Lexmark C912 Service Manual

Lexmark C912 Manual

|

View all Lexmark C912 manuals

Add to My Manuals

Save this manual to your list of manuals |

Lexmark C912 manual content summary:

- Lexmark C912 | Service Manual - Page 1

Revised October 17, 2006 Lexmark C91x 5055-xxx • Table of Contents • Start Diagnostics • Safety and Notices • Trademarks • Index Lexmark and Lexmark with diamond design are trademarks of Lexmark International, Inc., registered in the United States and/or other countries. - Lexmark C912 | Service Manual - Page 2

inaccuracies or typographical errors. Changes are periodically PostScript® is a registered trademark of Adobe Systems Incorporated. Other trademarks are the property of their respective owners. © 2003, 2004 Lexmark International, Inc. All rights reserved. UNITED STATES GOVERNMENT RIGHTS This software - Lexmark C912 | Service Manual - Page 3

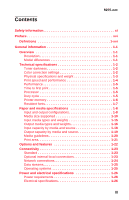

differences 1-1 Technical specifications 1-2 Toner darkness 1-2 Color correction settings 1-2 Physical specifications and weight 1-3 Print speed and performance 1-4 Performance 1-5 Time to first print 1-5 Processor 1-5 Duty cycle 1-5 Printer memory 1-6 Resident fonts 1-7 Paper and media - Lexmark C912 | Service Manual - Page 4

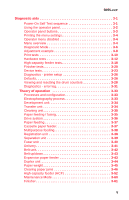

check 2-82 Paper skew service check 2-83 Paper tray missing service check 2-83 Photodeveloper missing service check 2-84 Power supply service check 2-85 210 Staple jam service check 2-86 Transfer belt up/down service check 2-87 Image quality troubleshooting 2-88 Print quality problems 2-88 - Lexmark C912 | Service Manual - Page 5

system 3-36 Paper feeding 3-37 Cassette paper feeder 3-37 Multipurpose feeding 3-38 Registration unit 3-38 Separation unit 3-39 Fuser unit 3-40 Delivery 3-41 Belt unit 3-42 Belt up/down 3-43 Expansion paper feeder 3-43 Duplex unit 3-44 Paper weight 3-45 Clearing paper jams 3-46 High - Lexmark C912 | Service Manual - Page 6

Cover, RIP board removal 4-9 Tray, paper exit removal 4-10 Belt up/down clutch removal 4-10 Belt up/down detection sensor removal 4-11 Cassette guide removal 4-12 Connector, duplex unit removal 4-13 Separation fingers removal 4-14 Sensor cleaner removal 4-14 Drive gear unit sensor assembly - Lexmark C912 | Service Manual - Page 7

4-55 Transfer belt removal 4-56 Turn guide cover sensor removal 4-65 Upper fan removal 4-66 Options removals 4-67 Expansion paper feeder removal 4-67 Duplex removals 4-75 Duplex unit separation removal 4-75 Duplex unit removal 4-76 Duplex timing belt removal 4-76 Duplex pressure roller and - Lexmark C912 | Service Manual - Page 8

power supply board 5-15 Sensor board 5-15 Expansion paper feeder controller board 5-16 Duplex unit controller board 5-16 Motor drive board 5-16 Size sensor board 5-17 High-capacity feeder (HCF 5-18 High-capacity paper feed configuration 5-18 Electrical parts layout 5-19 viii Service Manual - Lexmark C912 | Service Manual - Page 9

9: Base 3 7-20 Assembly 10: Electrical 7-22 Assembly 11: Rip board 7-26 Assembly 12: Fuser unit 7-28 Assembly 13: Cassette 7-30 Assembly 14: Expansion feeder 1 7-32 Assembly 15: Expansion feeder 2 7-34 Assembly 16: Duplex unit 1 7-38 Assembly 17: Duplex unit 2 7-40 Assembly 18: High - Lexmark C912 | Service Manual - Page 10

5055-xxx P/N 56P9480 7-81 Index I-1 Part number index I-9 x Service Manual - Lexmark C912 | Service Manual - Page 11

and approvals of the original design and specific components. The manufacturer is not responsible for safety in the event of use of unauthorized replacement parts. • The maintenance information for this product has been prepared for use by a professional service person and is not intended to - Lexmark C912 | Service Manual - Page 12

le precauzioni necessarie. • ATTENZIONE: Questo simbolo indica la presenza di tensione pericolosa nell'area del prodotto. Scollegare il prodotto prima di iniziare o usare cautela se il prodotto Produkt für die Ausführung der Arbeiten an den Strom angeschlossen sein muß. xii Service Manual - Lexmark C912 | Service Manual - Page 13

personal cualificado debe ser consciente de este peligro y tomar las precauciones necesarias. • PRECAUCIÓN: este símbolo indica que el voltaje de la parte del equipo con la que está trabajando es peligroso. Antes de empezar, desenchufe el equipo o tenga cuidado si, para trabajar con él, debe - Lexmark C912 | Service Manual - Page 14

producte. El personal professional ha d'estar-ne assabentat i prendre les mesures convenients. • PRECAUCIÓ: aquest símbol indica que el voltatge de la part de l'equip amb la qual esteu treballant és perillós. Abans de començar, desendolleu l'equip o extremeu les precaucions si, per treballar - Lexmark C912 | Service Manual - Page 15

5055-xxx Safety information xv - Lexmark C912 | Service Manual - Page 16

contains an error indicator table, symptom tables, and service checks used to isolate failing field replaceable units (FRUs). 3. Diagnostic aids contains tests and checks used to locate or repeat symptoms of printer problems. 4. Repair information provides instructions for making printer adjustments - Lexmark C912 | Service Manual - Page 17

5055-xxx Overview The Lexmark™ C91x printers are high-speed, wide-format color LED Electrophotographic color printers with superior print quality for high-volume printing. Resolution • 600 x 600 dpi • 2400 image quality Model differences 5055-230 C912 5055-210 C912 5055-200 C912 5055-01N C910 5055 - Lexmark C912 | Service Manual - Page 18

's color correction instead of the printer's algorithms Black and White Lock-(in configuration menu) allows printer and network administrators to lock the printer in a mode that will only print black. This feature cannot be overridden with any other menu or driver selection. 1-2 Service Manual - Lexmark C912 | Service Manual - Page 19

drawer. 3 Finisher model is a duplex model printer with 1100-sheet punch finisher and printer cabinet. 4 Fully configured models include base printer with four standard 550-sheet input trays, 3000-sheet feeder, 1100-sheet staple punch finisher, duplex unit, and printer base. General information 1-3 - Lexmark C912 | Service Manual - Page 20

N/A N/A 11 Paper labels 22 N/A 22 Duplex printing on letter-size media (sides per minute)1,2,3,4 Letter-8.5 in. x 11 in. 19 19 19 Ledger 11 N/A 11 Legal-8.5 in. x 14 in. 12 N/A 12 A3 11 N/A 11 A4-3.4 in. x 11.7 in. 19 19 19 A5/Executive N/A N/A 20 1-4 Service Manual - Lexmark C912 | Service Manual - Page 21

paper path to achieve the maximum duplex print performance. Performance The Lexmark C91x printers support the speeds listed above. Performance depends on: • Interface to the host (USB, serial, parallel, network) • Host system and application • Page complexity and content • Certain printer options - Lexmark C912 | Service Manual - Page 22

and expansion slots • Memory slots for extra flash or DRAM - Two for Lexmark C910(n) and Lexmark C912(n) - One for Lexmark C910(dn) and Lexmark C912(dn) • One expansion slot for optional interface cards • One optional firmware expansion slots (application solution firmware card) • One on-board hard - Lexmark C912 | Service Manual - Page 23

all seven Windows symbol sets. Additional fonts can be downloaded to the printer RAM, optional Flash DIMM or hard disk. PCL emulation supports both scalable and bitmapped downloadable fonts. PostScript emulation supports only downloadable scalable fonts. Font cards and font cartridges are not - Lexmark C912 | Service Manual - Page 24

is subject to media specifications and printer operating environment. Capacities listed are based on plain paper at 75 g/m2. Input and output configurations Sources and capacities Lexmark C91x Input sources Number of standard sources Optional input drawers High-capacity feeder Maximum number of - Lexmark C912 | Service Manual - Page 25

1 1 1 Output capacities sheets Standard output bin 550 550 550 Face-up bin 100 100 100 Optional Finisher3,4 1,000 1,000 1,000 Maximum output capacity 1,650 1,650 1,650 Other Duplex unit Yes Yes Standard 1 The heavy media tray is supported only as Tray 1 (top). 2 A maximum of - Lexmark C912 | Service Manual - Page 26

xxx Media size supported Input 500-sheet input multipurpose feeder High-capacity feeder Duplex Heavy media tray A4-8.27" x 11.7 in. (210 mm x 297 mm) X X X X X A5-5.83" x 8.27 in. (148 mm x 210 mm X X X JIS-B5-7.17 in.x 10.23 in. (182 mm x 257mm) X X JIS-B4-4.34 in. x 10.1 in. (364 mm - Lexmark C912 | Service Manual - Page 27

5055-xxx 500-sheet input multipurpose feeder High-capacity feeder Duplex Heavy media tray Universal1,2 Banner 11.69 x 36 in. (297.2 x 914.4 mm) Lexmark C912 only 2.75 x 5 in. to 8.5 x 14 in. (69.85 x 127 mm to 229 x 355.6 mm) 5.83 x 7.17 in. to 8.5 x 14 in. (148 x 182 mm to 215.9 x 355.6 mm) 7 ¾ - Lexmark C912 | Service Manual - Page 28

