Hitachi DH18DLP4 Instruction Manual - Page 18

Maintenance And Inspection

|

UPC - 717709011649

View all Hitachi DH18DLP4 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 18 highlights

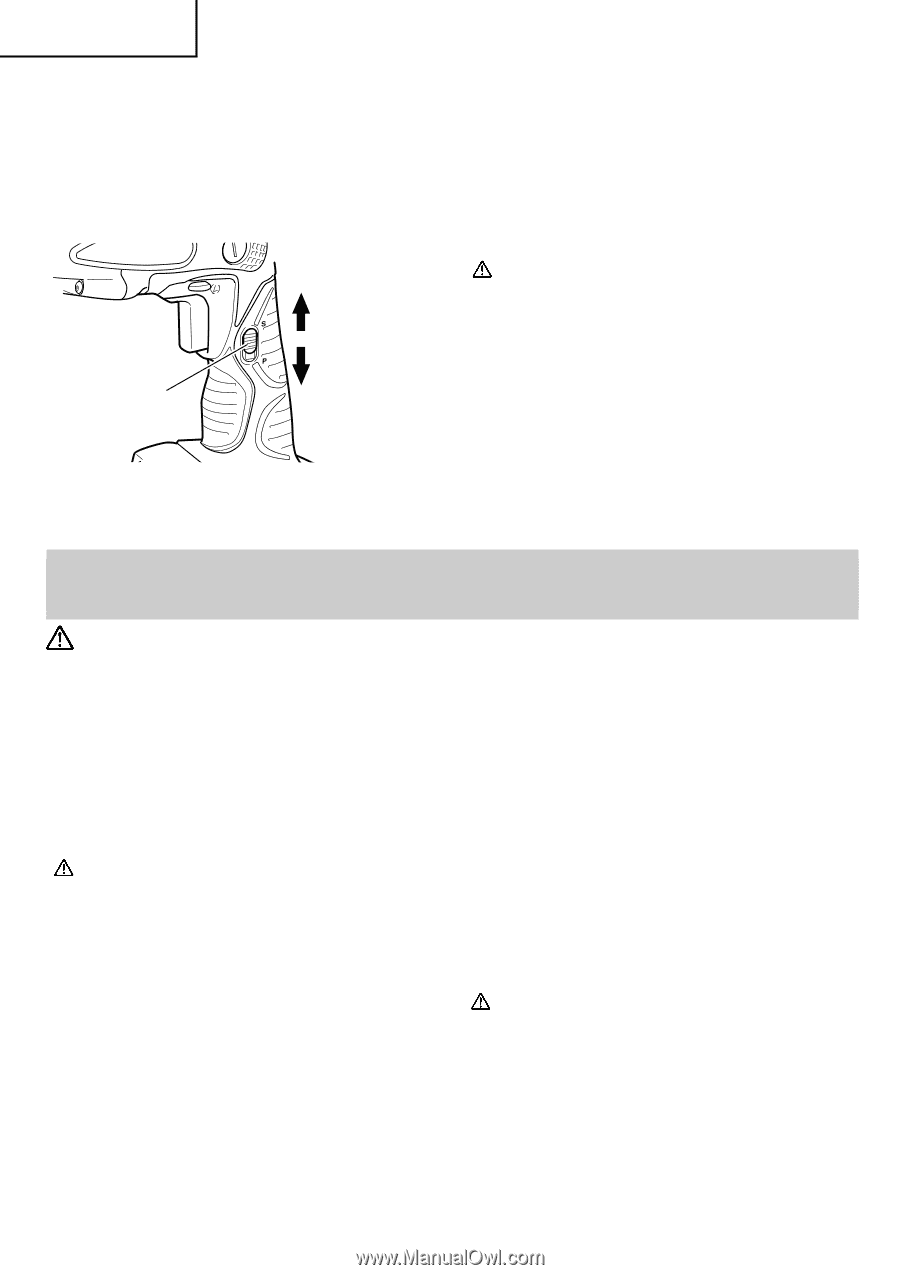

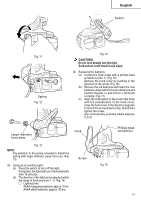

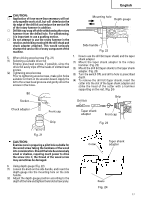

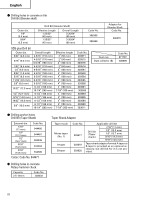

English 8. Switching between the "SAVE" and the "POWER" (1) "SAVE" mode ... decreased hammering force modes This can prevent thin drill bits which are less than The hammering force of the hammer can be 4.3 mm in diameter, from being bent or broken. increased or decreased to conform with intended (2) "POWER" mode ... increased hammering force usage, by operating the shift knob as per Fig. 25. ⅜ This can be used to speedily and efficiently drill Adjust the force to match the usage intended. holes when the drill bits which are being used are greater than 4 mm in diameter. ⅜ This can be used to drill holes into wood or metal. "SAVE" mode CAUTION: Do not drill holes in wood with the "SAVE" mode. There is a likelihood that the motor will burn out because it can easily lock up due to the low power. Shift knob "POWER" mode Fig. 25 MAINTENANCE AND INSPECTION CAUTION: Pull out battery before doing any inspection or maintenance. 1. Inspecting the drill bits NOTE: Since use of a dull tool will cause motor When replacing the carbon brush with a new one, malfunctioning and degraded efficiency, replace be sure to use the Hitachi Carbon Brush Code No. the drill bit with a new one or resharpening without 328481. delay when abrasion is noted. 2. Check the Screws 5. Replacing carbon brushes Loose screws are dangerous. Regularly inspect Take out the carbon brush by first removing the them and make sure they are tight. brush cap and then hooking the protrusion of the carbon brush with a flat head screw driver, etc., as CAUTION: shown in Fig. 18. Using this power tool with loosened, screws is When installing the carbon brush, choose the extremely dangerous. direction so that the nail of the carbon brush agrees with the contact portion outside the brush tube. 3. Maintenance of the motor Then push it in with a finger as illustrated in Fig. The motor unit winding is the very "heart" of the 19. Lastly, install the brush cap. power tool. Exercise due care to ensure the winding does not CAUTION: become damaged and/or wet with oil or water. ● Be absolutely sure to insert the nail of the carbon 4. Inspecting the carbon brushes (Fig. 17) brush into the contact portion outside the brush The motor employs carbon brushes which are tube. (You can insert whichever one of the two consumable parts. Since and excessively worn nails provided.) carbon brush can result in motor trouble, replace ● Caution must be exercised since any error in this the carbon brush with new ones when it becomes operation can result in the deformed nail of the worn to or near the "wear limit". In addition, carbon brush and may cause motor trouble at an always keep carbon brushes clean and ensure that early stage. they slide freely within the brush holders. 18