Dewalt DC618K Instruction Manual - Page 8

Clearing a Jammed Nail Fig. 11

|

View all Dewalt DC618K manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 8 highlights

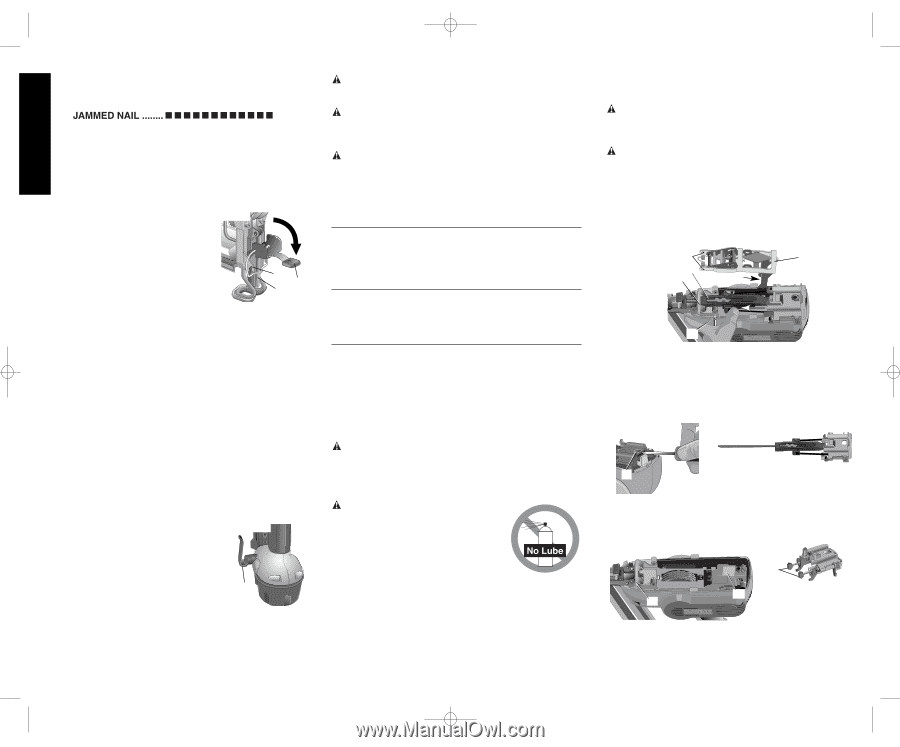

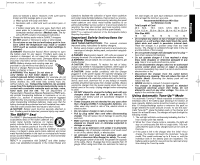

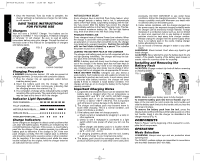

644429-00,DC612 7/10/06 11:56 AM Page 6 English JAMMED NAIL INDICATOR: The headlights will flash continually if a nail becomes jammed in the nosepiece (see Clearing a Jammed Nail). Clearing a Jammed Nail (Fig. 11) If a nail becomes jammed in the nosepiece, keep the tool pointed away from you and follow these instructions to clear: 1. Remove battery pack from tool and engage contact trip lock-off. 2. Pull the pusher back until it locks in place then remove the nails. 3. Lift the jam clearing latch (E) then FIG. 11 pull up to open front door (O). 4. Remove bent nail, using pliers if necessary. 5. If driver blade is in the down position, insert screwdriver or other rod into nosepiece and push driver blade back in position. 6. Close the front door and engage N E O the wireform under the 2 arms (N) on the nosepiece. Push latch until it locks in place. 7. Reinsert battery pack. NOTE: The tool will disable itself and not reset until the battery pack has been removed and reinserted. 8. Reinsert nails into magazine (see Loading the Tool). 9. Release pusher. NOTE: Should nails continue to jam frequently in nosepiece, have tool serviced by an authorized DEWALT service center. Cold Weather Operation When operating tools at temperatures below freezing: 1. Keep tool as warm as possible prior to use. 2. Actuate the tool 5 or 6 times into scrap lumber before using. Hot Weather Operation Tool should operate normally. However, keep tool out of direct sunlight as excessive heat can deteriorate bumpers and other rubber parts resulting in increased maintenance. Suspension Hook (Fig. 12) FIG. 12 The DEWALT cordless nailers include an integrated suspension hook (J) and can be attached to either side of the tool to accom- modate left- or right-handed users. If the hook is not desired at all, it can be removed from the tool. J TO REMOVE SUSPENSION HOOK 1. Remove battery pack from tool. 2. To switch the tool from right- to left-hand usage simply remove the screw from the opposite side of the tool and reassemble on the other side. 3. Replace battery pack. WARNING: Remove nails from magazine before making any adjustments or servicing this tool. Failure to do so may result in serious injury. CAUTION: Disconnect battery pack from tool before making any adjustments, changing accessories, servicing, or moving the tool. Such preventative safety measures reduce the risk of starting the tool accidentally. CAUTION: When not in use, place tool on its side on a stable surface where it will not cause a tripping or falling hazard. Some tools with large battery packs will stand upright on the battery pack but may be easily knocked over. MAINTENANCE Daily Maintenance Chart ACTION Clean magazine, pusher, and contact trip mechanism. WHY Permits smooth operation of magazine, reduces wear, and