-xxx 500-sheet input multipurpose feeder High-capacity feeder Duplex Heavy media tray Media type Paper Card stock Transparencies Envelopes Glossy paper Paper labels Output X X X X X5 X X X6 X7 X X X X X X8 Standard output Bin 1 Finisher Bin 1 Finisher Bin 2 A4-8.27 in. x 11.7 in - Lexmark C912 | Service Manual - Page 29

5055-xxx Standard output Bin 1 Finisher Bin 1 Finisher Bin 2 Legal-8.5 in. x 14 in. (216 mm x 256 mm) X X X Executive-7.25 in. x 10.5 in. (184 mm x 267 mm) X X X Tabloid-11 in. x 17 in. (279.4 mm x 431.8 mm) X X X 12 in. x 18 in. (305 mm x 457 mm) Lexmark C912 only X X X A3-11.69 - Lexmark C912 | Service Manual - Page 30

.9 x 355.6 mm) unless the size is specified in the software application. 2 Narrow media should be loaded with the length in the feed direction (portrait). 3 A5 paper 5.83 x 8.27 in. (148 x 210 mm) is the smallest size the printer can duplex. 4 When Other Envelope is selected, the page is formatted - Lexmark C912 | Service Manual - Page 31

5055-xxx Media Weight Standard trays1, 2, 3 Paper-xerographic or business Specialty papers-glossy laser Heavy media tray1 16 to 28 lb bond (60 to 105 g/m2) 80 lb book (32 lb bond) (120 g/m2) Paper-xerographic or business Specialty papers-glossy laser4 Transparencies-laser printer type5 Labels - Lexmark C912 | Service Manual - Page 32

-xxx Output media types and weights Media Standard output3 Paper-xerographic or business Specialty papers-glossy laser Card stock-upper limit Index Bristol Transparencies-laser printer type Labels-upper limit paper Bin 13, 4 Paper-xerographic or business Specialty papers-glossy laser1 Card stock - Lexmark C912 | Service Manual - Page 33

5055-xxx Media Weight Finisher bin 23, 4, 5 Paper-xerographic or business 16 to 28 lb bond (60 to 105 g/m2) 1 Part numbers 12A5950 (letter) and 12A5951 (A4). 2 Part numbers 12A5940 (letter) and 12A5941 (A4). 3 The duplex option supports the same weights and types as the printer, except for - Lexmark C912 | Service Manual - Page 34

trays Plain paper (letter, A4, legal, tabloid, A3) Plain paper (letter, A4, legal, tabloid, A3) Glossy paper Multipurpose feeder Plain paper Transparencies Envelopes Card stock Paper labels Glossy paper High-capacity feeder Plain paper Heavy media tray Plain paper Transparencies Paper Service Manual - Lexmark C912 | Service Manual - Page 35

(175 g/m2) 1,000 sheets 20 lb (75 g/m2) • Performance may vary subject to media specifications and printer operating environment • Media at ambient environment • All media is letter/A4, unless otherwise noted • All paper weights are stated in bond, unless otherwise noted General information 1-19 - Lexmark C912 | Service Manual - Page 36

dimension may be used. To print smaller envelopes, the finisher must be undocked during the job. • If envelope wrinkling occurs, refer to the User's Guide for correct weight, type, loading and stacking of envelopes. • All envelopes should be new, unused and without package damage. • Envelopes with - Lexmark C912 | Service Manual - Page 37

in the User's Guide or the Cardstock and Label Guide, and tested for acceptability. Lexmark glossy paper • Use letter (p/n 12A5950) or A4 (p/n 12A5951) only • Glossy paper is only supported from Tray 1, Multipurpose Feeder, and Heavy Media Tray. Print area Printable area for the printer is to within - Lexmark C912 | Service Manual - Page 38

, labels and glossy paper. This is supported only as Tray 1 (top drawer location). • Duplex unit-offers two-side printing and is designed to complement the Lexmark C91x printers. • Finisher-offers stapling, hole punching, offset stacking and an additional output bin. Two models are available - Lexmark C912 | Service Manual - Page 39

Connectivity Standard • Lexmark C91x - Bidirectional parallel and USB • Lexmark C91xn and Lexmark C91xdn - 10/100BaseTX Ethernet and USB Note: USB is supported only under Windows 98 SE, Windows Me, Windows XP, Windows 2000 operating systems, Sun's Sun Ray appliances running Sun Ray Server code - Lexmark C912 | Service Manual - Page 40

external print servers support NetPnP 7.0 or later on Windows NT 4.0, Windows 2000 and Windows XP systems. The Ethernet and Token-Ring print servers and the standard Ethernet connection support the following protocols: • TCP/IP • Novell (IPX/SPX including NetWare Directory Services) • AppleTalk - Lexmark C912 | Service Manual - Page 41

MIB), http, lpr/lpd, ftp, tftp, ping, finger, telnet, bootp and rarp. The following protocols are also supported: • IPP: Internet Printing Protocol • SLP: Service Location Protocol • NTP: Network Timing Protocol Printers with standard Ethernet, MarkNet N2000 series and MarkNet N2003 series internal - Lexmark C912 | Service Manual - Page 42

mono Continuous color 400 W 290 W Average power while printing Continuous mono Continuous color 13 W 125 W Average power while printing Continuous mono Continuous color 11 A 6 A * 0 W. Always active and drawing voltage. Network * 400 W 290 W 14 W 125 W 11 A 6 A Duplex/ network * 410 W 300 - Lexmark C912 | Service Manual - Page 43

the right side should be 13 in. (330 mm) with the duplex attached, but not the high-capacity feeder. With the high-capacity feeder or finisher attached, the top clearance needs to be 43.8 in. (1,113 mm). Environment Printer temperature and humidity Operating • Temperature: 60 to 90° F (15.6 to 32 - Lexmark C912 | Service Manual - Page 44

: 85° F (30° C) • Altitude: 34,000 ft. (10,300 meters) Storing printer without print cartridges • Temperature: 0 to 140° F (0.6 to 60° C) • some cases, performance specifications (such as paper OCF or EP cartridge usage) are specified to be measured at an ambient condition. 1-28 Service Manual - Lexmark C912 | Service Manual - Page 45

you to the correct field replaceable unit (FRU) or part. Use the error code charts, symptom index, and service checks to determine the symptom and repair the failure. The removals in the repair information chapter may help you identify parts. • "Printer messages" on page 2-4 • "Symptom table" on - Lexmark C912 | Service Manual - Page 46

/toner cartridges, belts, fuser CRUs) and paper sources (cassettes, trays, feeders, duplex drawers, finishers, mailbox trays) for obvious damage and proper installation (paper under corner bucklers, paper guides not too tight). Inspect for correct media usage (paper, transparencies, labels). • Print - Lexmark C912 | Service Manual - Page 47

5055-xxx Tools The removal and adjustment procedures require the following tools and equipment: • Magnetic tip Phillips screwdrivers, large and small • Flat-blade screwdrivers • Analog volt ohmmeter (a digital volt ohmmeter may also be used) • Needle nose pliers • Tweezers, C-ring pliers • Magnifier - Lexmark C912 | Service Manual - Page 48

5055-xxx Serial number, configuration ID, and part number Open the front door. The serial number, configuration ID, and part number are located as shown. The serial number is also on the menu settings page you can print from the Tests Menu. Serial Number Config ID P/N 1-32 Service Manual - Lexmark C912 | Service Manual - Page 49

POST PQET RIP ROS SRAM UPR V ac V dc Application-specific integrated circuit Customer setup Dynamic random access memory Electrophotographic process Erasable programmable read-only memory Electrostatic discharge Field replaceable unit High voltage power supply Local area network Light amplification - Lexmark C912 | Service Manual - Page 50

5055-xxx 1-34 Service Manual - Lexmark C912 | Service Manual - Page 51

while you are working on the printer, go to the error message table and take the indicated action. Adjustments and procedures following parts replacement Note: When troubleshooting, or prior to making any adjustment to print quality, always be sure: • The printer is installed on a level rigid - Lexmark C912 | Service Manual - Page 52

replacing the RIP controller board, it is necessary to type in the following items in Diagnostic Mode: • Set Serial Number • Configuration ID Transfer belt If you replace the transfer belt, check the printer alignment (X, Y, and Theta), adjusted in diagnostic mode. LED printhead controller board - Lexmark C912 | Service Manual - Page 53

troubleshooting, check the following: Installation environment • The power supply line voltage is plus or minus 10% of the rated line areas. • Avoid sites exposed to direct sunlight. Print paper checks • Use the recommended paper for this printer. • Paper dampness. Make a trial print with paper - Lexmark C912 | Service Manual - Page 54

, requiring no action. Attendance messages alert the operator to printer problems that require operator intervention. Service error message tables 900 - Unrecoverable Software Error 910 Service Motor Error 910 - Drive Motor Error Step Questions/actions Yes No 1 Are connectors CN1 and Go to - Lexmark C912 | Service Manual - Page 55

the paper exit motor solve the printer controller problem? board. 912 - High-Capacity Feed Motor Error Step Questions/actions Yes No 1 Is connector CN40 on the printer controller board securely connected? 917 - RIP Fan Error 917 Service Fan Error Go to "Highcapacity feeder (HCF) service - Lexmark C912 | Service Manual - Page 56

power supply CN6 on the printer fan. controller board? No Replace the printer controller board. 92x Service Fuser Error 920 - Fuser Error-Fuser Heater Trouble Step Questions/actions Yes No 1 Replace the fuser. Did this Problem solved. Return the fuser, fix the problem? replace the power - Lexmark C912 | Service Manual - Page 57

short pins 1 and 4 of CN44 fuser. and power on. Is error 923 displayed? Replace the printer controller board. 924 - Lower Fuser Thermistor Open Error Step Questions/actions Yes No 1 Turn off the printer and Problem solved Go to step 2 reinstall the fuser, making sure it clicks into place - Lexmark C912 | Service Manual - Page 58

