Husqvarna 226HD75S Owners Manual - Page 14

Maintenance

|

View all Husqvarna 226HD75S manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 14 highlights

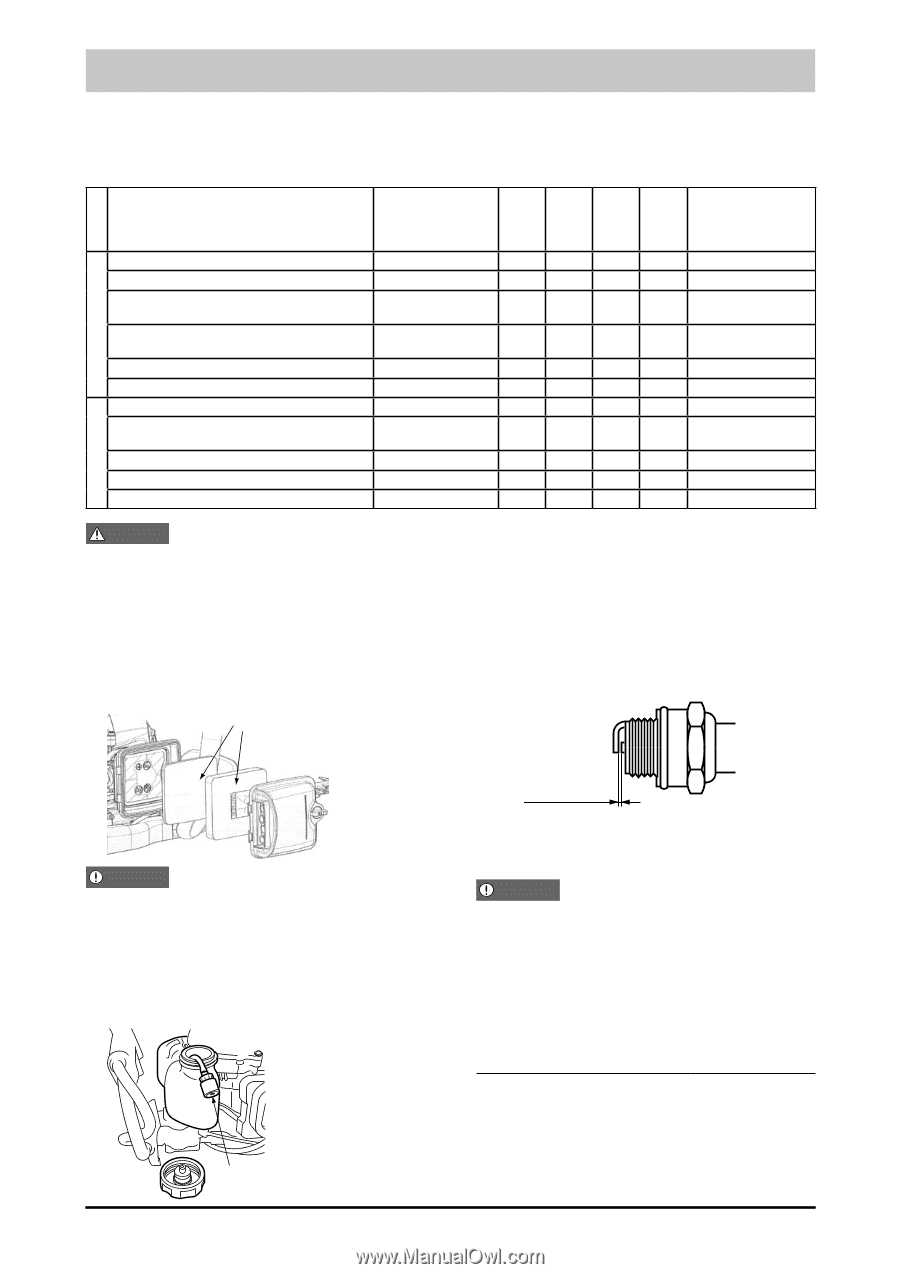

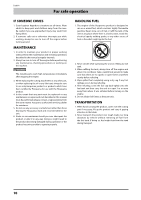

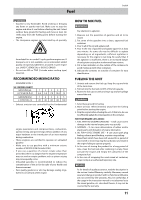

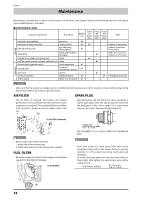

English Maintenance Maintenance, replacement, or repair of the emission control device and systems may be performed by any non-road engine repair establishment or individual. ■ MAINTENANCE CHART System/components Procedure Every Every Every Before 25 50 100 use hours hours hours after after after Note ENGINE fuel leaks, fuel spillage fuel tank, air filter, fuel filter idle adjusting screw spark plug wipe out ✔ inspect/clean ✔✔ see adjusting idling speed ✔ clean and readjust plug gap ✔ replace, if necessary replace carburetor if necessary GAP : 0.6 ~ 0.7 mm replace, if necessary TRIMMER cylinder fins, intake air cooling vent clean ✔ muffler, spark arrester, cylinder exhaust port clean ✔ throttle lever, ignition switch check operation ✔ cutting parts replace if something's wrong ✔ gear case grease ✔ screws/nuts/bolts tighten/replace ✔ ✔ not adjusting screws debris guard make sure to attach ✔ WARNING Make sure that the engine has stopped and is cool before performing any service to the machine. Contact with moving cutting head or hot muffler may result in a personal injury. AIR FILTER SPARK PLUG • The air filter, if clogged, will reduce the engine performance. Check and clean the filter element in warm, soapy water as required. Dry completely before installing. If the element is broken or shrunk, replace with a new one. (1) • Starting failure and mis-firing are often caused by a fouled spark plug. Clean the spark plug and check that the plug gap is in the correct range. For a replacement plug, use the correct type specified by Husqvarna. (1) Air filter element IMPORTANT • How to attach two air filter elements 1. Attach thin element previously 2. Attach thick element so that stamp side is outside FUEL FILTER • When the engine runs short of fuel supply, check the fuel cap and the fuel filter for blockage. (1) Fuel filter 0.025 inch 0.6 ~ 0.7 mm • REPLACEMENT PLUG IS NGK CMR7H OR CHAMPION RZ7C. IMPORTANT • Note that using any spark plug other than those designated may result in the engine failing to operate properly or in the engine becoming overheated and damaged. • To install the spark plug, first turn the plug until it is finger tight, then tighten it a quarter turn more with a socket wrench. TIGHTENING TORQUE: 87~121 in-lbs (9.8~13.7 N.m) (1) 14