Rheem RAPM-JAZ Specifications - Page 3

Model Features

|

View all Rheem RAPM-JAZ manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 3 highlights

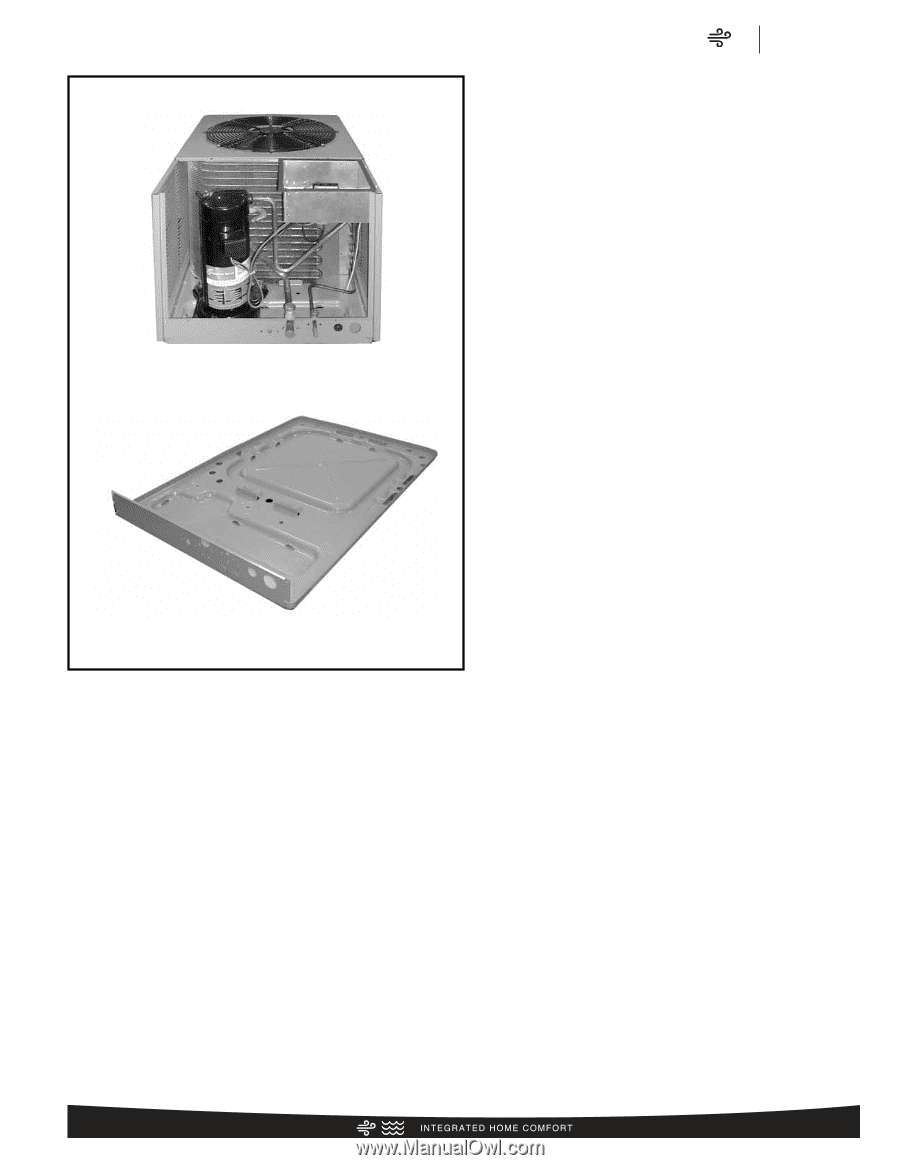

All controls and compressor are accessible for servicing by removal of the service panel. Drawn Painted Base Pan. Model Features Air RAPM- JAZ Series Model Features RAPM- Series Condensing Units 1. This unit contains a special scroll compressor that is designed specifically to operate with R-410A refrigerants and polyolester (POE) oils. The compressor is hermetically sealed and incorporates internal high temperature motor overload protection and durable insulation on the motor windings. It is externally mounted on rubber grommets to reduce vibration and noise. 2. Compressors have an internal pressure relief assembly to protect against excessive pressure differential. 3. All refrigerant connections are on the exterior of the unit, located close to the ground for neat appearing installations. 4. Cabinet is constructed of powder painted galvanized steel. The full wraparound louvered grille protects the coil from damage. 5. Copper tube-aluminum fin coils are used on all models. 6. The control box is located in the top corner of the cabinet providing for easy access through a service panel. 7. Service valves are standard on all models. 8. Power and control wiring are kept separate. 9. Every unit is factory charged and tested. 10. Separate compressor compartment for easy service access. 11. Drawn, painted base pan for extra corrosion resistance and sound reduction. 12. Automatic reset high and low pressure controls are standard on all models. 13. A liquid line filter drier is standard on all models (shipped - not installed). 3