Dell PowerEdge PDU Metered LCD Best Practices Guide for Rack Enclosures - Page 7

Rack Installation

|

View all Dell PowerEdge PDU Metered LCD manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 7 highlights

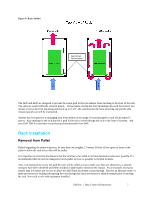

Figure 4: Rack Airflow Gap Allows Recirculation The 2420 and 4220 are designed to prevent the return path for hot air exhaust from traveling to the front of the rack. The sides are sealed with side closeout panels. These panels overlap the front mounting rails such that even if you choose to move the front mounting rails back up to 2-1/4", the seal between the front mounting rail and the side closeout panels can still be maintained. Another key best practice in managing rack level airflow is the usage of closeout panels to seal off all empty Uspaces. Any openings in the rack provide a path for hot air to travel through the rack to the front of systems. Ask your Dell TSR for assistance in purchasing closeout panels from Dell. Rack Installation Removal from Pallet Before beginning the removal process, be sure there are roughly 2.7 meters (9 feet) of free space in front of the pallet to allow the rack to be rolled off the pallet. It is important to minimize the distance that the rack has to be rolled to its final destination whenever possible. It's recommended that the rack be transported on its pallet as close as possible to its final location. Also, it is important to survey the path the rack will be rolled across to make sure that any obstacles to a smooth transport have been identified and either avoided or addressed to minimize the impact. As an example, doorways shorter than 2.0 meters are too low to allow the 4220 Rack Enclosure to pass through. Plan for an alternate route, or make provisions for dealing with getting the rack through any short doorway in a suitable manner prior to moving the rack. Never tilt a rack with equipment installed. Dell Inc. | Data Center Infrastructure 7