prevents jams. HOW Blow clean with compressor air. The use of oils, lubricants periodically or solvents is not recommended as they tend to attract debris. ACTION Before each use, check to insure all screws, nuts and fasteners are tight and undamaged. WHY Prevents jams and premature failure of tool parts. HOW Tighten loose screws or other fasteners using the appropriate allen wrench or screwdriver. Cleaning Use only mild soap and a damp cloth to clean the tool. Many household cleaners contain chemicals which could seriously damage plastic. Also, do not use gasoline, turpentine, lacquer or paint thinner, dry cleaning fluids or similar products. Never let any liquid get inside the tool; never immerse any part of the tool into a liquid. CHARGER CLEANING INSTRUCTIONS WARNING: Disconnect the charger from the AC outlet before cleaning. Dirt and grease may be removed from the exterior of the charger using a cloth or soft non-metallic brush. Do not use water or any cleaning solutions. Lubrication CAUTION: NEVER spray or in any other way apply lubricants or cleaning solvents inside the tool. This can seriously affect the life and performance of the tool. DEWALT tools are properly lubricated at the factory and are ready for use. However, it is recommended that, once a year, you take or send the tool to a certified service center for a thorough cleaning and inspection. Repairs To assure product SAFETY and RELIABILITY, repairs, maintenance and adjustment (including brush inspection and replacement) should be performed by a DEWALT factory 6 service center, a DEWALT authorized service center or other qualified service personnel. Always use identical replacement parts. CAUTION: Disconnect battery pack from tool before making any adjustments, changing accessories, servicing, or moving the tool. Such preventative safety measures reduce the risk of starting the tool accidentally. CAUTION: Remove nails from magazine before making any adjustments or servicing this tool. Failure to do so may result in serious injury. TO SERVICE 1. Remove 3 T25 slotted screws from top cover. Remove cover from housing and set aside. 2. Using a nail or punch, apply pressure to the pin (Q) sliding the pin out from the metal structure (Fig. 13). FIG. 13 W S R V U Q 3. Push driver/return assembly (R) toward nosepiece and hold in place against the lower bumper (V) as you roll back the activation arm Assembly (S). Remove activation arm assembly and set aside. 4. Use a flat blade screwdriver to pry up on the return cord assembly (T) until the detents release. Lift up to remove (Fig. 14). FIG. 14 FIG. 15 T DRIVER/RETURN ASSEMBLY Available by calling 1-800-4-DEWALT 5. Remove the driver/return assembly (Fig. 15). 6. Inspect lower bumper (V), upper bumper (X), and other surfaces for cracks or damage and replace if necessary (Fig. 16). Replace damaged return cord assembly. FIG. 16 FIG. 17 Y RETURN CORD X ASSEMBLY V Available by calling 1-800-4-DEWALT TO REPLACE RETURN CORD ASSEMBLY NOTE: For correct cord position during assembly, refer to the proper orientation of the return cord assembly in Figure 15.