Hitachi NT50GS Instruction Manual - Page 33

screwdriver

|

UPC - 717709014428

View all Hitachi NT50GS manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 33 highlights

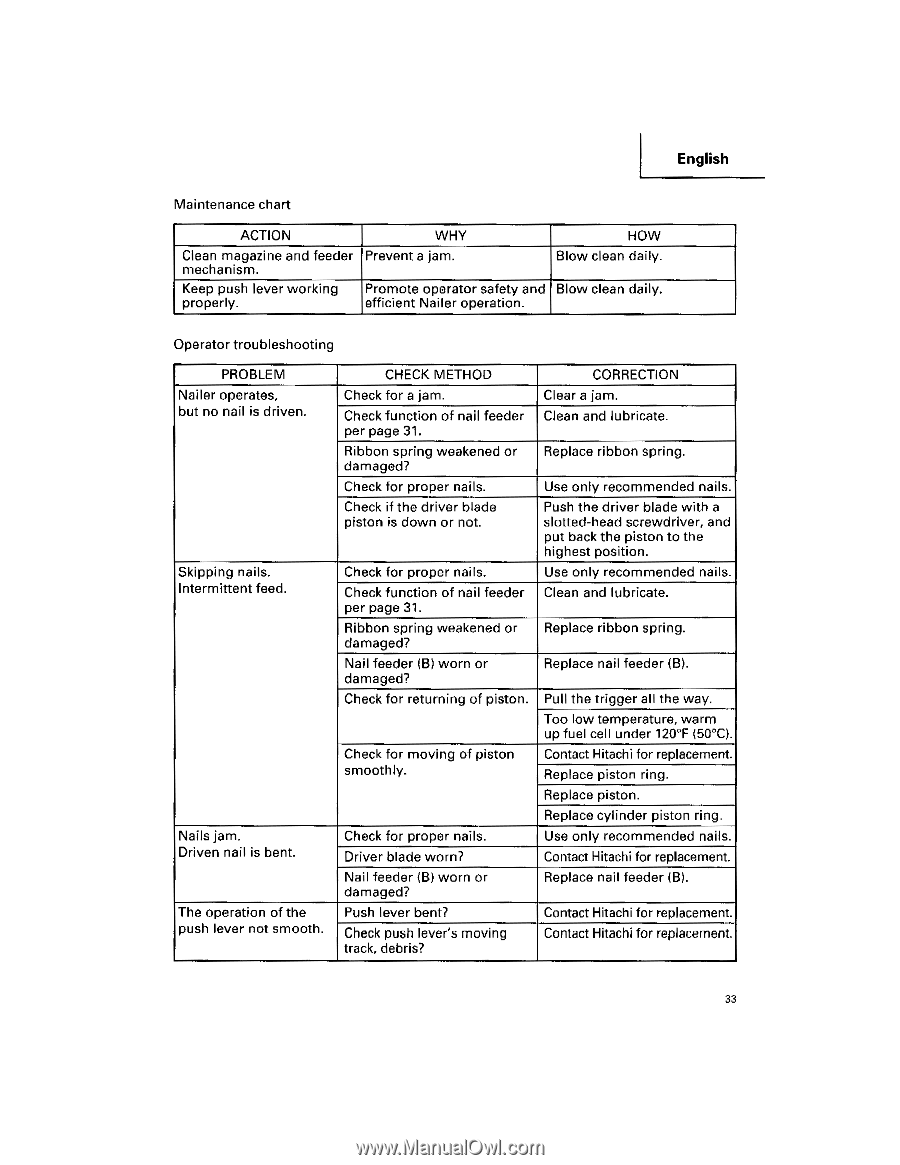

English Maintenance chart ACTION WHY HOW Clean magazine and feeder Prevent a jam. mechanism. Blow clean daily. Keep push lever working Promote operator safety and Blow clean daily. properly. efficient Nailer operation. Operator troubleshooting PROBLEM Nailer operates, but no nail is driven. Skipping nails. Intermittent feed. Nails jam. Driven nail is bent. The operation of the push lever not smooth. CHECK METHOD Check for a jam. Check function of nail feeder per page 31. Ribbon spring weakened or damaged? Check for proper nails. Check if the driver blade piston is down or not. Check for proper nails. Check function of nail feeder per page 31. Ribbon spring weakened or damaged? Nail feeder (B) worn or damaged? Check for returning of piston. Check for moving of piston smoothly. Check for proper nails. Driver blade worn? Nail feeder (B) worn or damaged? Push lever bent? Check push lever's moving track, debris? CORRECTION Clear a jam. Clean and lubricate. Replace ribbon spring. Use only recommended nails. Push the driver blade with a slotted-head screwdriver, and put back the piston to the highest position. Use only recommended nails. Clean and lubricate. Replace ribbon spring. Replace nail feeder (B). Pull the trigger all the way. Too low temperature, warm up fuel cell under 120°F (50°C). Contact Hitachi for replacement. Replace piston ring. Replace piston. Replace cylinder piston ring. Use only recommended nails. Contact Hitachi for replacement. Replace nail feeder (B). Contact Hitachi for replacement. Contact Hitachi for replacement. 33