Brother International LK3-B432E MKII Instruction Manual - English - Page 68

TROUBLESHOOTING, Not applicable for the B432E Mark II., B432E Mark II only.

|

View all Brother International LK3-B432E MKII manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 68 highlights

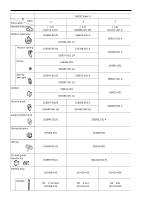

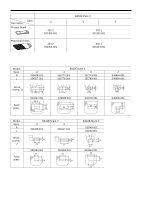

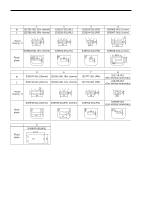

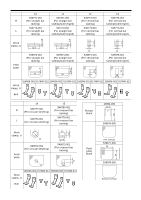

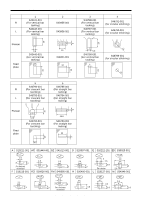

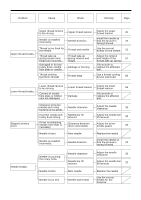

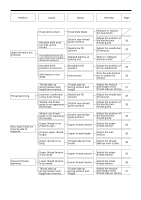

16. TROUBLESHOOTING Problem Cause Check 16. TROUBLESHOOTING Remedy Page *1 Work clamp operation is sluggish. Presser does not rise. Presser lifter amount is too great. *1 Too much friction between presser plate and presser arm lever support. Sliding part of the work clamp lubrication Distance between work clamp and top of needle plate Presser plate and presser arm lever support lubrication Grease the sliging part of the work 36 clamp. Adjust the height of the work clamp to within 17 mm. 36 • 37 Grease the presser plate and presser arm 36 lever support. Presser is contacting thread wiper. Thread wiper standby position Adjust the position of the thread wiper. 39 Presser does not drop. Presser lifter link is not moving back. Link return spring is unhooked. Hook the link return spring properly. Presser lift amount is incorrect. *2 Work clamp does not close. Incorrect position of presser arm lever plate. Incorrect position of presser closing roller. Distance between work clamp and top of needle plate Adjust the work clamp lift amount. 36 • 37 Whether stop lever is engaged with stop position adjustment bar or not Adjust the position of presser closing roller. 38 Thread wiper does not operate correctly. The thread wiper is obstructing the needle. Thread wiper position is incorrect. Clearance beween thread wiper and needle tip Thread wiper position Adjust the height of the thread wiper. 39 Adjust the operating distance of the thread 39 wiper. Lower thread winds to one side. Bobbin winder thread tension stud height is incorrect. Bobbin winder thread tension stud height Adjust the height of the thread tension stud. 24 Lower thread winding amount is incorrect. Bobbin presser position is incorrect. Thread winding amount Adjust the position of the bobbin presser. 24 Stitches being skipped at the sewing start. Refer to "Skipped stitches occur" Refer to "Skipped stitches occer". Threads comes unthreaded. Uneven upper thread length. Upper thread length Adjust the subtension. 26 Upper thread is too short. Thread take-up lever stroke Adjust the thread take-up lever stroke. 34 * 1 Not applicable for the B432E Mark II. * 2 B432E Mark II only. LK3-B430E-, B431E-, B432E-, B433E- Mark II 62