925 - HVU Error Step Questions/actions printer controller board printer controller connector in connected properly? board. securely. Go to step 3. 3 Did replacing the printer controller board fix the problem? Problem solved. Replace the high voltage power board (HVU). 2-8 Service Manual - Lexmark C912 | Service Manual - Page 59

encoder wheel and toner sensor. Go to step 3. 3 Replace the toner cartridge Problem solved. Go to step 4. for the color with the error. Did this fix the problem? 4 Test the sensors. Replace the Replace the printer controller affected toner While actuating the sensor, board. sensor. does the - Lexmark C912 | Service Manual - Page 60

and above: printhead Replace the LED printhead controller board for the affected color. and go to step 5. Did this resolve the problem? 5 Did replacement of the Problem solved. Replace the printhead controller board printer controller resolve the problem? board. 2-10 Service Manual - Lexmark C912 | Service Manual - Page 61

3 Did replacement of the Problem solved. Replace the printhead controller board printer controller correct the problem? board. 4 For serial number Problem solved. Replace the XX-1XXXX and above: printhead Replace the LED printhead controller board for the affected color. and go to step - Lexmark C912 | Service Manual - Page 62

and above: printhead Replace the LED printhead controller board for the affected color. and go to step 5. Did this resolve the problem? 5 Did replacement of the Problem solved. Replace the printhead controller board printer controller resolve the problem? board. 2-12 Service Manual - Lexmark C912 | Service Manual - Page 63

3 Did replacement of the Problem solved. Replace the printhead controller board printer controller correct the problem? board. 4 For serial number Problem solved. Replace the XX-1XXXX and above: printhead Replace the LED printhead controller board for the affected color. and go to step - Lexmark C912 | Service Manual - Page 64

934 - Color Drum Sensor Error 934 Service Drum Sensor Step Questions/actions Yes No 1 Is connector CN28 connected properly? 2 Clean the color drum sensor LED. Did this fix the problem? 3 Did replacing the color drum sensor fix the problem? Go to step 2. Problem solved. Problem solved. Plug - Lexmark C912 | Service Manual - Page 65

-Capacity Feed Sensor Error Step Questions/actions Yes No 1 Is connector CN40 on the Go to "High- Plug the printer controller board capacity feeder connector in connected properly? (HCF) service securely. check" on page 2-70. 941 - High-Capacity Feed Tray Error Step Questions/actions - Lexmark C912 | Service Manual - Page 66

Service Duplex Step Questions/actions Yes No 1 Is connector CN37 on the Replace the Plug the printer controller board printer controller connector in connected properly? board. securely. 945 - Engine Flash Error 945 Service Engine Flash Reflash the engine code. 946 - Printer/Printhead - Lexmark C912 | Service Manual - Page 67

ID Error 948 Service Machine ID Step Questions/actions Yes No 1 Turn the printer off and wait Problem solved. Verify proper 30 seconds. Turn the printer installation of the on. Did this fix the problem? EPROMs on both the printer controller board and the printhead controller board - Lexmark C912 | Service Manual - Page 68

the problem? board for trays 2-5. If the problem is with the highcapacity paper feeder, replace the HCPF board. 950 - Pr Control Board Replace the printer controller board. 952 - NVRAM Chip Failure 952 Service NVRAM Failure Step Questions/actions Yes No 1 Make sure the 80-pin RIP Replace - Lexmark C912 | Service Manual - Page 69

- Code CRC 955 Service Code CRC Replace the RIP board. 956 - Processor Failure 956 Service System Board Replace the RIP board. 957 - ASIC Failure Replace the RIP board. 958 - NAND Failure 958 Service NAND Failure Replace the RIP board. 960 - RAM Slot 1 Bad 960 Service RAM Memory Error Replace - Lexmark C912 | Service Manual - Page 70

5055-xxx 970 - Standard Network Error 970 Service Standard Network 970 Service Network Card x Check the network card in slot x on the RIP card. 975 - Unrecognizable Network Port Software error. 976 - Unrecoverable Software Error in Network Port Software error. Go to the "Options service check" on - Lexmark C912 | Service Manual - Page 71

980 - Face Up/Down Switching Error 980 Service Switch Error Check Area B 5055-xxx Step Questions/actions Yes No 1 Does the Face Up/Down Go to step 2. (FU/FD) deflector move at all during power up? 2 Manually operate the FU/ FD deflector. Go to step 3. Go to step 3. Go to step 4. Does it - Lexmark C912 | Service Manual - Page 72

5055-xxx 981 - Belt Up/Down Sensor Error 981 Service Switch Error Step Questions/actions Yes No 1 Is engine code level 41D or Go to step 2. above. Update the printer with code level 41D or above. If this dies not resolve the problem, continue with step 2. 2 Are connectors CN409 and Go to step - Lexmark C912 | Service Manual - Page 73

and +5 V between pins 7 and 8 of connector CN29 on the printer controller board? 7 Did replacing the belt up/ down clutch fix the problem? Problem solved. Replace the printer controller board. 982 - Sensor Controller Error 982 Service Sensor Control Step Questions/actions Yes 1 Turn the - Lexmark C912 | Service Manual - Page 74

this correct the problem? Problem solved. Go to step 4. 4 Replace the sensor card. Did this resolve the problem? Problem solved. Replace the drive unit. 984 - Yellow Gear Sensor Error Step Questions/actions Yes No 1 Is connector CN20 on the Go to step 2. printer controller board connected - Lexmark C912 | Service Manual - Page 75

CN29 on the Replace the Plug the printer controller board transfer belt unit. connector in connected properly? If the problem securely. remains, replace the printer controller board. 986 - Transparency (OHP) Sensor Error 986 Service OHP Sensor Step Questions/actions Yes No 1 Are - Lexmark C912 | Service Manual - Page 76

? 2 Replace the temperature and humidity sensor (a component of the paper feed solenoid assembly). Did this fix the problem? Go to step 2. Problem solved. Plug the connector in securely. Replace the printer controller board. 993 CPU Error Replace the printer controller board. 2-26 Service Manual - Lexmark C912 | Service Manual - Page 77

securely. 4 Is connector CN29 on the Replace the Plug the printer controller board density sensor. connector in connected properly? Go to step 5. securely. 5 Did replacing the density sensor fix the problem? Problem solved. Replace the printer controller board. Diagnostic information 2-27 - Lexmark C912 | Service Manual - Page 78

Service Finisher Step Questions/actions Yes No 1 Is there jammed paper or other obstructions in the paper path? Clear the paper dc (±10%) between pins 7 and 8 and +5 V dc (±10%) Problem solved. Replace the assembly. Did this resolve finisher control the problem? board. 2-28 Service Manual - Lexmark C912 | Service Manual - Page 79

5055-xxx Step Questions/actions Yes 6 Measure for +24 V dc Replace the between pins 1 and 2 on power supply. connector PJ3 on the finisher control board. Measure for +5 V dc between pins 1 and 3 on PJ2 on the finisher control board. Is either voltage missing? No Replace the finisher - Lexmark C912 | Service Manual - Page 80

6. Perform a continuity check on the cable for all positions. Is there continuity? Replace the cable. 6 Check for +24 V dc (±10%) Replace the Replace the between pins 1 and 2 of finisher control power supply. PJ3 on the finisher control board. board. Is +24 V dc present? 2-30 Service Manual - Lexmark C912 | Service Manual - Page 81

dc between pin 1 of tractor motor connector CN3 and frame ground. Is +24 V dc (±10%)? Go to step 5. 4 Replace the tractor motor Problem solved. Replace the assembly. Did this resolve finisher control the problem? board. 5 Disconnect CN3 and PJ4 Go to step 6. on the finisher control board and - Lexmark C912 | Service Manual - Page 82

Go to step 3. set switch is activated. elevator motor. Power the printer off. Measure for approximately +24 V dc (±10%) between pins 1 and 2 of connector CN4 at the tray elevator motor. Power the printer on and observe the voltage meter during the first 12 seconds of power up. Is +24 - Lexmark C912 | Service Manual - Page 83

Motor Error 5055-xxx Step Questions/actions Yes No 1 Are staples jammed in the Go to step 2. stapler? Go to step 3. 2 Clear the staple jam and run the staple test in diagnostic mode or run a staple job. Does the problem reoccur? Replace the staple cartridge and to go step 4. Problem solved - Lexmark C912 | Service Manual - Page 84

hardware failure, turn the printer off and back on. If the error recurs, turn the printer off, remove the specified device and call for service. If the error cannot be reset, go to "Map 10 Unrecoverable Check Tray (x) or Duplex Connection message" on page 2-60. The printer is deleting all job Wait - Lexmark C912 | Service Manual - Page 85

