Intel Q9400S Design Guidelines - Page 51

Material and Recycling Requirements

|

UPC - 735858207973

View all Intel Q9400S manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 51 highlights

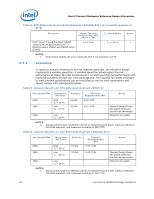

Intel® Thermal/Mechanical Reference Design Information 5.3.2 5.3.3 5.4 Power Cycling Thermal performance degradation due to TIM degradation is evaluated using power cycling testing. The test is defined by 7500 cycles for the case temperature from room temperature (~23 ºC) to the maximum case temperature defined by the thermal profile at TDP. Thermal Test Vehicle is used for this test. Recommended BIOS/Processor/Memory Test Procedures This test is to ensure proper operation of the product before and after environmental stresses, with the thermal mechanical enabling components assembled. The test shall be conducted on a fully operational motherboard that has not been exposed to any battery of tests prior to the test being considered. Testing setup should include the following components, properly assembled and/or connected: Appropriate system motherboard Processor All enabling components, including socket and thermal solution parts Power supply Disk drive Video card DIMM Keyboard Monitor The pass criterion is that the system under test shall successfully complete the checking of BIOS, basic processor functions and memory, without any errors. Material and Recycling Requirements Material shall be resistant to fungal growth. Examples of non-resistant materials include cellulose materials, animal and vegetable based adhesives, grease, oils, and many hydrocarbons. Synthetic materials such as PVC formulations, certain polyurethane compositions (e.g., polyester and some polyethers), plastics which contain organic fillers of laminating materials, paints, and varnishes also are susceptible to fungal growth. If materials are not fungal growth resistant, then MILSTD-810E, Method 508.4 must be performed to determine material performance. Material used shall not have deformation or degradation in a temperature life test. Any plastic component exceeding 25 grams must be recyclable per the European Blue Angel recycling standards. Thermal and Mechanical Design Guidelines 51