HP Scitex FB6100 Printing Technologies - Page 12

HP Scitex WB300 Supreme Inks

|

View all HP Scitex FB6100 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 12 highlights

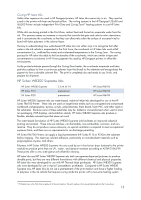

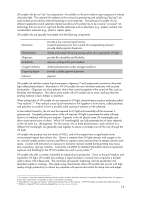

Curing HP Latex Inks Unlike other aqueous inks used in HP Designjet printers, HP Latex Inks cannot dry in air. They must be cured in the printer with heat and forced airflow. The writing systems in the HP Designjet L25500 and L65500 Printer include independent Print Zone and Curing Zone32 heating systems to cure HP Latex Inks. While dots are being printed in the Print Zone, radiant heat and forced air evaporate water from the ink. This process causes an increase in viscosity that controls dot gain and color-to-color interactions, and it concentrates the co-solvents so that they can effectively soften the surface of uncoated vinyl to bond with latex polymers in the colorant layer. The key to understanding how water-based HP Latex Inks can soften vinyl is to recognize that after water in the ink vehicle is evaporated in the Print Zone, the co-solvents in HP Latex Inks work at full concentration (i.e., undiluted by water) and at elevated temperatures in the Curing Zone. The curing process for HP Latex Inks adds to the functionality of the co-solvents, which are similar in type and concentration to co-solvents in HP Vivera pigment inks used by HP Designjet printers in office-like environments. As the printed substrate passes through the Curing Zone heater, the co-solvents evaporate and latex particles coalesce to form a continuous polymer layer that bonds to the substrate and encapsulates the pigment to form a durable colorant film. The print is completely dry and ready to use, finish, and prepare for shipment. HP Scitex WB300 Supreme Inks HP Scitex WB300 Supreme HP Scitex PT10 HP Scitex PT20 C lc M lm Y K pretreatment pretreatment HP Scitex FB6700 HP Scitex FB6700 HP Scitex FB6700 HP Scitex WB300 Supreme inks are water-based, industrial inkjet inks developed for use in the HP Scitex FB6700 Printer. These inks are used on large-format media such as corrugated and compressed cardboard, polypropylene, styrene, acrylic, polycarbonate, foam board, foam PVC, and other rigid or flat substrates. Because some of these substrates may be folded or vacuum-formed when used in shortrun packaging, POP displays, and exhibition stands, HP Scitex WB300 Supreme inks produce a flexible, durable colorant layer that does not crack. The water-based formulation of HP Scitex WB300 Supreme inks facilitates an improved industrial printing environment. These inks are odorless, non-flammable, non-combustible, non-toxic, and nonreactive. They do not produce ozone emissions, no special ventilation is required to meet occupational exposure limits, and there are no requirements for air discharge permitting. HP Scitex FB6700 Printers can apply a liquid pretreatment (HP Scitex PT10 or PT20) to the substrate before imaging. This improves colorant adhesion, particularly on non-absorbent materials such as polypropylene, styrene, and others. Polymers in HP Scitex WB300 Supreme inks are cured by an in-line hot air dryer (external to the printer module) to produce prints that are UV-, water-, and abrasion-resistant according to ASTM D2565-99. These prints offer a very wide gamut with offset-like vibrancy. HP Latex Inks and HP Scitex WB300 Supreme inks both use aqueous-dispersed polymers to produce durable prints, but they are very different formulations with different chemical and physical properties. HP Latex Inks were developed for use with HP Thermal Inkjet printheads. HP Scitex WB300 Supreme inks were developed for use in Aprion® piezoelectric printheads. Compared to HP Scitex WB300 Supreme inks, HP Latex Inks do not use a pretreatment of the print medium and have a higher loading of polymers in the ink vehicle that requires curing inside the printer with a two-zone heating system. 32 Printheads scan in the Print Zone to apply ink to the print medium. The print medium is then moved (advanced) into the Curing Zone. 12