Craftsman 21609 Operation Manual - Page 8

Wire Size A.W.G.

|

View all Craftsman 21609 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 8 highlights

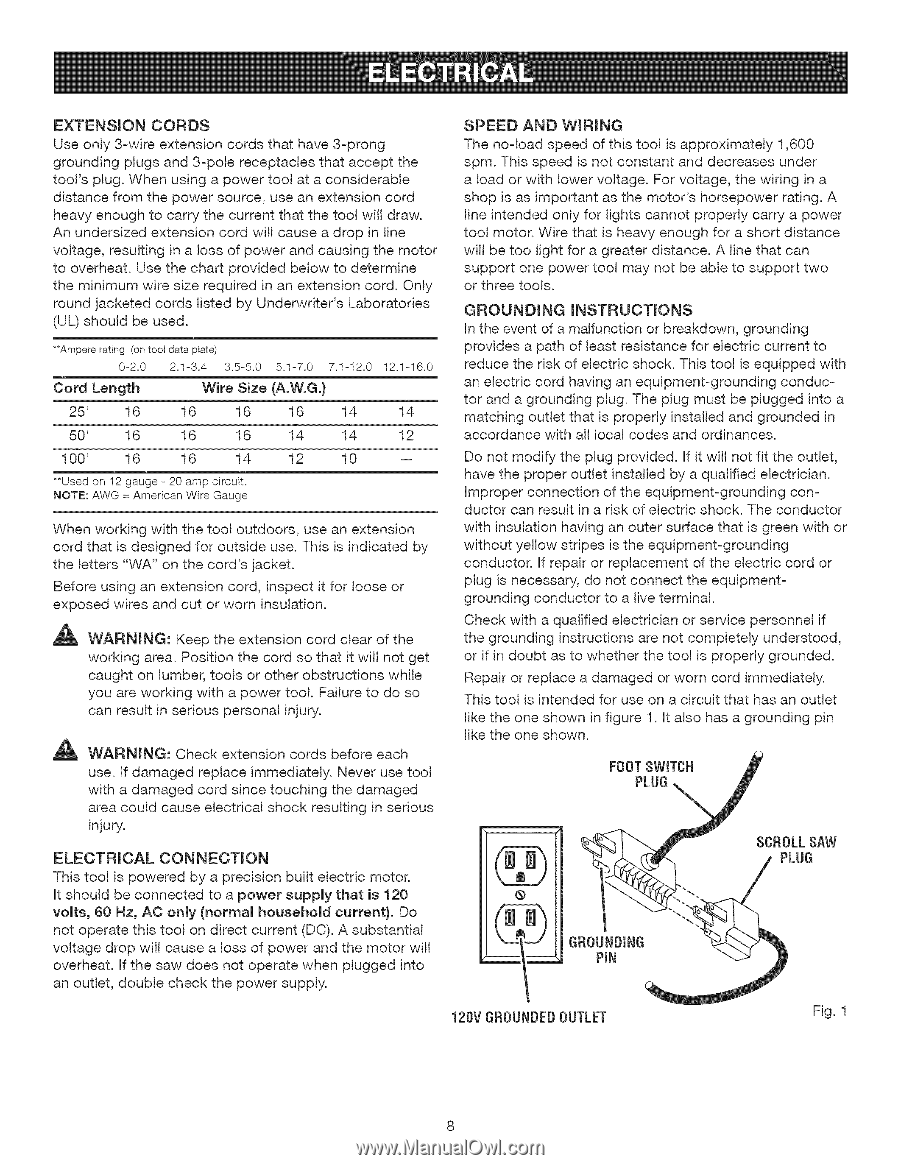

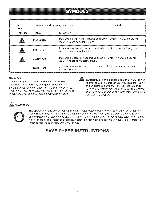

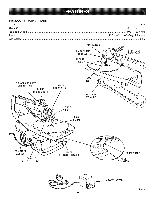

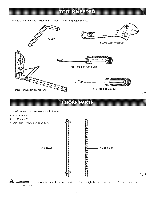

EXTENSION CORDS Use only 3=wire extension cords that have 3=prong grounding plugs and 3-pole receptacles that accept the tool's plug. When using a power tool at a considerable distance from the power source, use an extension cord heavy enough to carry the current that the tool will draw. An undersized extension cord wil! cause a drop in line voltage, resulting in a loss of power and causing the motor to overheat. Use the chart provided below to determine the minimum wire size required in an extension cord. Only round jacketed cords listed by Underwdter's Laboratories (UL) should be used. **Ampere rating (on tool data p_ate) 0-2.0 2.1-3.4 3.5-5.0 5.1-7.0 7.1-12.0 Cord Length 25' 16 Wire Size (A.W.G.) 16 16 16 14 12.1-16.0 14 50' 16 16 16 14 14 12 100' 16 16 14 12 10 -- **Used on 12 gauge - 20 amp circuit NOTE: AWG = American Wire Gauge When working with the tool outdoors, use an extension cord that is designed for outside use. This is indicated by the letters "WA" on the cord's jacket. Before using an extension cord, inspect it for loose or exposed wires and cut or worn insulation. _ WARNING: Keep the extension cord clear of the working area. Position the cord so that it wil! not get caught on lumber, tools or other obstructions while you are working with a power tool. Failure to do so can result in serious personal injury. A WARNING: Check extension cords before each use. If damaged replace immediately. Never use tool with a damaged cord since touching the damaged area could cause electrical shock resulting in serious injury. ELECTRICAL CONNECTmON This tool is powered by a precision built electric motor. It should be connected to a power supply that is 120 volts, 60 Hz, AC only (normal household current}° Do not operate this tool on direct current (DC). A substantial voltage drop will cause a loss of power and the motor wilt overheat. If the saw does not operate when plugged into an outlet, double check the power supply. SPEED AND WRING The no=load speed of this too! is approximately 1,600 spm. This speed is not constant and decreases under a load or with lower voltage. For voltage, the wiring in a shop is as important as the motor's horsepower rating. A line intended only for lights cannot properly carry a power tool motor. Wire that is heavy enough for a short distance win be too light for a greater distance. A line that can support one power tool may not be able to support two or three tools. GROUNDING INSTRUCTIONS In the event of a malfunction or breakdown, grounding provides a path of least resistance for electric current to reduce the risk of electric shock, This tool is equipped with an electric cord having an equipment=grounding conduc= tot and a grounding plug, The plug must be plugged into a matching outlet that is properly installed and grounded in accordance with all local codes and ordinances, Do not modify the plug provided, If it will not fit the outlet, have the proper outlet installed by a qualified electrician, Improper connection of the equipment-grounding conductor can result in a risk of electric shock, The conductor with insulation having an outer surface that is green with or without yellow stripes is the equipment-grounding conductor, If repair or replacement of the electric cord or plug is necessary, do not connect the equipmentgrounding conductor to a live terminal, Check with a qualified electrician or service personnel if the grounding instructions are not completely understood, or if in doubt as to whether the tool is properly grounded, Repair or replace a damaged or worn cord immediately, This toot is intended for use on a circuit that has an outlet like the one shown in figure 1, It also has a grounding pin like the one shown, FOOTSWtTCN PLUG SOROLLSAW PLUG ® 120V GROUNDED OUTLET Fig. 1