Bosch 1347A Operating Instructions - Page 8

Sanding Accessories Assembly, Masonry Cutting Wheel Assembly

|

UPC - 000346017571

View all Bosch 1347A manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 8 highlights

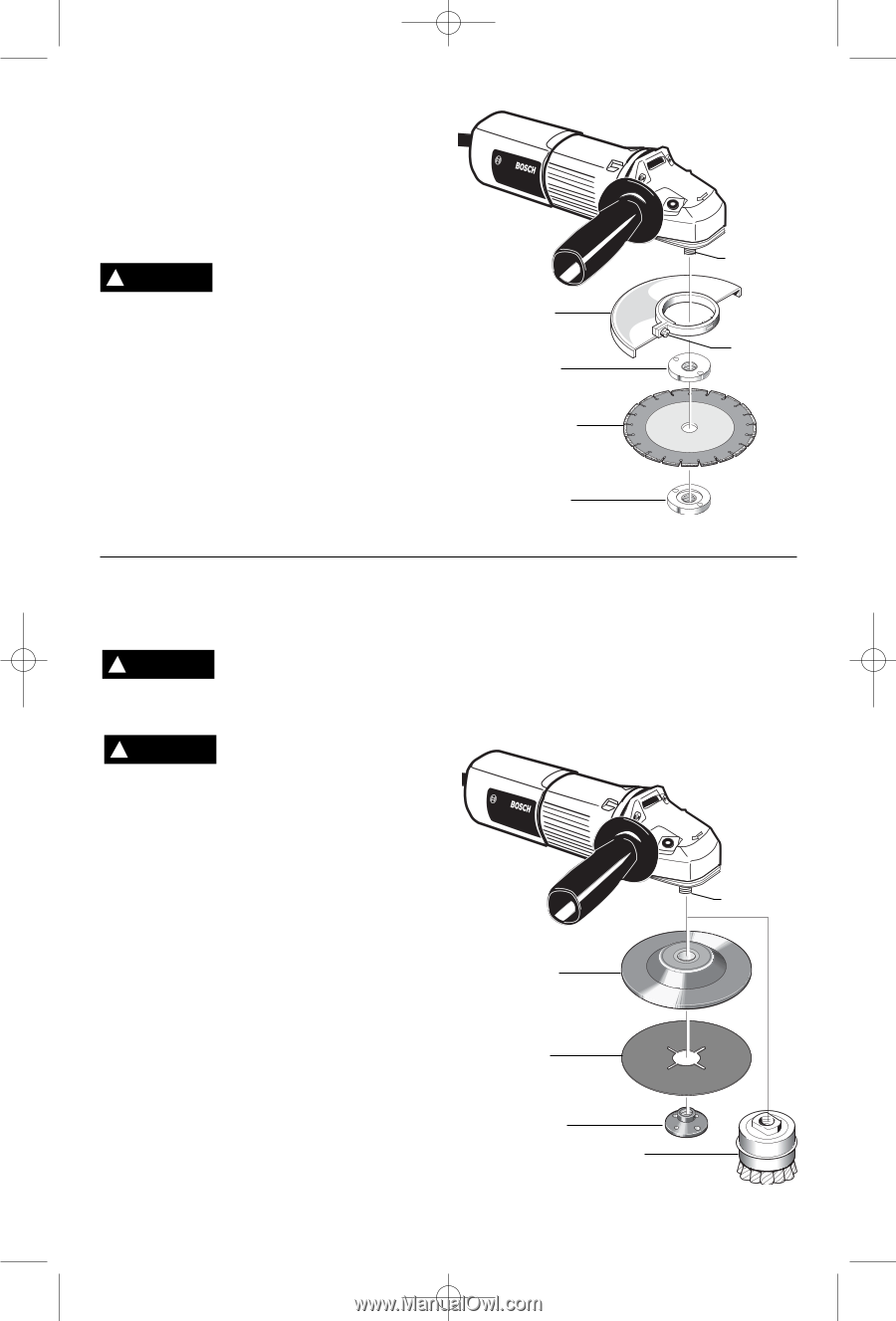

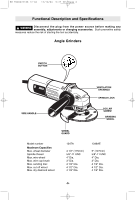

BM F000622188 12-04 12/10/04 9:27 PM Page 8 Masonry Cutting Wheel Assembly For cutting masonry materials like brick, tile, stone, etc., it is best to use a dry diamond cutting wheel. Use only lock nut and flange with equal diameters. The wheel guard must be used with a dry diamond cutting wheel. ! WARNING Do not use water or other cooling fluid with this tool for cutting. Disconnect tool from power source before attaching cutting wheel. With wheel guard in place, assemble flange, cutting wheel and lock nut as illustrated on page 7. When cutting, make only small passes through workpiece at a time. Be aware that "Kickback" can occur at any time. Keep both hands on tool for maximum control. WHEEL GUARD BACKING FLANGE DRY DIAMOND WHEEL LOCK NUT SPINDLE COLLAR SCREW Sanding Accessories Assembly BACKING PAD ! WARNING Before attaching a backing pad be sure its maximum safe operating speed is not exceeded by the nameplate speed of the tool. ! WARNING Wheel guard may not be used for most sanding operations. Always reinstall wheel guard when converting back to grinding operations. WIRE BRUSH ASSEMBLY Before assembling wire brush to this tool, disconnect from the power source. Wire brushes are equipped with their own threaded hub, simply thread on to spindle. Be sure to seat against shoulder before turning tool "ON". TO INSTALL BACKING PAD AND SANDING DISC Disconnect tool from power source. Set the tool on its top side (spindle up). Place the rubber backing pad onto the spindle shaft. Center the sanding disc on top of the backing pad. Insert the lock nut through the disc and thread onto the spindle as far as you can with your fingers. Press in the spindle lock, then tighten the backing pad securely with lock nut wrench. TO REMOVE BACKING PAD AND SANDING DISC Disconnect tool from power source. Using the lock nut wrench unscrew the nut from the spindle, while holding spindle lock in. BACKING PAD SANDING DISC LOCK NUT WIRE BRUSH SPINDLE -8-