Husqvarna MZ 5225 Owners Manual - Page 54

Hydraulic Pump, Fluid Change, Purging Procedures, hours - change hydraulic fluid

|

View all Husqvarna MZ 5225 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 54 highlights

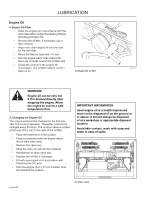

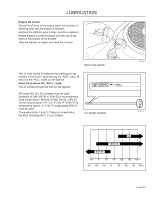

LUBRICATION Hydraulic Pump Fluid Change This transaxle is designed with an external filter for ease of maintenance. To ensure constant fluid quality levels and longer life an oil filter change interval of every 200 hours is recommended. The following procedure can be performed with the pump installed in the vehicle, and the vehicle on level ground. Apply the bypass valve and lock the vehicle parking brake. 1. Place an oil drain pan with a two gallon capacity beneath the oil filter. Remove the oil filter from the pump. 2. After the oil has drained, wipe the filter base surface off and apply a film of new oil to the gasket of the new replacement filter. 3. Prefill the oil filter with new oil and install the new filter by hand. Turn ¾ to one full turn after the filter gasket contacts the filter base surface. 4. Drain old oil filters of all free-flowing oil prior to disposal. Place used oil in appropriate containers and dispose of it in accordance with laws in your area. 5. Remove the cap from the pump's tank located on the vehicle frame. 6. Fill reservoir with SAE 10W30 oil to just above the MIN-ADD line on the reservoir. After purging, check levels and add oil if necessary. 7. Reinstall the tank cap by hand. Do not overtighten. 8. Proceed to the purge procedure. Purging Procedures Due to the effects air has on efficiency in hydrostatic drive applications, it is critical to purge the system. These purge procedures should be implemented any time a hydrostatic system has been opened to facilitate maintenance or any additional oil has been added to the system. Resulting symptoms in hydrostatic systems may be: 1. Noisy operation. 2. Lack of power or drive after short term operation. 3. High operation temperature and excessive expansion of oil. 4. Shortened component life. English-54 2 3 1 1. Pump filter 2. Pump reservoir 3. Fluid fill lines Changing the hydraulic pump oil filter 8061-016 Before starting, make sure the pump is at the proper oil level. If not, fill to the specifications outlined prior. The following procedures are best performed with the vehicle drive wheels off the ground, then repeated under normal operating conditions. 1. Disengage the brake if activated. 2. With the bypass valve open and the engine running at fast idle, slowly move the directional control in both forward and reverse directions (5 or 6 times). As air is purged from the unit, the oil level will drop. 3. With the bypass valve closed and the engine running, slowly move the directional control in both forward and reverse directions (5 to 6 times). Check the oil level and add oil as required after stopping the engine. 4. It may be necessary to repeat Steps 2 and 3 until all the air is completely purged from the system. When the transaxle operates at normal noise levels and moves smoothly forward and reverse at normal speeds, the transaxle is considered purged. 5. After the vehicle has been used two times, the oil level should be checked while the oil is cold and adjusted accordingly.