Open message" on page 2-54. Close Front Door The printer front door is open. Close the printer top door and front door. If the error cannot be reset go to "Map 2 - False Close Front Door message" on page 2-54. Close Tray The high-capacity feeder Top Cover door is open. Close the HCF door - Lexmark C912 | Service Manual - Page 86

complete. Formatting Flash The printer is formatting flash memory. Wait for the message to clear. Fuser Maintenance The counter that tracks wear on the fuser has reached its limit. • Press Go to continue printing. • If print quality is unacceptable, replace the fuser. 2-36 Service Manual - Lexmark C912 | Service Manual - Page 87

not fully inserted. Insert the specified tray. If the error cannot be reset, go to "Paper tray missing service check" on page 2-83. Install or Cancel Job The printer is requesting a specified device be installed so it can print. • Turn the printer off, install the specified device and - Lexmark C912 | Service Manual - Page 88

insertion of a single sheet into the manual feed slot. • Load a sheet of paper specified in the second line of the display in the manual feed tray or multipurpose feeder. • Press Select or Go to ignore the manual feed request and print on paper already in the printer. • Press Menu to open the Job - Lexmark C912 | Service Manual - Page 89

5055-xxx Message Meaning Action Network , Network interface is the active communication link, where represents printer was last turned off have not yet printed. Press Go to print the jobs. Press Return or Stop to delete jobs. Printer Calibrating The printer is adjusting the color - Lexmark C912 | Service Manual - Page 90

An error occurred while the printer was programming code into memory. Correct the problem specified on the second line of the display. Queuing and Deleting Jobs The printer is deleting one or Wait for the message to more held jobs and sending clear. one or more jobs to print. Queuing Jobs - Lexmark C912 | Service Manual - Page 91

bin is full. Remove the paper from the specified bin(s). Resetting Maint Cnt Value The printer is resetting the counter that tracks wear on the fuser. Wait for the message to clear. Resetting the Printer The printer is resetting to the current default settings. Any active print - Lexmark C912 | Service Manual - Page 92

version on the firmware card does not match the printer code version. Download the correct emulator version from Lexmark's Web site. The printer detects a paper jam. Clear the paper path. If the message cannot be reset, go to the "Paper carrying service check" on page 2-74. 2-42 Service Manual - Lexmark C912 | Service Manual - Page 93

the color print unit(s). If the message cannot be reset, go to "Map 6 - False Print Unit Missing message" on page 2-57. 32 Unsupported Cartridge The printer detects an Replace the cartridge. unsupported toner cartridge. 33 Tray Config Error The optional heavy media tray is - Lexmark C912 | Service Manual - Page 94

the current job. • Press Go to clear the message and continue printing. • Press Menu to open the Job Menu and cancel the current job. • Turn the printer off and then press and hold Go while turning it on, bypassing the code on the firmware card. • Remove the firmware card. 2-44 Service Manual - Lexmark C912 | Service Manual - Page 95

Action 40 Tray Size Sense Error 41 Open Bin 1 Exit Tray 51 Defective Flash 52 Flash Full 53 Unformatted Flash The high-capacity feeder detects an error in the size sensing mechanism. The printer wants to send paper to the bin 1 output tray, but the tray is closed. The printer detects defective - Lexmark C912 | Service Manual - Page 96

a serial interface error on a serial port. 54 Network Software Error The printer cannot establish communications with an installed network port. 54 Standard or Std Software Error 54 Std Par ENA Connection Lost The printer has lost the connection to an external print server. 54 Par - Lexmark C912 | Service Manual - Page 97

the excess trays. Plug the printer in and turn it on. 61 Defective Disk The printer detects a defective hard disk. • Press Go to clear the message and continue printing. • Install a different hard disk before you perform any operations that require one. 62 Disk Full Insufficient memory on - Lexmark C912 | Service Manual - Page 98

continue printing. The supplies message is displayed until you replace the transfer belt and fuser. Microcode in the engine flash code module has failed a system check. Press Go to clear the message and discard the code. Retransmit the microcode data from the host computer. 2-48 Service Manual - Lexmark C912 | Service Manual - Page 99

. Make sure you also install the new fuser coating roll that is included in each photodeveloper kit. Install a new black photodeveloper to clear the message and continue printing. Replace the black photodeveloper. Make sure you also install the new oil coating roll that is included in the kit. If - Lexmark C912 | Service Manual - Page 100

. 85 Coating Roll Coating roll is nearing it's Life Warning expected lift. If the print quality is still good, press Go to continue. Otherwise, replace the oil coating roll. 84 Photo Dev Abnormal Abnormal photodeveloper installed Install correct photodeveloper. 2-50 Service Manual - Lexmark C912 | Service Manual - Page 101

5055-xxx Message Replace Oil Coating Roll 88 Toner Empty 88 Toner Low Meaning Action A new black toner cartridge has been installed. This is a reminder to install a new oil coating roll. Press Go to clear or replace the oil coating roll with a new one. The printer has ceased - Lexmark C912 | Service Manual - Page 102

on the stacking tray inside the finisher and clear the paper jam in the printer. Press Go to clear the message and continue printing. Staples Empty Replace the staple cartridge if you want to continue stapling. You can press Go to clear the message and continue printing without stapling. Stapler - Lexmark C912 | Service Manual - Page 103

incorrectly. Correctly install the staple cartridge. Go to "Finisher service check" on page 2-71 to check the staple cartridge set sensor. Open the finisher stapler door, remove the paper from the accumulator, and remove the staple jam. Go to "210 Staple jam service check" on page 2-86. Diagnostic - Lexmark C912 | Service Manual - Page 104

printer controller board. printer controller door (turn guide) While activating the door board. sensor switch, is there continuity at assembly. pins 1 and 2 of the connector? Map 2 - False Close Front Door message Step Questions/actions Yes No 1 Close the top unit and front Problem - Lexmark C912 | Service Manual - Page 105

Map 3 - False Close Tray (x) Top Cover message 5055-xxx Step Questions/actions Yes 1 Remove the rear cover on Replace the the high-capacity feeder HCF card. and observe LED 9 on the HCF card while actuating the cover open micro- switch. Does the LED go on and off, while opening - Lexmark C912 | Service Manual - Page 106

the remaining sensor board for expansion the problem tray. Does this feeder control fix the problem? card. 5 Is the paper present flag operating correctly? Go to step 6. Repair or replace the failing parts. 6 Are connectors CN35 and Go to step 7. CN36 on the printer controller board - Lexmark C912 | Service Manual - Page 107

OCR contact at the Replace the rear of the fuser damaged fuser. or broken? Go to step 4. 4 Is CN44 on the printer controller board properly connected? Replace the printer controller board. Properly connect CN44. Map 6 - False Print Unit Missing message Step Questions/actions Yes No - Lexmark C912 | Service Manual - Page 108

dirt or paper dust? 3 Is the toner remaining photo interrupter sensor clean and free of obstructions? Go to step 4. Clean or replace the toner remaining photo interrupter. 4 Is the connector of the problem color properly connected on the printer controller board? Magenta Yellow Cyan Black CN18 - Lexmark C912 | Service Manual - Page 109

11 inch or paper size sensor 2 for A4. Map 9 - False 41 Open Bin 1 Exit Tray message Step Questions/actions Yes No 1 Is the exit tray switch actuator broken or damaged? Replace the paper exit tray. Go to step 2. 2 Disconnect CN31 from the Replace the Replace the printer controller board - Lexmark C912 | Service Manual - Page 110

Questions/actions Yes No 1 Is the problem with a specific paper tray or the duplex unit? Go to step 2. Go to step 8. 2 Is the problem with tray 1? Go to step 3. Go to step 6. 3 Are connectors CN 35 and Go to step 4. CN36 on the printer controller board properly connected? Properly connect - Lexmark C912 | Service Manual - Page 111

connector. 9 Are connectors CN101 and Go to step 10. CN102 on the duplex interface card properly connected? Properly connect the connectors. 10 Replace the duplex Problem solved. Return the interface card. Does this fix duplex interface the problem? card and go to step 11. 11 Replace the - Lexmark C912 | Service Manual - Page 112

1) on the printer controller board. CN4 on the expansion feeder control card (trays 2-5). 4 Replace the paper size sensor card. Does this fix the problem? Problem solved. Replace the printer controller board (tray 1). Replace the expansion feeder control card (trays 2-5). 2-62 Service Manual - Lexmark C912 | Service Manual - Page 113

Make sure the color print units are completely installed in the printer. Transparencies curl excessively. The printer seems slow to print. Go to the "Transfer belt up/down service check" on page 2-87. Make sure you're using the recommended Lexmark transparencies. Also be sure the paper delivery is - Lexmark C912 | Service Manual - Page 114

• Poor reproduction • Incorrect color image registration • Dirt on back of paper • Low image density • White and black lines and bands If your machine beeps 5 times and the screen is blank or all diamonds, replace the operator panel. Go to "Print quality problems" on page 2-88. 2-64 Service Manual - Lexmark C912 | Service Manual - Page 115

the toner and run a test print. • Transfer belt assembly • Transfer belt toner waste bottle • Transfer belt separation fingers • Fuser separation pawl Paper will not feed from MPF. Be sure you have paper in the MPF. Be sure the MPF paper present sensor connector (CN11) is connected to the printer - Lexmark C912 | Service Manual - Page 116

and the operator panel settings are different. Check the cable connections. Make sure your printer driver is set to direct the output to the bin you want. Printer settings selected from a software application or driver override default settings selected from the operator panel. 2-66 Service Manual - Lexmark C912 | Service Manual - Page 117

clear the paper jam message. The cover is not closed, finisher is against the printer, or there is paper somewhere in the paper path. paper. If you attempt to staple a larger stack of paper, the finisher ejects the stack without stapling it. Install a new staple cartridge. The stapler is jammed. - Lexmark C912 | Service Manual - Page 118

gear train for damage. Be sure the clutch on the gear train engages for color printing. Replace the drive 1 unit if necessary. If this does not correct the problem, replace the printer controller board. Drive 2 stepper motor service check FRU 1 Drive 2 stepper motor Action Be sure connector CN4 - Lexmark C912 | Service Manual - Page 119

paper feed service check If you have a "200 Paper Jam Tray (x)" error code, check the option connection cable for proper connection to the printer or other paper feeder. FRU 1 Feeder drive motor 2 • Gears • Feeder solenoid • Paper feed clutch • Expansion feeder control board Action If the feeder - Lexmark C912 | Service Manual - Page 120

