HP Scitex LX800 HP Scitex LX Printer Family - User's guide - Page 57

minutes to complete., the carriage beam into its normal position

|

View all HP Scitex LX800 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 57 highlights

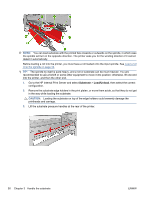

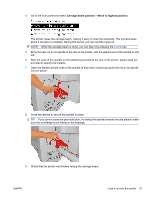

13. At the rear of the printer, measure the distance between the printer's left side plate and the left edge of the substrate. This distance should be at least 145 mm (5.7 in), otherwise the edge of the substrate may go out of the print zone and start touching the printer covers. 14. At the front of the printer, the right edge of the substrate on the tension roller should be at the same distance (A) from the right side plate as the distance measured on the input side. NOTE: There is a square indentation in the right side plate in front of the tension roller. You should measure the distance between the substrate edge and the inside of this indentation. NOTE: When loading non-elastic substrates, a difference of 2-3 mm (0.01 in) between the measurements from the rear side plate and front side plate may be acceptable without problems of skew or wrinkles. Rear Front 15. When the substrate edge is correctly positioned and the substrate is evenly tensioned, lower the tension roller lever. 16. Go to the front panel and select Carriage beam position > Move to printing (normal) to lower the carriage beam into its normal position, close to the substrate. This process takes about 2 minutes to complete. NOTE: The Move to printing (custom) position allows you to set the printhead-to-substrate distance for thick substrates or substrates that may wrinkle in the print zone, to avoid ink smearing. Be aware that raising the printhead from the substrate may give poorer print quality. WARNING! Do not insert your hands or anything else into the printer while the carriage beam is descending. ENWW Load a roll into the printer 53