E-Z-GO Express S4 - Electric Owner Manual - Page 62

LUBRICATION, Hardware

|

View all E-Z-GO Express S4 - Electric manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 62 highlights

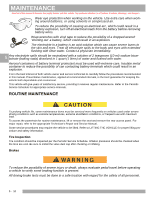

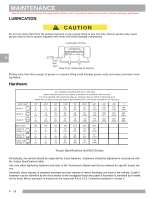

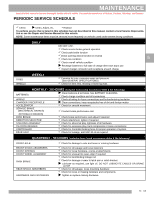

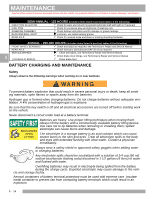

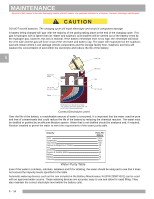

MAINTENANCE Read all of this manual to become thoroughly familiar with this vehicle. Pay particular attention to all Notices, Cautions, Warnings, and Dangers. LUBRICATION Do not use more than three (3) pumps of grease in any grease fitting at any one time. Excess grease may cause grease seals to fail or grease migration into areas that could damage components. Lubrication Points 5 Rack Ball Joint View from Underside of Vehicle Putting more than three pumps of grease in a grease fitting could damage grease seals and cause premature bearing failure. Hardware BOLT SIZE Grade 2 Grade 5 Grade 8 BOLT SIZE Class 5.8 (Grade 2) 5.8 Class 8.8 (Grade 5) 8.8 Class 10.9 (Grade 8) 10.9 ALL TORQUE FIGURES ARE IN FT. LBS. (Nm) Unless otherwise noted in text, tighten all hardware in accordance with this chart. This chart specifies 'lubricated' torque figures. Fasteners that are plated or lubricated when installed are considered 'wet' and require approximately 80% of the torque required for 'dry' fasteners. 1/4" 5/16" 3/8" 7/16" 1/2" 9/16" 5/8" 3/4" 7/8" 1" 4 8 15 24 35 55 75 130 125 190 (5) (11) (20) (33) (47) (75) (102) (176) (169) (258) 6 13 23 35 55 80 110 200 320 480 (8) (18) (31) (47) (75) (108) (149) (271) (434) (651) 6 18 35 55 80 110 170 280 460 680 (8) (24) (47) (75) (108) (149) (230) (380) (624) (922) M4 M5 M6 M8 M10 M12 M14 1 2 4 10 20 35 55 (2) (3) (6) (14) (27) (47) (76.4) 2 4 7 18 35 61 97 (3) (6) (10) (24) (47) (83) (131) 3 6 10 25 49 86 136 (4) (8) (14) (34) (66) (117) (184) Torque Specifications and Bolt Grades Periodically, the vehicle should be inspected for loose fasteners. Fasteners should be tightened in accordance with the Torque Specifications table. Use care when tightening fasteners and refer to the Technician's Repair and Service Manual for specific torque values. Generally, three classes of standard hardware and two classes of metric hardware are used in the vehicle. Grade 5 hardware can be identified by the three marks on the hexagonal head and grade 8 hardware is identified by 6 marks on the head. Metric hardware is marked on the head with 8.8 or 10.9. Unmarked hardware is Grade 2. 5 - 12