Handbook Version 2.0