Residual paper sensors 1-4 • Paper level sensor • Lower limit switch • Docking switch • Upper limit • Paper sensor switch • Paper feed sensor 2 • Tray motor • Paper feed motor • HCPF power supply • Pickup solenoid • Paper feed roller • Transfer roller • Paper feed clutch • Tray drive belt 3 • Paper - Lexmark C912 | Service Manual - Page 121

sensor Note: For frequent jams, hole punch • Paper register sensor problems or stapling problems. First check • Upper tray exit sensor the finisher to printer alignment. Go to • Guide stack assembly "Aligning the finisher and printer" on • Paper full A sensor page 3-80. • Paper detect sensor - Lexmark C912 | Service Manual - Page 122

.2 mm FRU / supply item Absorption/charge roller (transfer roller) Photodeveloper charge roller Supply roller (toner cartridge) Upper registration roller Lower registration roller Developer roller (toner cartridge) OCR (oil coating roller) Photodeveloper drum Fuser upper roller 2-72 Service Manual - Lexmark C912 | Service Manual - Page 123

marks 140 mm 824.5 mm 5055-xxx FRU / supply item Fuser lower roller Transfer belt Fuser part locations Thermistor hot roll Thermistor BUR TCO hot roll TCO BUR Detact fingers hot roll Detact fingers BUR Exit rollers Star rollers From paper center (mm) -6 0 66 101 113.5/75/37.5/0/-37.5/-75/-113 - Lexmark C912 | Service Manual - Page 124

service check Paper has not exited or is stopped in the high-capacity feeder (area F, 249). FRU 1 • Paper feed roller • Transfer roller 2 • Paper feed clutch • Paper feed motor • Sensors 3 • HCPF control card • HCPF power supply Action Be sure the paper feed roller transfer roller, reverse roller - Lexmark C912 | Service Manual - Page 125

cassette Be sure the paper cassette has the size guides and the side locator locks are working properly. Replace parts as necessary. 2 • Paper feed roller Be sure the paper feed rollers are free of dirt (MPF) and not damaged. • Paper feed rolls MPF, tray 1, 2, 3, 4, 5 Be sure the fanning - Lexmark C912 | Service Manual - Page 126

has stopped at the registration roller or has not reached the fuser (areas C, E, 240, 24x). FRU 1 • Registration roller clutch • Registration roller • Transfer belt unit • Rear paper feed guide 2 • Registration sensor • Printer controller board Action Check these parts for wear or damage. Replace - Lexmark C912 | Service Manual - Page 127

5055-xxx Paper has entered the fuser and exited the printer (area B). FRU Action 1 Fuser Remove any toner buildup and replace any worn or damaged parts. 2 • Fuser exit lower roller Be sure the exit FU/FD solenoid energizes • Fuser exit upper roller in the correct position for either face down - Lexmark C912 | Service Manual - Page 128

5055-xxx Paper has entered the duplex unit (area D). FRU Action 1 Feed rollers Belts Check for wear or damage to feed rollers and belts. 2 Duplex unit Be sure the duplex unit is properly installed and that all connections are correct. 3 • Duplex stopper motor Be sure the stepper motor turns - Lexmark C912 | Service Manual - Page 129

Paper jammed in finisher (area G). 5055-xxx FRU Action 1 • Registration roller • Paper exit rollers • Registration sensor • Registration clutch • Punch clutch punch unit Check finisher to printer alignment. Go to "Aligning the finisher and printer" on page 3-80. Check all belts for wear or - Lexmark C912 | Service Manual - Page 130

5055-xxx Paper jammed in finisher (area H). FRU Action 1 • Timing belts • Patting roller Check finisher to printer alignment. Go to "Aligning the finisher and printer" on page 3-80. Check for obstructions in the paper path. Check all belts for wear or damage. Check for wear or damage on the - Lexmark C912 | Service Manual - Page 131

Paper jammed (area I). 5055-xxx FRU 1 Timing belts 2 • Invert (tray 2) exit roller • Exit guide (tray 2) invert assembly • Exit guide (tray 1) straight assembly 3 • Paper exit sensor (tray1) • Paper exit sensor (tray 2) • Paper full sensor A (tray 2) • Paper upper level sensor B (tray 2) 4 • - Lexmark C912 | Service Manual - Page 132

5055-xxx Paper exit, face up service check FRU 1 Face up exit assembly 2 Printer controller board Action If the paper is not exiting to the back paper face up tray or the face down tray, check the sensor for proper operation by checking for a fluctuation of between 0 V and +5 V between pins 1 and - Lexmark C912 | Service Manual - Page 133

the guides. Reseat the roller at the leading edge of the transfer belt. Make sure the correct amount of paper is in the tray and that it is under the corner bucklers. The paper lift tray must be pushed down to the lock position every time the drawer is closed. Paper tray missing service check - Lexmark C912 | Service Manual - Page 134

replace the photodeveloper drum unit if necessary. Check the sensing contacts on the subframe assembly. Clean or replace the affected contacts or sub-frame. If the problem remains, replace the high voltage unit (HVU). If the problem remains, replace the printer controller board. 2-84 Service Manual - Lexmark C912 | Service Manual - Page 135

Power supply service check 5055-xxx FRU 1 Voltage 2 Power cord 3 • Fuse • Switch • Power supply 1 4 Power supply 2 Action Be sure the switch is on and the power cord is firmly plugged into the printer. Be sure the correct voltage is present at the outlet. Check the power cord for continuity. The - Lexmark C912 | Service Manual - Page 136

go into diagnostic mode, and run a staple test. If the problem reoccurs, replace the staple cartridge holder. If this does not resolve the problem, replace the stapler. If the error occurs and there is no staple jam, check to ensure that connectors CN5 on the stapler and PJ1 on the finisher control - Lexmark C912 | Service Manual - Page 137

Transfer belt up/down service check 5055-xxx FRU 1 Belt up/down sensors Belt up/down actuator 2 Belt up/down clutch 3 Belt up/down lift cams 4 Printer controller board Action Check the transfer belt up/down sensor. Be sure that connector CN29 is firmly connected to the printer controller board. - Lexmark C912 | Service Manual - Page 138

the correct Paper Weight setting for the media you're using. Be sure the affected print unit is completely installed in the printer. Set print darkness to 4 from the Color Menu. Clean the printhead LEDs. If you suspect a toner cartridge is low on toner, remove the appropriate toner cartridge and - Lexmark C912 | Service Manual - Page 139

black photodeveloper and fuser coating roll. If the problem occurs when printing one of the colors, replace all three of the color photodevelopers. If the problem remains, go to "Black line" on page 2-95. Toner specks appear on the page. Replace the oil coating roll. Toner colors the background - Lexmark C912 | Service Manual - Page 140

of the color photodevelopers and the transfer belt. If the problem remains, go to "Uneven printing" on page 2-97. Make sure the printer code is at EC2 level or later. The page is blank. Be sure the affected print unit is completely installed in the printer. Replace the affected toner cartridge. If - Lexmark C912 | Service Manual - Page 141

have selected the correct Paper Weight setting for the media you're using. Be sure the top cover is completely closed and both sides are snapped shut. You may need to replace the fuser. Print out a Menu Setting page and check the level of supplies. If a toner cartridge shows 10% or less, shaking the - Lexmark C912 | Service Manual - Page 142

the color that has a problem. If you switch the toner cartridges and the problem also changes color on the test pages, the problem is in one of the cartridges. Replace the proper color cartridge. Remove the fuser oil roll and wipe it with a dry, lint-free cloth, and clean the transfer belt. If - Lexmark C912 | Service Manual - Page 143

Be sure the width guides in the paper tray or the multipurpose feeder fit snugly against the media you loaded. Be sure the paper you load fits under the two corner tabs at the front of the tray. Be sure charge roll or belt is seated properly. Be sure all four corners of the printer are resting on - Lexmark C912 | Service Manual - Page 144

securely connected. If the problem remains, replace the high voltage unit. Be sure all connectors are securely connected to the printer controller board. If the problem remains, replace the printer controller board. If the problem remains, replace the printhead controller board. 2-94 Service Manual - Lexmark C912 | Service Manual - Page 145

scratched. Remove any toner buildup. Replace the fuser. Clean the LED printhead. Print a blank document. Replace the LED printhead if a black line appears on the paper. Action The printed paper has black print. Be sure the high voltage unit is properly connected. If the problem remains, replace the - Lexmark C912 | Service Manual - Page 146

Missing colors Possible cause Toner cartridge unit Photodeveloper High voltage unit LED printhead unit LED printhead controller board High voltage unit (HVU) Transfer belt unit Action Be sure the toner cartridge and the PC drum unit are properly seated. Be sure the contacts on the print unit are - Lexmark C912 | Service Manual - Page 147

