HP Scitex LX850 HP Scitex LX850 & LX820 Printers: Site Preparation Checkli - Page 5

LX800, 200-220V, 380-415V

|

View all HP Scitex LX850 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 5 highlights

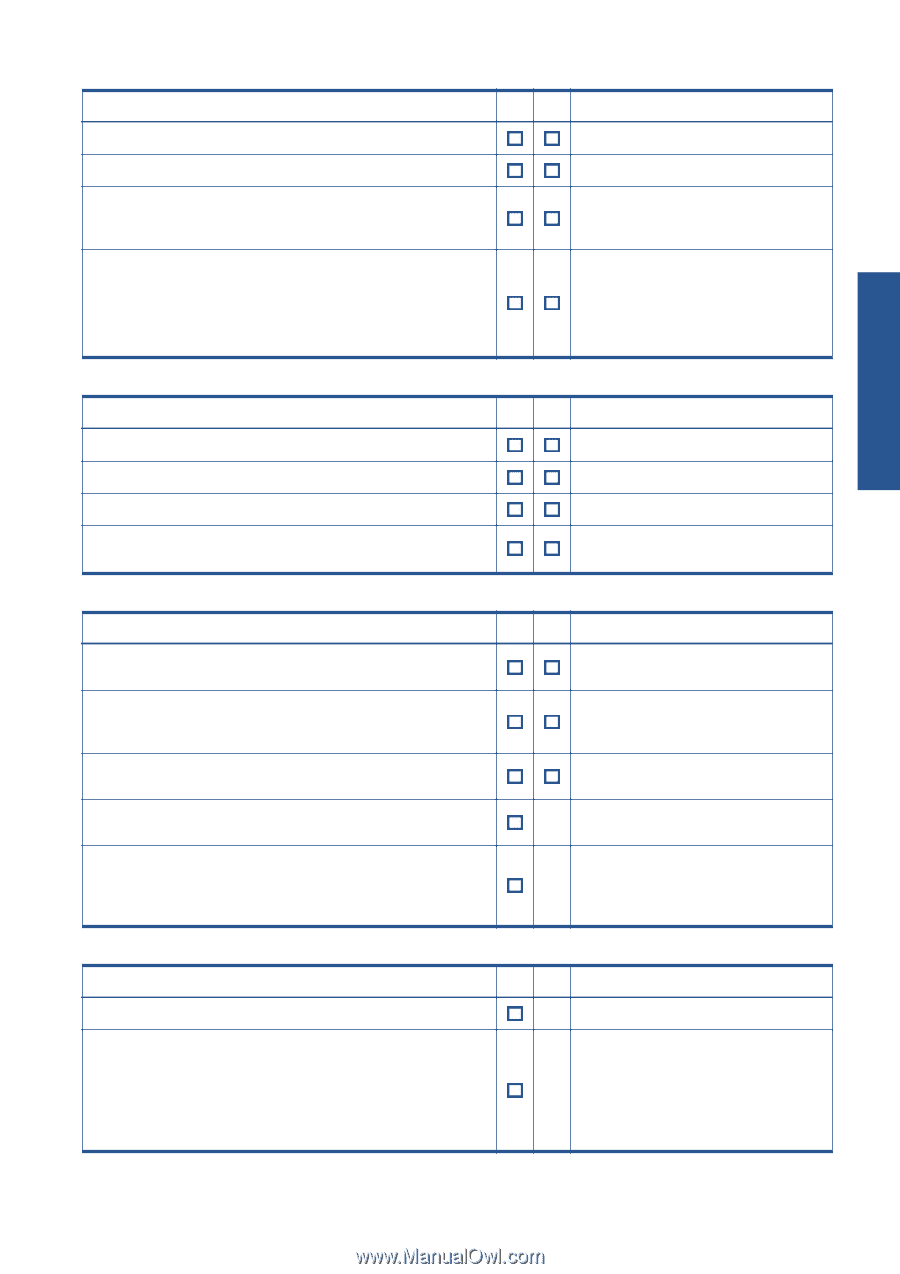

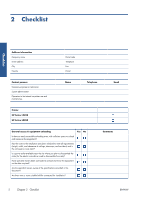

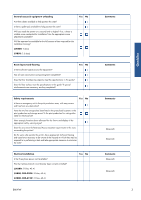

General access & equipment unloading Are there skates available to help position the crate? Is there a pallet jack available to help position the crate? Will you install the printer on a second level or higher? If so, is there a suitable crane contracted for installation? Are the appropriate crane attachments available? Will the operator be available for the full amount of time required for the installation training? ((LX820: 2 days) (LX850: 2.5 days) Yes No Room layout and flooring Is there sufficient space around the equipment? Has all room construction and painting been completed? Does the floor load-bearing capacity meet the specifications in this guide? Does the floor surface meet the specifications in this guide? If special reinforcements are necessary, are they completed? Yes No Safety requirements Yes No Is there an emergency exit in the print production area, with easy access and free from any obstruction? Have the two fire extinguishers been fitted in the prescribed locations in the print production and storage areas? Is the print production fire extinguisher rated for electrical fire? Have strategic locations been allocated for the fixture and display of the appropriate safety warning signs? Does the area meet the Restricted Access Location requirements in the zone surrounding the printer? Do the users who operate the printer, have appropriate technical training and experience necessary to be aware of the hazards to which they may be exposed to in performing a task and take appropriate measures to minimize the risks? Electrical installation Is the three phase power cord available? Has the tri-phase branch circuit breaker been correctly installed? ((LX600: 3 Poles, 40 A) (LX800, 200-220V: 3 Poles, 63 A) (LX800, 380-415V: 3 Poles, 40 A) Yes No ENWW Comments Comments Comments (Required) (Required) Comments (Required) (Required) 3 Checklist