LG WKGX201HWA Owners Manual - Page 21

Connecting the Gas Supply

|

View all LG WKGX201HWA manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 21 highlights

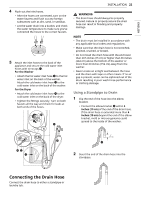

• Supply line requirements: Your laundry room must have a rigid gas supply line to your dryer. In the United States, an individual manual shutoff valve MUST be installed within at least 6 ft. (1.8 m) of the dryer, in accordance with the National Fuel Gas Code ANSI Z223.1 or Canadian gas installation code CSA B149.1. A 1/8-inch NPT pipe plug must be installed. • If using a rigid pipe, the rigid pipe should be 0.5inch IPS. If acceptable under local codes and ordinances and when acceptable to your gas supplier, 3/8-inch approved tubing may be used where lengths are less than 20 ft. (6.1 m). Larger tubing should be used for lengths in excess of 20 ft. (6.1 m). • To prevent contamination of the gas valve, purge the gas supply of air and sediment before connecting the gas supply to the dryer. Before tightening the connection between the gas supply and the dryer, purge remaining air until the odor of gas is detected. • Use only a new AGA- or CSA-certified gas supply line (in compliance with the Standard for Connectors for Gas Appliances, ANSI Z21.24 • CSA 6.10) with flexible stainless steel connectors. • Use Teflon tape or a pipe-joint compound that is insoluble in propane (LP) gas on all pipe threads. Connecting the Gas Supply NOTE • In the Commonwealth of Massachusetts: This product must be installed by a licensed plumber or gas fitter. When using ball-type gas shut off valves, they must be T-handle-type. A flexible gas connector, when used, must not exceed 3 feet. • Installation and service must be performed by a qualified installer, service agency, or the gas supplier. • The dryer is configured for natural gas when shipped from the factory. Make sure that the dryer is equipped with the correct burner nozzle for the type of gas being used (natural gas or propane gas). • Use only a new stainless steel flexible connector and a new AGA-certified connector. • A gas shutoff valve must be installed within 6 ft. (1.8 m) of the dryer. • If necessary, the correct nozzle (for the LP nozzle kit, order part number 383EEL3002D) should be installed by a qualified technician and the change should be noted on the dryer. INSTALLATION 21 • All connections must be in accordance with local codes and regulations. Gas dryers MUST exhaust to the outdoors. 1 Make sure that the gas supply to the laundry room is turned OFF and the dryer is unplugged. Confirm that the type of gas available in your laundry room is appropriate for the dryer. 2 Remove the shipping cap from the gas fitting at the back of the dryer. Be careful not to damage the threads of the gas connector when removing the shipping cap. 3 Connect the dryer to your laundry room's gas supply using a new flexible stainless steel connector with a 3/8-inch NPT fitting. WARNING • DO NOT use old connectors. 4 Securely tighten all connections between the dryer and your laundry room's gas supply. 5 Turn on your laundry room's gas supply. 6 Check all pipe connections (both internal and external) for gas leaks with a noncorrosive leak-detection fluid. 7 Proceed to Venting the Dryer. a 3/8'' NPT Gas Connection b AGA/CSA-Certified Stainless Steel Flexible Connector c 1/8" NPT Pipe Plug d Gas Supply Shutoff Valve ENGLISH