Uneven printing Possible cause Photodeveloper LED printhead Transfer belt unit Top cover Periodic dirt Possible cause Oil coating fuser roller (OCR) Photoconductor drum Transfer belt unit White spots Possible cause • LED printhead • Photodeveloper • Toner cartridge Belt unit 5055-xxx Action Check - Lexmark C912 | Service Manual - Page 148

service check with the following exception: Run the "DRAM Memory Test" on page 3-12 from the menu if the DRAM Memory card assembly is correctly installed and not broken or damaged. If the test fails, replace the DRAM card assembly. If the problem continues, replace the RIP board. 2-98 Service Manual - Lexmark C912 | Service Manual - Page 149

on the interconnect board and is properly grounded. If you find no problem, contact your next level of support before replacing the network card. 54 Network Software Error This error displays when the RIP software detects that a network card is installed in slot x on the interconnect board but - Lexmark C912 | Service Manual - Page 150

5055-xxx 2-100 Service Manual - Lexmark C912 | Service Manual - Page 151

: • Paper jam • Printer cartridge unit • Toner supply • Paper cassette present 4. Fuser temperature check. Temperature regulated. 5. Ready: • Printer controller • RIP controller • Printer condition • Motor/Fan • Heater 6. DC motor drive 1 7. Feeding paper 8. Print 9. Stepper motor drive 2 10. Paper - Lexmark C912 | Service Manual - Page 152

a job. Indicator light State Off On Flashing Indicates Printer power is off. Printer is on, but idle. Printer is busy processing a job. Use the five operator panel buttons to open a menu, scroll through a list of values, select printer settings, and clear error messages. 3-2 Service Manual - Lexmark C912 | Service Manual - Page 153

is then displayed until you press Go to continue printer activity. For example, if you need to load paper in a tray while a job is printing, press Stop and wait for the printer motors to idle before removing the tray from the printer. Reinsert the loaded tray, and then press Go. Diagnostic aids 3-3 - Lexmark C912 | Service Manual - Page 154

Belt Block Photo Dev Coating Roll Color Photo Dev Toner Fuser Replace Supplies Supplies Life PAPER MENU Paper Source PAPER SIZE PAPER TYPE CUSTOM TYPES Configure Bins Assign Type/Bin Substitute Size Configure MP Paper Weight Paper Loading Universal Setup UTILITIES MENU Color Samples Print - Lexmark C912 | Service Manual - Page 155

Cancel Fax Confidential Job Held Job POSTSCRIPT MENU Print PS Error Font Priority Image Smoothing SETUP MENU Printer Language Printer Usage Power Saver Resource Save Download Target Print Timeout Auto Continue Wait Timeout Jam Recovery Page Protect Display Language Alarm Control Job Accounting - Lexmark C912 | Service Manual - Page 156

Return. 3. Turn on the printer. Release the buttons after the Performing Self Test message is displayed.The alignment menu displays first. 4. Press Select and using the menu key, scroll to Alignment Test. 5. Press Select to print the test. This prints the three color registration pages. These pages - Lexmark C912 | Service Manual - Page 157

5055-xxx Setting Printer Alignment 1. Press Menu until the color you want to adjust displays and then press Select. decremented, then the default value is changed and then the Alignment Test page is printed using the new value. The alignment test page should be printed on letter of A4 paper only. To - Lexmark C912 | Service Manual - Page 158

down the page. The images may be off by different amounts. Make the best overall judgement using all the radar images on the left side. 3-8 Service Manual - Lexmark C912 | Service Manual - Page 159

Theta drive the color radar image down the page. Do both the X and Y before attempting Theta. Use a loop or magnifying glass (4x or higher) to make the job easier. Yellow is very difficult. When you make the yellow adjustment, swap the cyan toner cartridge with the yellow cartridge. Run through the - Lexmark C912 | Service Manual - Page 160

: The Printing... Power indicator also blinks while the page prints. If Single is selected, no buttons are active while the Print Test page prints. If Continuous is selected, Return or Stop can be pressed to cancel the test, producing the following message: Canceling... 3-10 Service Manual - Lexmark C912 | Service Manual - Page 161

source> represents the input source selected for the Print Test. One of the following sources is displayed: Tray 1, MP feeder, standard bin (face-down), or Output Bin 1. The value of the field is displayed when the narrow media sensor determines the media used for the Quick Test is - Lexmark C912 | Service Manual - Page 162

Hardware Test causes the printer to continually execute the standard and optional). Patterns of data are written to DRAM verifying each bit in memory can be set and read correctly. When selecting this test from the operator panel, the printer finishes with errors. Initially 00000 displays for #####. The maximum fail - Lexmark C912 | Service Manual - Page 163

Test checks the validity of the RIP code and fonts. When this test is selected from the operator panel, the printer begins testing ROM memory and the ,999. F:##### represents the number of times the memory test finishes with errors. Initially 00000 displays for #####. The maximum fail count is 99,999 - Lexmark C912 | Service Manual - Page 164

Wrap, Parallel 1 Wrap). The printer begins testing the parallel hardware and the number of times the memory test finishes with errors. Initially 00000 displays for #####. The maximum blinks indicating the memory test is in process. The printer continually runs the same test until canceled from the - Lexmark C912 | Service Manual - Page 165

Error Init Fall Error Init Busy Error Init Rise Error Host Busy Error RAM Data FF Error RAM Data AA Error RAM Data 00 Error RAM Data 55 Error DMA Count Error DMA Address Error DMA Interrupt Error DMA Memory Error DMA Background Error Clear Init Rise Error False Init Rise Error False Init Fall Error - Lexmark C912 | Service Manual - Page 166

terminated by powering off the printer. Each time the test finishes, the screen is updated with the result. If the test is successful, the Pass Count increments by 1. If the test fails, a failure message displays for approximately three seconds and the Fail Count increments by 1. 3-16 Service Manual - Lexmark C912 | Service Manual - Page 167

Data Interrupt Error Transmit Empty Error Threshold Error Receive Data Ready Error Break Interrupt Error Framing Error Parity Error Overrun Error Data Error Data 232 Error Data 422 Error FIFO Error DSR Error DSR PIO Error DSR Interrupt Error CTS Error CTS PIO Error CTS Interrupt Error Press Return - Lexmark C912 | Service Manual - Page 168

docking safety switch with a non-metallic object. The interface cable with the printer controller board need not be connected. 2. Close the top cover or manually activate the cover switch. 3. Load paper. 4. Wait until the paper tray stops and the pickup solenoid turns off 5. With the cover closed or - Lexmark C912 | Service Manual - Page 169

10 11 12 13 Sensor Name Paper size sensor 1 switch (letter size 11 inches) Paper size sensor 1 switch (A4 size) Residual paper sensor 1 switch Residual paper sensor 2 switch Residual paper sensor 3 switch Residual paper sensor 4 switch Paper level sensor switch Lower limit switch Cover open sensor - Lexmark C912 | Service Manual - Page 170

correctly. To run the test, select the Sensor/Sw Test operation from the Finisher Tests top level menu. The following sensors and switches are listed in the bottom level menu: Input Path Paper Register Tray 1 Exit Tractor Home Pos. Paper Full A Paper Detect Staple Home Pos. 3-20 Service Manual - Lexmark C912 | Service Manual - Page 171

display OP - CL. • Tray 1 Exit-Activate the tray 1 exit sensor OP - CL. • Tractor Home Pos.-Activate the tractor home sensor by rotating the green paper clearing knob so that the tractor belt flag actuates the sensor. • Paper Full A-Activate the paper full A sensor by operating the sensor flag while - Lexmark C912 | Service Manual - Page 172

the jogging motor wheel. • Pap. Upper Level-Activate by operating the paper upper level sensor flag. • Fin. Set Switch-Activate by inserting a non-conductive tool into the opening below the staple door. • Staple Cart. Set-Activate by removing then inserting the staple cartridge. 3-22 Service Manual - Lexmark C912 | Service Manual - Page 173

5055-xxx Device tests Quick Disk Test The Quick Disk Test performs a non-destructive read/write on one block per track on the disk. The following message appears while the test is running: Quick Disk Test Testing... The Power indicator blinks while the test is in progress. If the test is successful, - Lexmark C912 | Service Manual - Page 174

message appears: Disk Test/Clean Test Failed Press Go, Return, or Stop to return to the DEVICE TESTS screen. You cannot cancel this test. 3-24 Service Manual - Lexmark C912 | Service Manual - Page 175

5055-xxx Flash Test The Flash Test writes and reads data to the flash device, destroying all data, leaving the flash unformatted. The servicer must reformat the flash using the Format Flash menu operation. To run this test, select Flash Test from the DEVICE TESTS menu. The following message - Lexmark C912 | Service Manual - Page 176

5055-xxx Diagnostics - printer setup Defaults The following printer settings are used to determine whether U.S. or non-U.S. factory defaults should be used: • = U.S. * • = Non U.S. Light Quantity • Cyan • Magenta • Yellow • Black Range = 0 to 45 If you replace one or more of the printheads, or the - Lexmark C912 | Service Manual - Page 177

xxx Par S Strobe Adj This message displays only if the printer is configured with the standard parallel port. Par 1 Strobe Adj This message displays only if a parallel port is available through PCI slot 3. Auto Color Adj • = On * • = OFF Reset Calibration Press Select to reset. Diagnostic aids 3-27 - Lexmark C912 | Service Manual - Page 178

