Brother International EF4-B561 Service Manual - Page 32

Under, looper, harldy, enter., easily, Lower, under, contact, needle, deep., guard, adjust,

|

View all Brother International EF4-B561 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 32 highlights

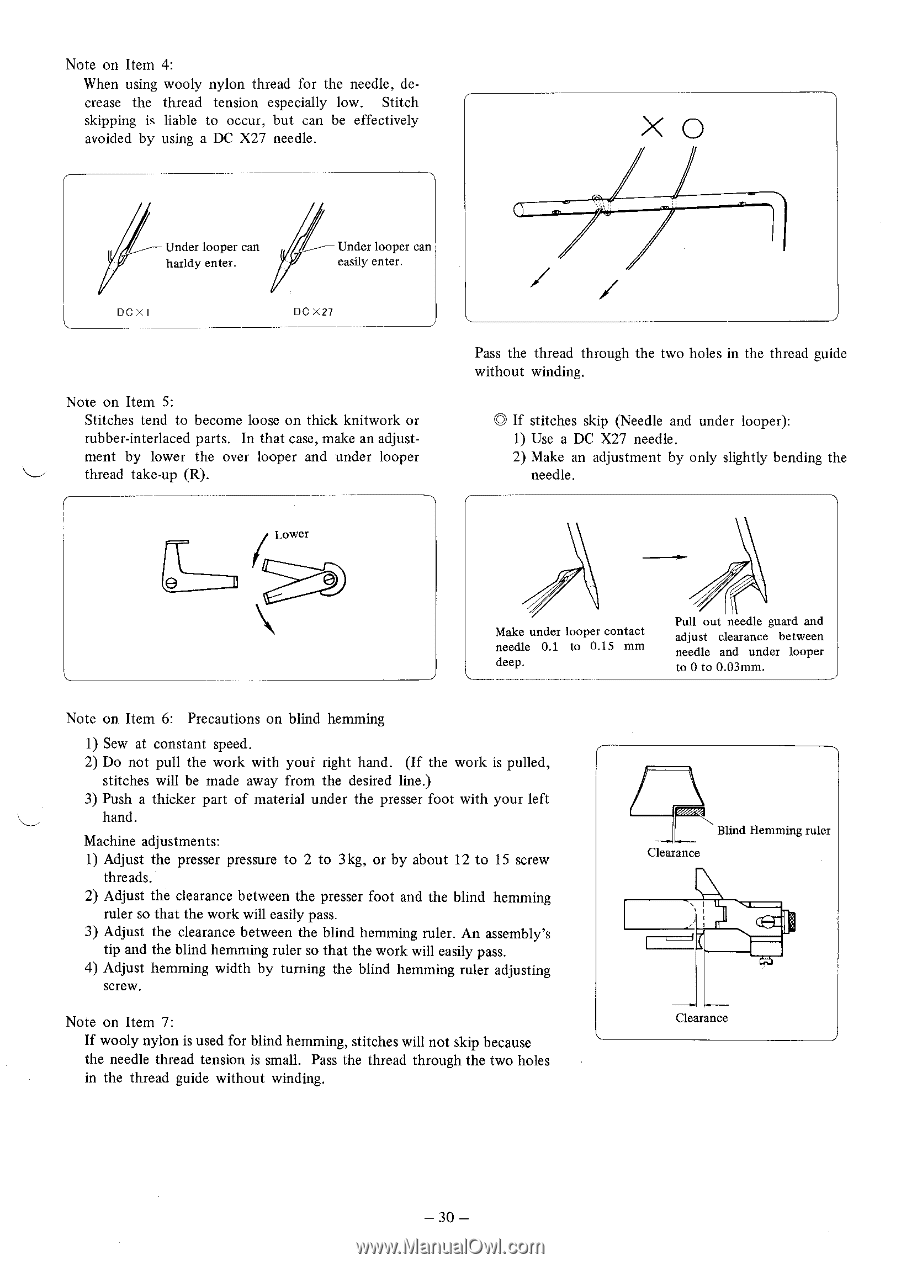

Note on Item 4: When using wooly nylon thread for the needle, decrease the thread tension especially low. Stitch skipping is liable to occur, but can be effectively avoided by using a DC X27 needle. x o /---- Under looper can harldy enter. Under looper can easily enter. DC/ I DC X27 Note on Item 5: Stitches tend to become loose on thick knitwork or rubber-interlaced parts. In that case, make an adjustment by lower the over looper and under looper thread take-up (R). Th I ( Lower 0 on Pass the thread through the two holes in the thread guide without winding. O If stitches skip (Needle and under looper): 1) Use a DC X27 needle. 2) Make an adjustment by only slightly bending the needle. Make under looper contact needle 0.1 to 0.15 mm deep. Pull out needle guard and adjust clearance between needle and under looper to 0 to 0.03mm. Note on Item 6: Precautions on blind hemming 1) Sew at constant speed. 2) Do not pull the work with your right hand. (If the work is pulled, stitches will be made away from the desired line.) 3) Push a thicker part of material under the presser foot with your left hand. Machine adjustments: 1) Adjust the presser pressure to 2 to 3kg, or by about 12 to 15 screw threads. 2) Adjust the clearance between the presser foot and the blind hemming ruler so that the work will easily pass. 3) Adjust the clearance between the blind hemming ruler. An assembly's tip and the blind hemming ruler so that the work will easily pass. 4) Adjust hemming width by turning the blind hemming ruler adjusting screw. Note on Item 7: If wooly nylon is used for blind hemming, stitches will not skip because the needle thread tension is small. Pass the thread through the two holes in the thread guide without winding. Blind Hemming ruler Clearance Clearance - 30 -