HP LaserJet Enterprise MFP M630 Print Media Guide - Page 37

Envelope problems, Frequent envelope jams, Gray areas on envelopes

|

View all HP LaserJet Enterprise MFP M630 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 37 highlights

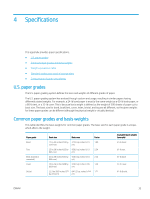

Envelope problems Certain conditions can indicate envelope problems, such as high rates of jams, gray areas printing on envelopes, and wrinkling. ● Frequent envelope jams ● Gray areas on envelopes ● Wrinkles on envelopes Frequent envelope jams Frequent envelope jams can have several possible causes and can be corrected by following the suggested actions. Overfilling the envelope tray and misadjusting its guides are the most common causes of jams. However, if the envelope tray is properly loaded, the envelopes might be causing the problems. To recover from an envelope jam, follow the directions provided in the HP LaserJet printer user guide. CAUTION: Do not reuse jammed envelopes. Doing so can damage the printer. Table 3-4 Frequent envelope jams: causes and corrective actions Cause Actions Envelopes are poorly manufactured. ● Make sure that the leading edge is straight, and has a sharp, well-creased fold. The envelope must not have more than two thicknesses of paper along any leading edge. The folded layers of paper should come to a point at the leading-edge corners. (See the figure in Envelope construction on page 14.) ● Purchase envelopes that are manufactured correctly, or run the side of a pen or pencil over the envelope edges to flatten them. Envelopes are not creased sufficiently to have sharp edges. Crease the leading edge of the envelope with the side of a pen or pencil, or change to a different type or brand. Envelopes are wrinkled, bent, or curled. Make sure that the envelope's leading edge, which enters the printer first, is straight, and that it has a sharp, well-creased fold that has no more than two thicknesses of paper. Envelopes are too stiff or heavy. Stiff or heavy envelopes cannot negotiate the paper path or be picked up from the envelope tray. ● Use a lighter-weight envelope. Do not exceed the basis weight of 105 g/m2 (28 lb). ● Use the printer's most direct (straight-through) paper path. Envelopes are too smooth (do not have enough friction for transport) or too rough. Change to a different type of envelope. Envelopes are jamming on the flap because the flap is at the pick roller contact point. Feed the envelope so that it is not flap first. Gray areas on envelopes Gray areas on envelopes have some possible causes and can be corrected by following the suggested actions. ENWW Envelope problems 31