Brother International FB-N210 Instruction Manual - English and Spanish - Page 50

Troubleshooting, Caution

|

View all Brother International FB-N210 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 50 highlights

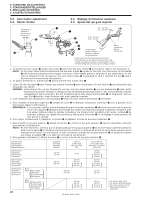

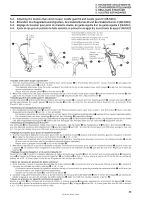

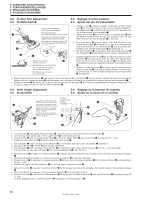

7. TROUBLESHOOTING 7. TROUBLESHOOTING CAUTION Turn off the power switch before carrying out troubleshooting, otherwise the machine will operate if the treadle is depressed by mistake, which could result in injury. * When using a clutch motor, the motor will keep turning even after the power is switched off as a result of the motor's inertia. Wait until the motor stops fully before starting work. Trouble What to check or do 1. Needle breaks. 2. Stitches skip. 3. Wrinkles appear. 4. Seams are not consistent. 5. Thread breaks. 6. Knives cut poorly. 7. Double chain stitching is not possible. 1. Use a needle and thread to match the material. 2. Check for proper needle installation. 3. Check the installation positions of the needle, under looper and over looper. 1. Check the installation positions of the needle, under looper and over looper. 2. Damaged or blunt looper tip: correct with sandpaper or install a new looper. 3. Check the thread tension. 4. Check the threading. 5. Check for low thread tension in the double chain stitch looper. 1. Use a needle and thread to match the material. 2. Check for high thread tension. 3. Check for high presser foot pressure. 4. Check the feed dog height. 5. Check the differential feed amount. 1. Inconsistent thread tension: check and clean the thread path. 2. Check for low thread tension. 3. Blunt needle tip: replace with a new needle. 4. Check for low presser foot pressure. 5. Check the feed dog height. 1. Check the needle installation. 2. Check the threading. 3. Check for high thread tension. 4. Check for damage to the looper, needle plate, needle, needle guard: fix with sandpaper or buffing. 1. Check the upper/lower knife overlap. 2. Check the upper/lower knife installation. 3. Check for upper/lower knife wear. 1. Check the threading. 2. Check the needle and looper thread tension. 3. Check the main feed dog height. 4. Check the presser foot position. 5. Check the double chain stitch looper installation. Reference page - 14 25 · 26 · 28 25 · 26 · 28 - 16 15 16 - 16 18 31 20 - 16 - 18 31 14 15 16 - 30 30 21 15 17 31 30 29 33 FB-N110, N210, N310 (English)