Brother International Innov-is 6700D Operation Manual for Premium Pack I Optio - Page 9

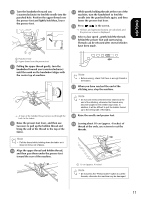

When tension is not applied to the bobbin, thread, handwheel aligns with the center top

|

View all Brother International Innov-is 6700D manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 9 highlights

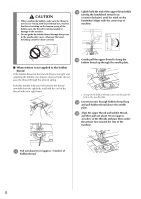

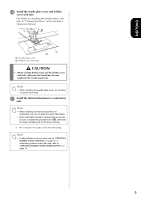

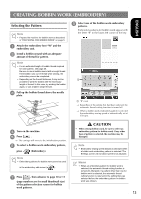

CAUTION • When winding the bobbin, make sure the thread is not frayed. Sewing with frayed thread may result in the thread catching on the tension spring of the bobbin case, the thread becoming tangled or damage to the machine. • Do not guide the bobbin thread through the groove in the needle plate cover, otherwise the lower threading cannot be done correctly. l Lightly hold the end of the upper thread while turning the handwheel toward you (counterclockwise) until the mark on the handwheel aligns with the center top of machine. ■ When tension is not applied to the bobbin thread If the bobbin thread in the trial stitching is too tight and adjusting the bobbin case tension does not help, do not pass the thread through the tension spring. Hold the bobbin with your left hand so the thread unwinds from the right side and hold the end of the thread with your right hand. m Gently pull the upper thread to bring the bobbin thread up through the needle plate. → A loop of the bobbin thread comes out through the hole in the needle plate. n Insert tweezers through bobbin thread loop and pull bobbin thread above the needle plate. o Align the upper thread and bobbin thread, and then pull out about 10 cm (approx. 4 inches) of the threads and pass them under the presser foot toward the rear of the machine. k Pull out about 8 cm (approx. 3 inches) of bobbin thread. 8