Brother International LS-2125i Users Manual - English - Page 51

Bobbin tension is too tight

|

UPC - 012502615293

View all Brother International LS-2125i manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 51 highlights

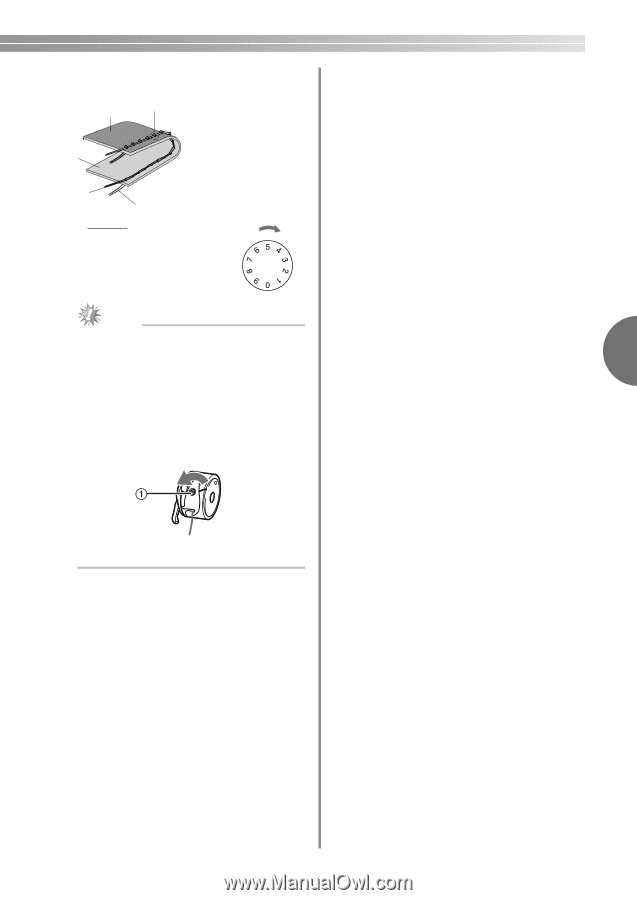

■ Bobbin tension is too tight Loops appear on the wrong side of the fabric. 1 5 2 3 4 a Wrong side b Surface c Upper thread d Lower thread e Loops appear on wrong side of fabric Solution Increase the tension by turning the upper tension- control dial to a higher number. Note ● If the loops still appear on the wrong side of the fabric after you adjust the upper tension, 4 the bobbin thread may be too tight. In this case, turn the screw counterclockwise being careful not to over-loosen the screw, approximately 30-45 degrees to decrease bobbin tension. After you adjust the bobbin thread, adjust the upper thread to match the bobbin thread. a Screw 49

49

4

■

Bobbin tension is too tight

Loops appear on the wrong side of the fabric.

Solution

Increase the tension by

turning the upper tension-

control dial to a higher

number.

Note

●

If the loops still appear on the wrong side of

the fabric after you adjust the upper tension,

the bobbin thread may be too tight. In this

case, turn the screw counterclockwise being

careful not to over-loosen the screw,

approximately 30-45 degrees to decrease

bobbin tension. After you adjust the bobbin

thread, adjust the upper thread to match the

bobbin thread.

a

Screw

1

2

3

4

5

a

Wrong side

b

Surface

c

Upper thread

d

Lower thread

e

Loops appear on

wrong side of

fabric