The drum counter for a particular plane increments (if that color is printed), by 1 for Letter, A4, A5, B5 and envelopes, and by 1.2 for Legal and B4. It increments by 2 for 11 x 17, 12 x 18 (C912 only), and A3. The counters are used to track printer usage. The current value of the drum counter may - Lexmark C912 | Service Manual - Page 179

Count The page count can be changed through the Diagnostic menus. The servicer uses this menu to reset the page count whenever the engine board, containing NVRAM memory, is replaced. When Page Count is selected from the PRINTER SETUP menu, the current page count is displayed as follows: Page Count - Lexmark C912 | Service Manual - Page 180

displays. If the ID is valid, it is stored in NVRAM and the printer automatically activates the new setting. If a configuration ID has not been set, then upon entry into diagnostics, the configuration ID setup is the only Diagnostic function displayed until a valid ID is entered. 3-30 Service Manual - Lexmark C912 | Service Manual - Page 181

925 service error occurs. If an error occurs after the log is full, the oldest error in the log is discarded to make room for the new error. The printer stores identical errors in consecutive positions in the log. The following error messages are stored in the error log: • All 2xx paper jam messages - Lexmark C912 | Service Manual - Page 182

, Return, or Stop to exit the Clear Log menu. Maintenance Menu 80 Fuser Maint = 0 to xxxxxxx Reset 80 Fuser =Yes 80 Belt Maint = 0 to xxxxxxx Reset Belt Maint =Yes Exiting Diagnostics Mode To exit diagnostics mode and POR the printer into normal user mode, press EXIT DIAGNOSTICS. 3-32 Service Manual - Lexmark C912 | Service Manual - Page 183

printer, the toner of four colors (magenta, cyan, yellow and black) melts and deposits dots on paper, which record color image information. This printing from the LED printhead, forming the electrostatic image. The LED printhead array along with the Selfoc lens array provide a single-dot line of the - Lexmark C912 | Service Manual - Page 184

per the voltage of the development roll. Transfer unit Paper feeds electrostatically by the transfer belt and is carried to the transfer unit which turn at the speed of the photodeveloper drum. A charge roller applies a positive charge to the paper. The toner image formed on the photoconductor drum - Lexmark C912 | Service Manual - Page 185

paper, stands by, drives the belt unit, separates, fuses, feeds the face up delivery unit, and drives the photodevelopers and toner cartridge by rotations of the dc motor. Drive 2 drives the face down delivery unit by rotations of the stepper motor. The expansion paper feeder and the duplex unit - Lexmark C912 | Service Manual - Page 186

a 100 V dc motor and gear unit, feeds the registration paper from the paper feeder and drives the belt unit, photodevelopers / toner cartridge, fusing unit, and face-up delivery unit. The motor rotates by the ON signal from the printer controller/motor drive unit and sends a rotation synchronization - Lexmark C912 | Service Manual - Page 187

the printer a maximum paper supply of up to 5,850 sheets. Cassette paper feeder The paper feeding solenoid turns on by the signal from the printer controller. The paper feeding roller interconnected with drive 1, rotates with the spring clutch and picks the paper in the paper cassette. Diagnostic - Lexmark C912 | Service Manual - Page 188

a registration clutch which feeds or stops the paper. In the forward direction of the registration roll, a registration sensor (photo interrupter) is provided to detect paper fed from the paper feeder and to stop paper jam feeding. Registration Sensor Registration Roller 3-38 Service Manual - Lexmark C912 | Service Manual - Page 189

5055-xxx Separation unit The transfer belt and paper are separated with the belt drive roll by separation fingers. Drive Roll Paper Separation Fingers Diagnostic aids 3-39 - Lexmark C912 | Service Manual - Page 190

printer controller. The printer controller turns the heater on or off according to the voltage of each thermistor. If the controller fails and the temperature of the roller exceeds specifications, the temperature fuse (TCO) connected to each heater opens, preventing overheating. 3-40 Service Manual - Lexmark C912 | Service Manual - Page 191

-up and face-down paper delivery. The paper from the fuser pulls down the sensing lever turning on the delivery sensor (photo interrupter). If the delivery unit remains on longer than specified, the printer controller determines that the printer is jammed, and the paper delivery flap lever switches - Lexmark C912 | Service Manual - Page 192

the belt unit is replaced. The transfer belt is conductive and seamless. If the transfer belt is damaged, toner can cling to the belt and contaminate the paper. When fingerprints or other stains appear on the belt, wipe them away with a dry cloth or cloth moistened with alcohol. A density sensor is - Lexmark C912 | Service Manual - Page 193

sensor, using the fan shaped light blocking plate attached to the switching shaft. Printing with the transfer belt lowered is called monochrome mode and color printing is called color mode. Expansion paper feeder The optional expansion paper feeder can be installed at the lower part of the main unit - Lexmark C912 | Service Manual - Page 194

the duplex unit stops once, and the center position is corrected by the operation of the side guide plate. Paper is then refed by the printer controller signal to the main unit, and, following printing on the back side, is delivered to the normal feeding path. When non-offset type color toner is - Lexmark C912 | Service Manual - Page 195

Paper weight Purpose: To identify the relative weight of the paper loaded in a specific source and ensure that the toner adheres properly to the printed page. Values: Plain weight Preprint weight Card stock weight Colored weight Transparency weight Custom weight Bond weight Labels weight - Lexmark C912 | Service Manual - Page 196

Check Areas A, B This message indicates a paper jam in the transfer belt, fuser, or output roller area. To clear areas A-B: 1. Open the front door. 2. Rotate the top cover locking lever to the left. 3. Place both hands on the lifting points and squeeze the right top cover latch. 3-46 Service Manual - Lexmark C912 | Service Manual - Page 197

toner, which can stain garments. 5. Remove any paper on the transfer belt. If the paper source was the multipurpose feeder, check the area between the multipurpose feeder and the transfer belt. 6. Check the fuser area and top cover for additional jams. If there is no jammed paper in the fuser area - Lexmark C912 | Service Manual - Page 198

access door on the right side of the printer. 2. Remove the jam. 3. Press Go. If the paper jam message continues, clear any paper from the paper path. Check Area D This message indicates a paper jam in the duplex unit area. To clear area D: 1. Open the duplex jam access door on the right side of the - Lexmark C912 | Service Manual - Page 199

access door on the bottom drawer. 8. Remove the jam. 9. Close the door. 10. Press Go. If the paper jam message continues, clear any paper from the paper path. Check Area F 1. Pull the high capacity feeder away from the printer. 2. Open the jam access door on the top optional drawer. 3. Remove any - Lexmark C912 | Service Manual - Page 200

paper on the transfer belt. 7. Place both hands on the top cover. 8. Press down firmly until the top cover clicks. 9. Rotate the top cover locking lever to the right. If you cannot rotate the locking lever, the cover is not fully closed. 10. Close the front door. 11. Press Go. 3-50 Service Manual - Lexmark C912 | Service Manual - Page 201

clicks. 8. Close the paper tray. 9. Press Go. If the paper jam message continues, clear any paper from the paper path. 249 Paper Jam Note: If you have an optional printer cabinet, the high capacity feeder will be identified as tray 3. A 249 Paper Jam Check Tray 5 message indicates a jam in the high - Lexmark C912 | Service Manual - Page 202

-capacity feeder consists of a tray and paper transfer mechanisms. The paper feed and separation mechanism uses a friction roller separation and paper feed system with a non-contact magnet type maintenance-free torque limiter. When the paper feed clutch turns on, the paper feed roller shaft rotates - Lexmark C912 | Service Manual - Page 203

5055-xxx Registration operation When the paper feed motor rotates, the transfer roller is driven with relay gears. The reverse roller shaft rotates the gears on the paper feed clutch in the direction of the arrow and stops by the friction force of the paper feed roller. Diagnostic aids 3-53 - Lexmark C912 | Service Manual - Page 204

paper loads, and the top cover is set, the pickup solenoid turns on to lower the call roller. When the tray moves up, the call roller is raised by the top surface of the paper, and the shield plate on the up sensor is released from the up sensor which turns off the tray motor. 3-54 Service Manual - Lexmark C912 | Service Manual - Page 205

paper lowers during printing and the up sensor is shielded, the tray motor again rotates forward to raise the paper. When the down button is pressed, the tray motor reverses to move the tray down. During the down motion of the tray, as the top surface of paper passes the paper level sensor, the tray - Lexmark C912 | Service Manual - Page 206

down sensor detects the tray lower limit position. Tray up condition Tray up motion stops when the: • Up sensor is OFF (not shielded) • Power cord is connected and the joint switch is ON • Up sensor is ON (shielded) during printing • Top cover is closed, or when up sensor is ON 3-56 Service Manual - Lexmark C912 | Service Manual - Page 207

Size detection mechanism The paper size can be switched between A4 and letter (11 inches) by changing the side fence position. The paper size sensor 2 detects the fixing screw 2 at the A4 position. The paper size sensor 1 detects the fixing screw 1 at the letter position. Tray up motion stops when - Lexmark C912 | Service Manual - Page 208

detection mechanism The residual paper quantity in the tray is detected with four photo interrupters. The quantity of pages remaining in the sheet feeder displays in the following increments: • Near end, about 80 sheets • About 300 sheets • About 1,000 sheets • About 2,000 sheets 3-58 Service Manual - Lexmark C912 | Service Manual - Page 209

