HP Scitex FB6100 Printing Technologies - Page 15

Dispersing Agent

|

View all HP Scitex FB6100 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 15 highlights

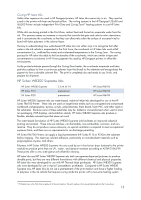

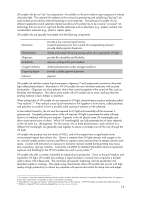

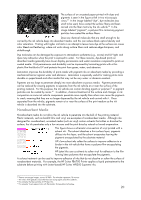

UV-curable inks do not "dry" by evaporation: inks solidify on the print medium upon exposure to intense ultraviolet light. The colorant film adheres to the surface by penetrating and solidifying ("keying") into small surface pores and by chemical bonding to some materials. Formulating UV-curable inks for different applications (and substrate chemistries) allows UV-curable inks to be a nearly "universal" ink technology that can print on rigid and flexible substrates and on absorbent (e.g., papers, textiles) and nonabsorbent materials (e.g., plastics, metals, glass). UV-curable inks are typically formulated with the following components: Monomers Photoinitiators Oligomers Surfactants Oxygen Inhibitors Dispersing Agent Colorant provide a low viscosity liquid carrier, crosslink (polymerize) to form a solid film encapsulating colorant, provide stable pigment dispersion initiate and sustain UV-curing process when ink is exposed to UV light provide film durability and flexibility improve wetting of the print medium inhibit polymerization under storage conditions provide a stable pigment dispersion pigment UV-curable ink vehicles contain liquid monomers, oligomers,38 and components sensitive to ultraviolet light called photoinitiators. Monomers in HP UV-curable inks are individual molecules with acrylate functionality. Oligomers are short polymer chains that control properties of the cured ink film, such as flexibility and elongation. This allows prints made with UV-curable inks to resist cracking when the printing material is bent, folded, or stretched. When printed dots of UV-curable ink are exposed to UV light, photoinitiators produce molecules called "free radicals".39 Free radicals cause liquid monomers to link together to form chains, called polymers, and polymers to crosslink to form a durable, solid coating of colorant on the substrate. In free radical chemistry, the ink must be exposed to UV light until essentially all the monomer is polymerized. Complete polymerization of the ink requires UV light to penetrate the entire ink layer down to its interface with the print medium. Pigments in the ink absorb some UV wavelengths and allow some transmission of others. Which UV wavelength(s) can fully penetrate the ink layer depends on the ink color (i.e., the pigment). For this reason, two or three photoinitiators, each sensitive to a different UV-wavelength, are generally used together to ensure a complete cure all the way through the ink layer. UV-curable inks produce very low levels of VOCs, and in this respect have a significantly lower environmental impact than solvent inks. Ozone is created when UV light interacts with oxygen in the air, and UV-curable printers use fans and filters to capture ozone and minimize its release into the work space. Contact with monomers or exposure to monomer aerosol created during printing may cause skin, respiratory, and eye irritation. Consult the ink MSDS for detailed information about occupational exposure and handling for the HP UV-curable inks used in your printer.40 UV-curable inks offer a number of benefits to industrial print production. Once on the print medium and exposed to UV light, UV-curable inks undergo a rapid increase in viscosity from a liquid to a durable solid in about 100 milliseconds. This minimizes dot spread, feathering, and ink penetration into absorbent media or coatings. This rapid-curing characteristic allows UV-curable inks to print with high quality at high productivity on almost any substrate with precise dot control for sharp lines and edges, 38 A "monomer" is the basic molecular element that forms a chain or matrix with other monomers in a process called polymerization. An oligomer is a short chain of monomers; a long chain or matrix of monomers is a polymer. 39 UV-curable inks may also use "cationic" chemistry for polymerization of the monomer. All HP UV-curable inks employ free radical chemistry. 40 MSDSs for Original HP inks can be downloaded from www.hp.com/go/ecodata 15