LiftMaster 3900 3900PLD Manual - Page 9

Installation Step 4 - operator

|

View all LiftMaster 3900 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 9 highlights

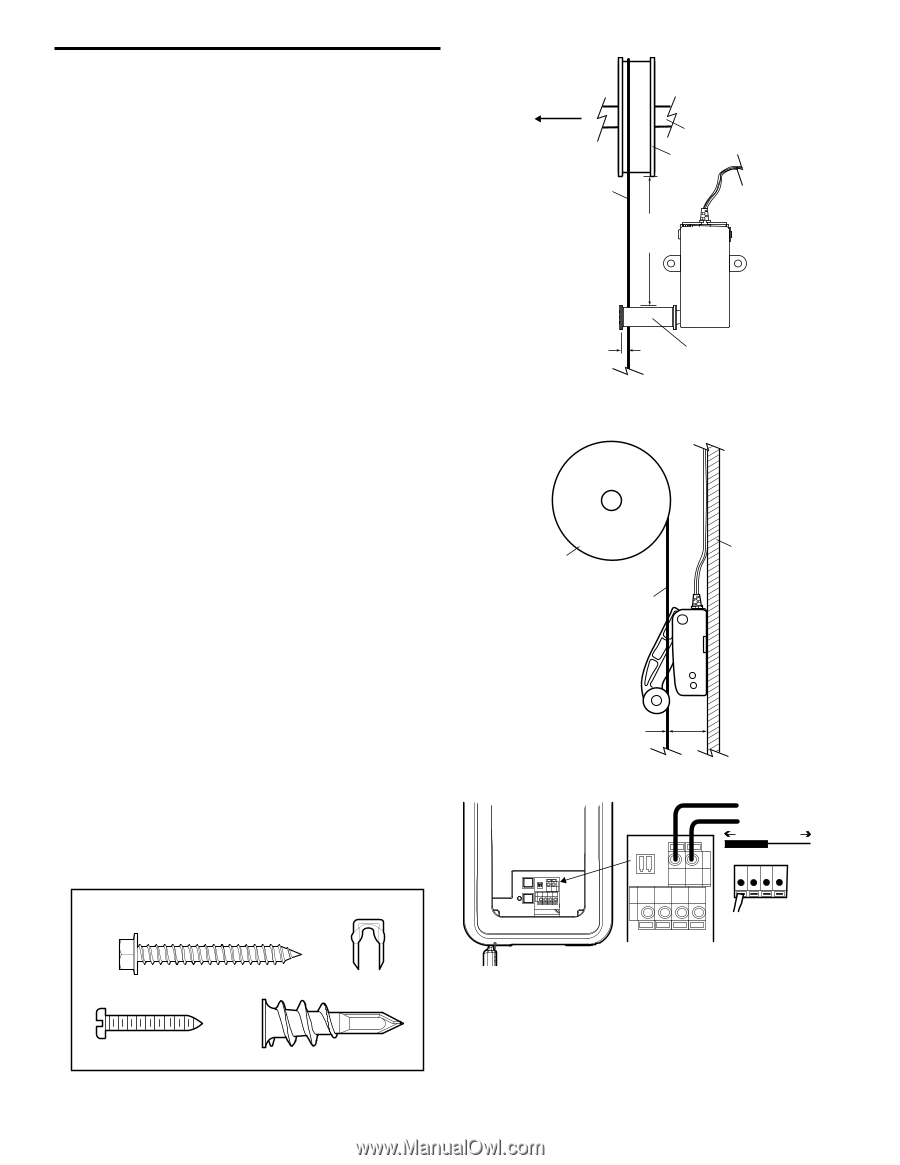

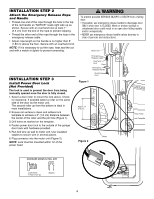

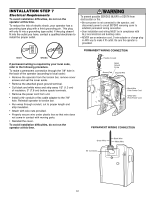

INSTALLATION STEP 4 Attach the Cable Tension Monitor (Required) This operator comes standard with the cable tension monitor. It is supplied as a device to monitor the cables for ANY slack that may occur and will reverse the door when excessive slack is detected, eliminating service calls. The cable tension monitor MUST be connected and properly installed before the door operator will move in the down direction. NOTE: The cable tension monitor is shipped for left side installation. It is preferred that the cable tension monitor be installed on the same side of the door as the operator. If required, it can be mounted on the opposite side of door. Remove the snap-ring holding the roller in place and reassemble it on the opposite side of the cable tension monitor. 1. Position the cable tension monitor as shown (Figures 1 and 2). The cable tension monitor should be located as close to the drum as possible. NOTE: There must be no obstructions in the installation area that prevent the cable tension monitor or the cable itself from closing completely when slack is detected. 2. Make sure cable tension monitor is located over a wood support member. NOTE: If the cable tension monitor can not be mounted into wood with the lag screws provided, it can be mounted into 1/2" or greater drywall using the wall anchors (2) and the #8 hex head screws (2) provided in the hardware bag. 3. Mark and drill 3/16" pilot holes for screws (pilot holes are not required for anchors). 4. Attach the cable tension monitor to the wall using the hardware provided. Make sure that the roller is on top of the cable. 5. Run bell wire to operator. Use insulated staples to secure wire in several places. 6. Connect bell wire to the green quick-connect terminals (polarity is not important) (Figure 3). NOTE: Cable must have tension through entire travel. Make sure there is no slack in cable on opposite side of door during normal operation. If this condition exists, adjust cables as required. Figure 1 Operator Torsion Bar Drum Cable 2"-6" (5 cm15 cm) Cable Tension Monitor 1/8"-1/4" (3 mm-6 mm) Cable Tension Monitor Roller With Door Closed Preferred Orientation Figure 2 Wall Drum Cable Figure 3 3/4" Min. (18 mm Min.) WHT/GRN WHT/GRN Cable Tension Monitor 7/16" (11mm) Strip wire 7/16" (11mm) HARDWARE SHOWN ACTUAL SIZE #8 Hex Head Screw (2) Staples To insert or release wire, push in tab with screwdriver tip Screw #6 (2) Wall Anchor (2) 9