5055-xxx Paper end detection A reflection type sensor is provided on the top stay to detect the paper top surface and the paper end. Diagnostic aids 3-59 - Lexmark C912 | Service Manual - Page 210

X 1 Standard machine initial setting 2 Optional machine initial setting • Maintenance switch (test mode selection) is valid without connecting to the printer controller board. DIP switch OFF ON OFF ON OFF ON OFF ON Function switch 4 3 Maintenance switch 2 1 Test paper feed mode (standalone - Lexmark C912 | Service Manual - Page 211

the accumulated number of sheets reaches a designated number, it staples a batch of sheets, and then exits the stapled set to the lower tray. • Punch, invert and staple-stops paper at the leading edge, punches it, sends it to the accumulator and jogs each sheet. When the accumulated number of sheets - Lexmark C912 | Service Manual - Page 212

5055-xxx 3-62 Service Manual - Lexmark C912 | Service Manual - Page 213

Finisher cross section Upper Tray Paddle Roller Straight Exit Roller Invert Exit Idle Roller Lower Tray Invert Exit Roller 5055-xxx Straight Exit Idle Roller Path Select Gate Register Idle Roller Input Paper Guide Register Roller Accumulator Stapler Unit Diagnostic aids 3-63 - Lexmark C912 | Service Manual - Page 214

• Paper Exit Sensor (Upper Tray) (Letter), Invert Path Sensor (A4)-detects when paper feeds into the lower tray, the end of jogged paper and paper jams. • Paper Exit Sensor-detects that paper has exited the printer. • Tractor Home Position Sensor-locates home position for the drive belt. • Elevator - Lexmark C912 | Service Manual - Page 215

, after it is detected at paper register sensor by drive gears and drive belts, driven by the paper feed motor or tractor drive motor and other rollers. Paper path route differs subject to the selected mode. Straight paper path (exit paper to upper tray) Paper feed motor drives and rotates - Lexmark C912 | Service Manual - Page 216

5055-xxx Path select gate 3-66 Service Manual - Lexmark C912 | Service Manual - Page 217

gate, and patting rollers. Paper is detected by the invert path sensor. Paper is then jogged by jogging bar and driven by the belt drive motor before exiting to the lower tray (accumulator). Patting Roller Path Select Gate Invert Exit Idle Roller Paper Registration Sensor Lower Tray Invert Exit - Lexmark C912 | Service Manual - Page 218

at the entrance. The paper buckle feeds downward to the lower entrance paper guide, where it is hole-punched at the leading edge. The paper standstill clutch turns OFF and changes to close as the driving force transmits to register rollers and the paper transportation restarts. 3-68 Service Manual - Lexmark C912 | Service Manual - Page 219

cam causes the paper to be hole-punched. Immediately after one turn of the shaft, the punch clutch turns OFF, and the drive shaft stops. Drive Shaft Cover Cover Paper Entrance Sensor Punch Clutch Registration Idler Roller Blade Cam Registration Roller Registration Clutch Diagnostic aids 3-69 - Lexmark C912 | Service Manual - Page 220

of the sheet contacts the registration plate. The paper detecting sensor detects the paper position for stapling. Offsetting sequence Sheets of jogged paper are offset by the horizontal movement of the . The distance of the offset bar movement depends on paper size, A4 or letter. 3-70 Service Manual - Lexmark C912 | Service Manual - Page 221

elevator upper limit sensor is ON, the paper feeds onto the tray, or until the paper upper level sensor B is ON if no paper feeds onto the tray. When paper feeds out to the lower tray and the paper full sensor A turns ON, the lower tray moves down until the paper full sensor A Diagnostic aids 3-71 - Lexmark C912 | Service Manual - Page 222

paper is removed from the lower tray and the paper upper level sensor B turns OFF, the lower tray moves up. Paper Full Sensor A Belt Paper Upper Level Sensor B Wire Hook Plate Elevator Upper Limit Sensor Belt Drive Motor Elevator Lower Limit Sensor Wire Drum Elevating Motor 3-72 Service Manual - Lexmark C912 | Service Manual - Page 223

5055-xxx Finisher installation Attaching the docking plate and guide rail 1. Lift the printer exit tray halfway and remove. You will need the tray when the finisher is attached. 2. Insert the docking plate tabs into the printer. 3. Align the thumbscrews on the docking plate with the holes in the - Lexmark C912 | Service Manual - Page 224

5055-xxx 6. Tighten the guide rail plate thumbscrews. 7. Align the thumbscrews on the guide rail with the holes in the guide rail plate. 8. Tighten the guide rail thumbscrews. 3-74 Service Manual - Lexmark C912 | Service Manual - Page 225

5055-xxx Combining the finisher and stand 1. Roll the finisher stand onto the guide rail. Do not push the stand all the way up against the printer. 2. Remove and discard all shipping tape, packing material, and the metal shipping bracket. CAUTION: The finisher weighs 19.7 kg (42.2 lb). Diagnostic - Lexmark C912 | Service Manual - Page 226

5055-xxx 3. Open the stapler door. 4. Remove all shipping tape and packing material. 5. Lift the stapler locking lever. 6. Raise the stapler. 7. Remove all shipping tape and packing material. 3-76 Service Manual - Lexmark C912 | Service Manual - Page 227

8. Close the stapler. 5055-xxx 9. Close the stapler door. 10. Align the two sockets on the bottom of the finisher with the legs of the finisher stand. Diagnostic aids 3-77 - Lexmark C912 | Service Manual - Page 228

5055-xxx 11. Lower the finisher onto the finisher stand. CAUTION: When assembled, the finisher weighs 26.3 kg (56.9lb) and requires at least two people to lift it safely. 12. Remove both thumbscrew spacers. 13. Tighten the two thumbscrews. 3-78 Service Manual - Lexmark C912 | Service Manual - Page 229

the metal brackets on the rear of the finisher. 2. Slide the bin down onto the metal brackets until it is fully seated. Note: When assembled, the finisher and finisher stand are referred to as the finisher. 3. Align the tabs on bin 1 with the slots on the rear of the finisher. 4. Lower the - Lexmark C912 | Service Manual - Page 230

5055-xxx Aligning the finisher and printer The following three areas must align properly to prevent paper jams. 1. The docking plate pins must enter the holes in the finisher. 2. The space between the printer and finisher must be the same at the top and bottom of the finisher. 3. The alignment marks - Lexmark C912 | Service Manual - Page 231

5055-xxx 4. Roll the finisher toward the printer until the finisher locks to the docking plate pins. You hear a click when the finisher locks into position. If to "Lowering or raising the finisher" on page 3-82. Otherwise, go to "Aligning the sides of the finisher" on page 3-84. Diagnostic aids 3-81 - Lexmark C912 | Service Manual - Page 232

5055-xxx Lowering or raising the finisher Follow these instructions if the holes on the finisher are above or below the pins on the docking plate. 1. Determine if the pins are above or below the holes in the finisher. 2. Loosen the guide rail thumbscrews. 3-82 Service Manual - Lexmark C912 | Service Manual - Page 233

. • To lower the finisher, rotate the adjustment knobs counterclockwise. 4. Roll the finisher toward the printer until the finisher locks to the docking plate pins. You hear a click of the finisher" on page 3-84. Otherwise, go to "Aligning the top of the finisher" on page 3-86. Diagnostic aids 3-83 - Lexmark C912 | Service Manual - Page 234

Aligning the sides of the finisher Follow these instructions if the distance between the finisher and printer is not the same at the top and bottom. 1. Loosen the guide rail thumbscrews. If you previously lowered or raised the guide rail plate, the thumbscrews are already loose. 3-84 Service Manual - Lexmark C912 | Service Manual - Page 235

rotate the adjustment knobs clockwise. • To move the top of the finisher away from the printer, rotate the adjustment knobs counterclockwise. 3. Roll the finisher toward the printer until the finisher locks to the docking plate pins. You hear a click when the finisher locks into position. Diagnostic - Lexmark C912 | Service Manual - Page 236

printer or finisher, recheck the printer and finisher top alignment. Follow these instructions if the alignment marks on top of the finisher are not aligned with the edges of the cover on the side of the printer. 1. Loosen the guide . 3. Tighten the guide rail thumbscrews. 3-86 Service Manual - Lexmark C912 | Service Manual - Page 237

5055-xxx 4. Roll the finisher toward the printer until the finisher locks to the docking pins. You hear a click when the finisher locks into position. Diagnostic aids 3-87 - Lexmark C912 | Service Manual - Page 238

the floor. To lower the wheels, rotate the adjustment knobs clockwise. 2. Turn the wheels until the locking knobs are aligned with the finisher base. 3-88 Service Manual - Lexmark C912 | Service Manual - Page 239

5055-xxx 3. Rotate the locking knobs counterclockwise until they contact the finisher base. Diagnostic aids 3-89 - Lexmark C912 | Service Manual - Page 240

the finisher to the printer, and the Y-power cord provides electrical power to the finisher and printer. 1. Turn the printer off and unplug the power cord from the power outlet. 2. Push the latch in and hold it. 3. Roll the finisher away from the printer. 4. Release the latch. 3-90 Service Manual - Lexmark C912 | Service Manual - Page 241

is turned off before continuing. 1. Plug the interface cable into the bottom connector on the back of the printer. 2. Tighten the thumbscrews. 3. Plug the interface cable into the connector on the side of the finisher. The plug will be on a slight angle when connected. 4. - Lexmark C912 | Service Manual - Page 242