Dewalt DWE4517 Instruction Manual - Page 11

ASSEMBLY AND ADJUSTMENTS, Attaching the Side Handle Fig. 3, Rotating the Gear Case, Fig. 4, - service center

|

View all Dewalt DWE4517 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 11 highlights

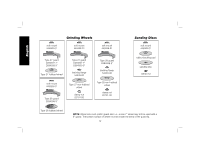

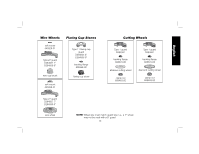

English accessories running over rated speed can fly apart and cause injury. Accessory ratings must always be above tool speed as shown on tool nameplate. ATTACHMENTS Attachments designed specifically for this grinder can be purchased through DEWALT dealers and DEWALT Factory Service centers. 9" Type 27 guard D284939 9" Type 28 guard D284938 7" Type 27 guard D284937 6" Type 11 Flaring cup guard with flange D284936 4" Type 11 Flaring cup guard with flange D284934 Type 11 Flaring cup wheel backing flange 608368-00 Type 1 Flange set D284932 7" Type 1 Guard D284931 Grinding backing flange 54339-00 Clamp nut 22191-00 Wheel Wrench 61820-01 Soft mount spindle protector 445928-01 ASSEMBLY AND ADJUSTMENTS WARNING: To reduce the risk of injury, turn unit off and disconnect it from power source before installing and removing accessories, before adjusting or when making repairs. An accidental start-up can cause injury. Attaching the Side Handle (Fig. 3) Attach the side handle (C) to one of the two FIG. 3 C side handle ports (H). Rotating the Gear Case (Fig. 4) H 1. Remove guard and flanges from FIG. 4 tool. 2. Remove the four corner screws attaching the gear case to motor housing. 3. Separate the gear case from motor housing, not more than 1/4" (6.35 mm), rotate the gear case head to desired position. NOTE: If the gear case and motor housing become separated by more than 1/4" (6.35 mm), the tool must be serviced and re-assembled by a DEWALT service center. Failure to have the tool serviced may cause brush, motor and bearing failure. 4. Re-install screws to attach the gear case to the motor housing. Tighten screws to 20 in./lbs. torque. Overtightening could cause screws to strip. OPERATION WARNING: To reduce the risk of injury, turn unit off and disconnect it from power source before installing and removing accessories, before adjusting or when making repairs. An accidental start-up can cause injury. 9