Dewalt DWE4517 Instruction Manual - Page 12

Power Source, Switch Fig. 5, Mounting and Using Depressed Center, Grinding Wheels and Sanding Flap - accessories

|

View all Dewalt DWE4517 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 12 highlights

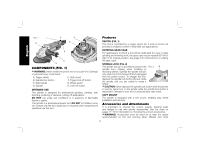

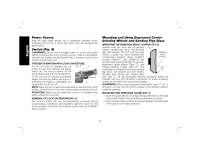

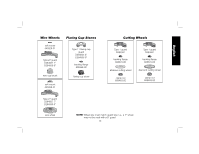

English Power Source Plug the large angle grinder into a dedicated electrical circuit. Operating this tool on a circuit with other tools will decrease tool performance. Switch (Fig. 5) WARNING: Ensure that the trigger switch is in the off position before connecting the tool to a power source or after a power failure. Hold the side handle and rear handle firmly to maintain control of tool at start up and during use. TRIGGER OPERATION WITH LOCK-ON FEATURE To turn the tool on, depress lock off FIG. 5 F button (F) and then depress the trigger switch (A). The lock-on button (H) will remain depressed and tool will remain on. To turn the tool off, depress and release A trigger. The lock pin button will pop out, permitting the trigger to disengage and H causing the tool to turn off. NOTE: Allow the tool to reach full speed before touching tool to work surface. Lift the tool from the work surface before turning the tool off. CAUTION: Make sure the wheel has come to a complete stop before setting the tool down. REMOVAL OF LOCK-ON FEATURE (FIG. 1) The lock-on button (H) can be permanently removed without compromising compliance with regulatory agencies shown on the tool's nameplate. Removal of the lock pin must be done by a DEWALT Service Center. Mounting and Using Depressed Center Grinding Wheels and Sanding Flap Discs IMPORTANT INFORMATION ABOUT GUARDS (FIG. 6) Guards must be used with all grinding FIG. 6 wheels, sanding flap discs, wire brushes and wire wheels. The tool may be used GRINDING without a guard only when sanding with conventional sanding discs. DEWALT WHEEL SURFACE models DWE4517 and DWE4519 are provided with a guard intended for use with depressed center wheels (Type 27), and hubbed grinding wheels (Type 27). The GUARD same guard is designed for use with sanding LIP flap discs, wire brushes and wire wheels. Grinding and cutting with wheels other than Type 27, 28 and 29 require different accessory guards not included with the tool. Mounting instructions for these accessory guards are included in the accessory package. WARNING: When using a grinding wheel with a Type 27, 28, or 29 guard, be sure that the bottom surface of the grinding wheel is inside the guard lip. MOUNTING AND REMOVING GUARD (FIG. 7) 1. Open the guard latch (I), and align the lugs with slots on the gear case cover. Position the guard facing backward, as shown. 2. Push the guard down until the guard lugs engage and rotate freely in the groove on the gear case hub. 10