Brother International MD-817 Service Manual - Page 5

Features

|

View all Brother International MD-817 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 5 highlights

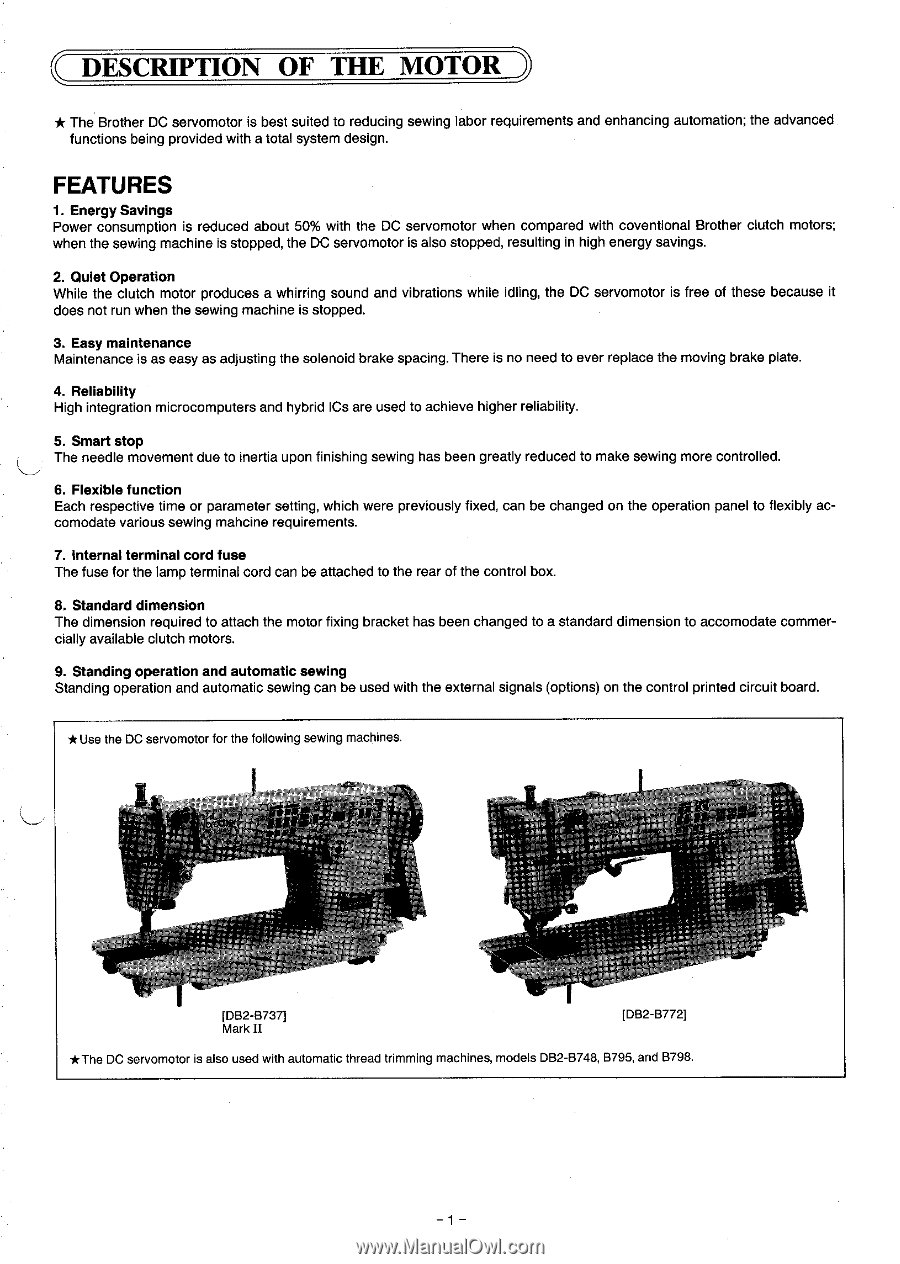

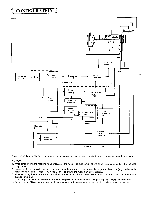

C DESCRIPTION OF THE MOTOR * The Brother DC servomotor is best suited to reducing sewing labor requirements and enhancing automation; the advanced functions being provided with a total system design. FEATURES 1. Energy Savings Power consumption is reduced about 50% with the DC servomotor when compared with coventional Brother clutch motors; when the sewing machine is stopped, the DC servomotor is also stopped, resulting in high energy savings. 2. Quiet Operation While the clutch motor produces a whirring sound and vibrations while idling, the DC servomotor is free of these because it does not run when the sewing machine is stopped. 3. Easy maintenance Maintenance is as easy as adjusting the solenoid brake spacing. There is no need to ever replace the moving brake plate. 4. Reliability High integration microcomputers and hybrid Cs are used to achieve higher reliability. 5. Smart stop The needle movement due to inertia upon finishing sewing has been greatly reduced to make sewing more controlled. 6. Flexible function Each respective time or parameter setting, which were previously fixed, can be changed on the operation panel to flexibly accomodate various sewing mahcine requirements. 7. Internal terminal cord fuse The fuse for the lamp terminal cord can be attached to the rear of the control box. 8. Standard dimension The dimension required to attach the motor fixing bracket has been changed to a standard dimension to accomodate commercially available clutch motors. 9. Standing operation and automatic sewing Standing operation and automatic sewing can be used with the external signals (options) on the control printed circuit board. * Use the DC servomotor for the following sewing machines. [D82-8737] Mark II [DB2-B7721 *The DC servomotor is also used with automatic thread trimming machines, models DB2-6748, 8795, and 8798.