Husqvarna PW3300 Operation Manual - Page 22

Specifications, Maintenance Schedule, Maintenance, Clean Debris - lowes

|

View all Husqvarna PW3300 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 22 highlights

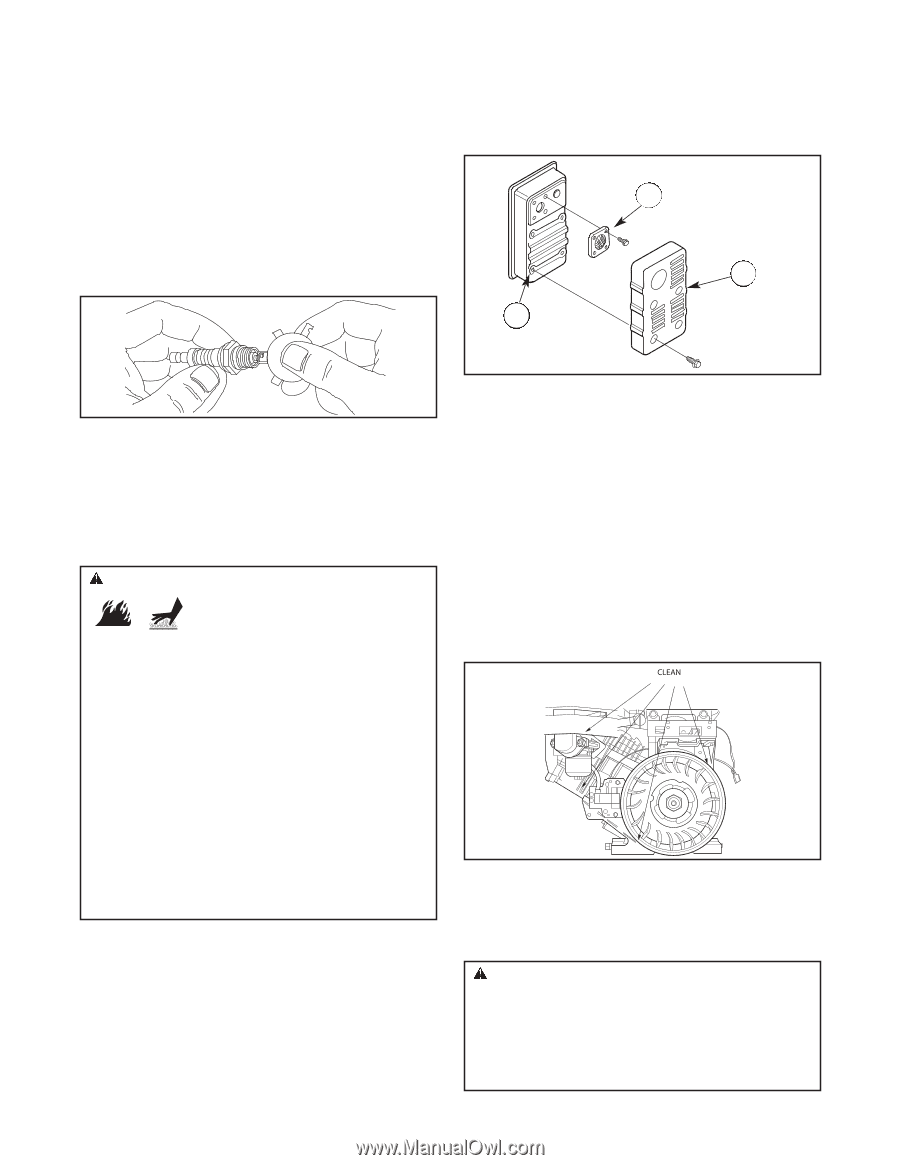

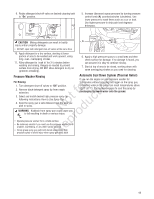

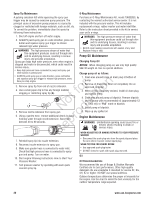

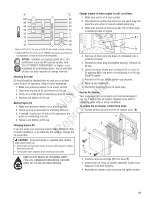

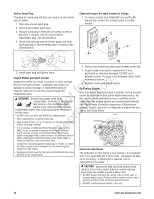

Service Spark Plug Changing the spark plug will help your engine to start easier and run better. 1. Clean area around spark plug. 2. Remove and inspect spark plug. 3. Replace spark plug if electrodes are pitted, burned or porcelain is cracked. Use the recommended replacement plug. See Specifications. 4. Check electrode gap with wire feeler gauge and reset spark plug gap to recommended gap if necessary (see Specifications). Clean and inspect the spark arrester as follows: 1. To remove muffler heat shield (A) from muffler (B), remove four screws that connect guard to muffler bracket. C A B 2. Remove four screws that attach spark arrester screen (C). 5. Install spark plug and tighten firmly. 3. Inspect screen and obtain a replacement if torn, perforated or otherwise damaged. DO NOT use a Inspect Muffler and Spark Arrester Inspect the muffler for cracks, corrosion, or other damage. r n Remove the spark arrester, if equipped, and inspect for damage or carbon blockage. If replacement parts are fo tio required, make sure to use only original equipment replacement parts. t WARNING Exhaust heat/gases could ignite c combustibles, structures or damage fuel o u tank causing a fire, resulting in death, serious injury and/or property damage. N d Contact with muffler area could cause burns resulting in serious injury. o • DO NOT touch hot parts and AVOID hot exhaust gases. r • Allow equipment to cool before touching. • Keep at least 5 feet (1.5 m) of clearance on all sides of pressure p washer including overhead. e • It is a violation of California Public Resource Code, Section 4442, to use or operate the engine on any forest-covered, R brush-covered, or grass-covered land unless the exhaust defective screen. If screen is not damaged, clean it with commercial solvent. 4. Reattach screen and muffler guard. Air Cooling System Over time debris may accumulate in cylinder cooling fins and cannot be observed without partial engine disassembly. For this reason, we recommend you have a qualified service dealer clean the cooling system per recommended intervals (see Maintenance Schedule in beginning of Maintenance section). Equally important is to keep top of engine free from debris. See Clean Debris. system is equipped with a spark arrester, as defined in Section 4442, maintained in effective working order. Other states or federal jurisdictions may have similar laws. Contact the original equipment manufacturer, retailer, or dealer to obtain a spark arrester designed for the exhaust system installed on this engine. Carburetor Adjustment • Replacement parts must be the same and installed in the same position as the original parts. The carburetor on this engine is low emission. It is equipped with a non-adjustable idle mixture valve. Top speed has been set at the factory. If adjustment is required, see an authorized service dealer. CAUTION Excessively high operating speeds could result in minor injury and/or pressure washer damage. Excessively low speeds impose a heavy load. • DO NOT tamper with governor spring, links or other parts to increase engine speed. Pressure washer supplies correct rated pressure and flow when running at governed speed. • DO NOT modify pressure washer in any way. 22 www.usa.husqvarna.com