Makita GA4534 Owners Manual - Page 9

Operation with abrasive cut-off / diamond, wheel optional accessory - angle grinder

|

View all Makita GA4534 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 9 highlights

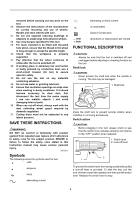

In general, keep the edge of the wheel or disc at an angle of about 15 degrees to the workpiece surface. During the break-in period with a new wheel, do not work the grinder in the B direction or it will cut into the workpiece. Once the edge of the wheel has been rounded off by use, the wheel may be worked in both A and B direction. Operation with abrasive cut-off / diamond wheel (optional accessory) 1 1. Lock nut 2 2. Abrasive cut-off wheel/diamond 3 wheel 4 3. Inner flange 4. Wheel guard for abrasive cut-off wheel/diamond wheel 010799 The direction for mounting the lock nut and the inner flange varies by wheel thickness. Refer to the table below. 100 mm (4") Abrasive cut-off wheel Diamond wheel Thickness: Less than 4 mm (5/32") 1 Thickness: 4 mm (5/32") or more 2 16 mm (5/8") 3 16 mm (5/8") Thickness: Less than 4 mm (5/32") Thickness: 4 mm (5/32") or more 1 4 20 mm (13/16") 3 20 mm (13/16") 1. Lock nut 2. Abrasive cut-off wheel 3. Inner flange 4. Diamond wheel 115 mm (4 - 1/2") / 125 mm (5") Abrasive cut-off wheel Diamond wheel Thickness: Less than 4 mm (5/32") Thickness: 4 mm (5/32") or more 1 Thickness: Less than 4 mm (5/32") Thickness: 4 mm (5/32") or more 1 2 4 22.23 mm (7/8") 22.23 mm (7/8") 3 22.23 mm (7/8") 3 22.23 mm (7/8") 1. Lock nut 2. Abrasive cut-off wheel 3. Inner flange 4. Diamond wheel 010848 WARNING: • When using an abrasive cut-off / diamond wheel, be sure to use only the special wheel guard designed for use with cut-off wheels. • NEVER use cut-off wheel for side grinding. • Do not "jam" the wheel or apply excessive pressure. Do not attempt to make an excessive depth of cut. Overstressing the wheel increases the loading and susceptibility to twisting or binding of the wheel in the cut and the possibility of kickback, wheel breakage and overheating of the motor may occur. • Do not start the cutting operation in the workpiece. Let the wheel reach full speed and carefully enter into the cut moving the tool forward over the 9