E-Z-GO Express L6 - Gas Owner Manual - Page 70

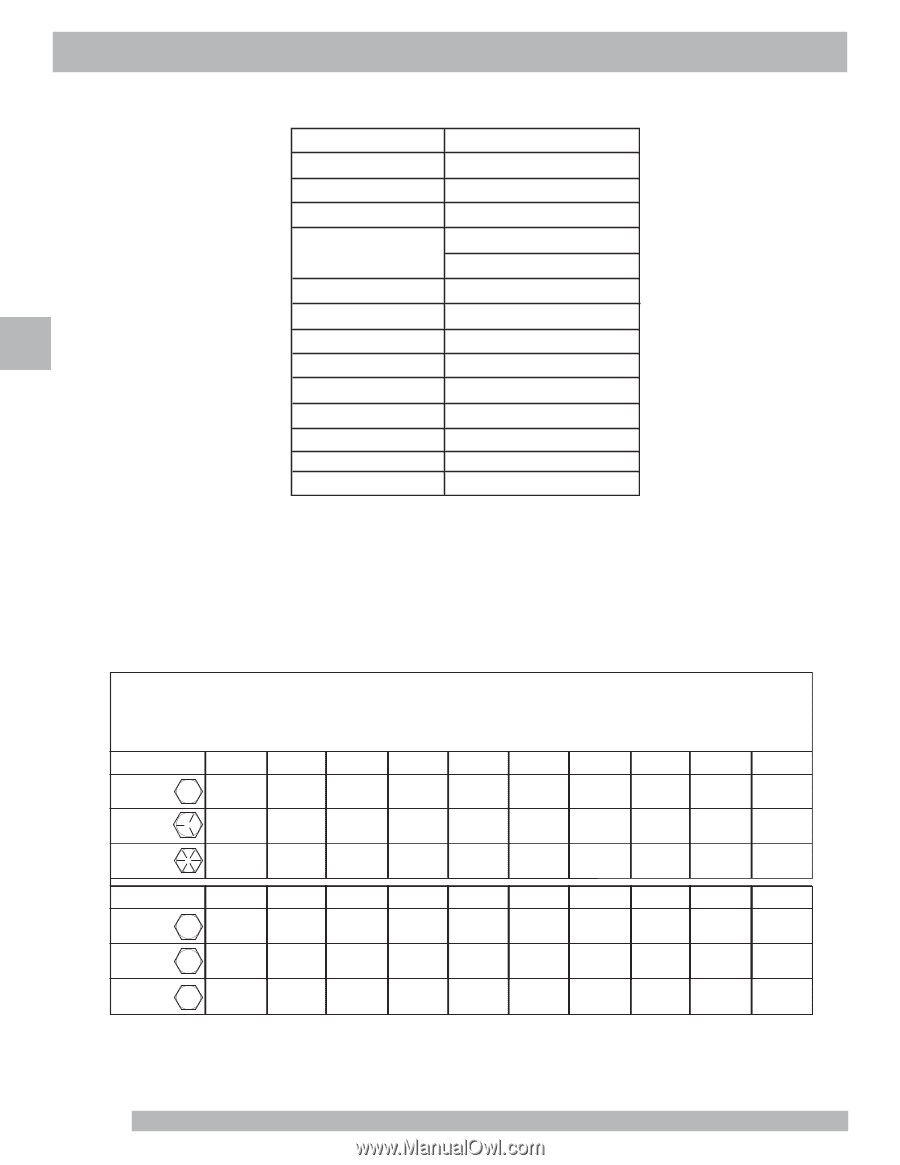

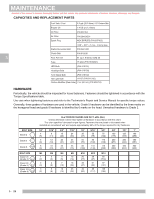

CAPACITIES AND REPLACEMENT PARTS, HARDWARE, Torque Specifications table.

|

View all E-Z-GO Express L6 - Gas manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 70 highlights

MAINTENANCE Read all of this manual to become thoroughly familiar with this vehicle. Pay particular attention to all Notices, Cautions, Warnings, and Dangers. CAPACITIES AND REPLACEMENT PARTS Fuel Tank / Fuel 5.3 gal (20.0 liters) / 87 Octane Min Engine Oil 1.4 US qt (1.3 liters) Oil Filter P/N 607454 Air Filter Spark Plug P/N 28463G01 NGK BPR2ES (P/N 607462) Starter/Generator Belt .028" - .031" (.7 mm - .8 mm) Gap P/N 26414G1 Clutch Belt P/N 618630 5 Rear Axle Oil 51 oz (1.5 liters) / SAE 30 Fuse 15 amp (P/N 18392G1) LED Bulb (P/N 619101) Headlight Bulb (P/N 619100) Turn Signal Bulb (P/N 619102) Tail Light Bulb #1157 (P/N 611242) Friction Modifier (Rear Axle) 2 oz (60 mL) (P/N 625753) HARDWARE Periodically, the vehicle should be inspected for loose fasteners. Fasteners should be tightened in accordance with the Torque Specifications table. Use care when tightening fasteners and refer to the Technician's Repair and Service Manual for specific torque values. Generally, three grades of hardware are used in the vehicle. Grade 5 hardware can be identified by the three marks on the hexagonal head and grade 8 hardware is identified by 6 marks on the head. Unmarked hardware is Grade 2. BOLT SIZE Grade 2 Grade 5 Grade 8 BOLT SIZE Class 5.8 (Grade 2) 5.8 Class 8.8 (Grade 5) 8.8 Class 10.9 (Grade 8) 10.9 ALL TORQUE FIGURES ARE IN FT. LBS. (Nm) Unless otherwise noted in text, tighten all hardware in accordance with this chart. This chart specifies 'lubricated' torque figures. Fasteners that are plated or lubricated when installed are considered 'wet' and require approximately 80% of the torque required for 'dry' fasteners. 1/4" 5/16" 3/8" 7/16" 1/2" 9/16" 5/8" 3/4" 7/8" 1" 4 8 15 24 35 55 75 130 125 190 (5) (11) (20) (33) (47) (75) (102) (176) (169) (258) 6 13 23 35 55 80 110 200 320 480 (8) (18) (31) (47) (75) (108) (149) (271) (434) (651) 6 18 35 55 80 110 170 280 460 680 (8) (24) (47) (75) (108) (149) (230) (380) (624) (922) M4 M5 M6 M8 M10 M12 M14 1 2 4 10 20 35 55 (2) (3) (6) (14) (27) (47) (76.4) 2 4 7 18 35 61 97 (3) (6) (10) (24) (47) (83) (131) 3 6 10 25 49 86 136 (4) (8) (14) (34) (66) (117) (184) 5 - 26