Maytag MHW5630MB Owners Manual - Page 15

Level WasherComplete Installation Checklist, Connect inlet hoses to washer, Check for leaks

|

View all Maytag MHW5630MB manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 15 highlights

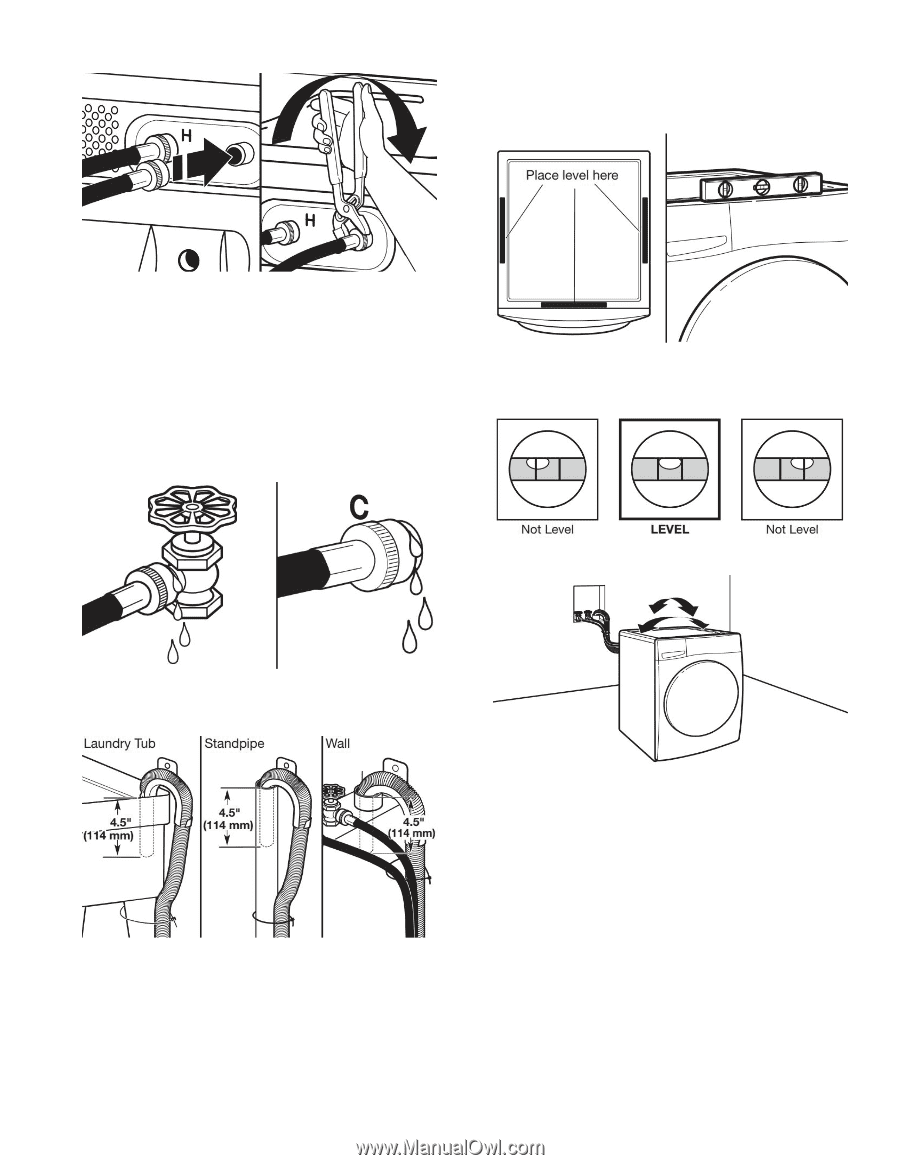

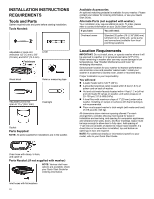

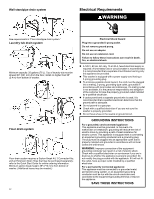

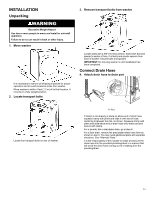

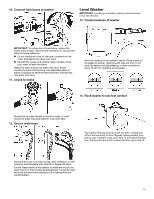

10. Connect inlet hoses to washer Level Washer IMPORTANT: Leveling your washer properly reduces excess noise and vibration. 13. Check levelness of washer IMPORTANT: To reduce risk of hose failure, replace the hoses every 5 years. Record hose installation or replacement dates for future reference. � Do not overtighten hose or use tape or sealants on the valve. Damage to the valves can result. � Periodically inspect and replace hoses if bulges, kinks, cuts, wear, or leaks are found. Attach hot water hose to hot water inlet valve. Screw coupling by hand until it is snug. Use adjustable pliers to tighten couplings an additional two-thirds turn. Repeat with cold water inlet valve. 11. Check for leaks Remove cardboard from beneath washer. Place a level on top edges of washer, checking each side and front. If not level, tip washer and adjust feet up or down as shown in steps 15 and 16, repeating as necessary. 14. Rock washer to test foot contact Slowly turn on water faucets to check for leaks. A small amount of water may enter washer. It will drain later. 12. Secure drain hose Grip washer from top and rock back and forth, making sure all four feet are firmly on floor. Repeat, rocking washer from side to side. If washer rocks, go to step 15 and adjust leveling feet. If all four feet are in firm contact with floor, go to step 16. Secure drain hose to laundry tub leg, drain standpipe, or inlet hoses for wall standpipe with cable tie or beaded tie strap. It is the responsibility of the installer to install and secure the drain hose in to the provided plumbing/drain in a manner that will avoid the drain hose coming out of or leaking from the plumbing/drain. 15