JET Tools JWBS-18-3 User Manual - Page 29

Mechanical and electrical problems

|

View all JET Tools JWBS-18-3 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 29 highlights

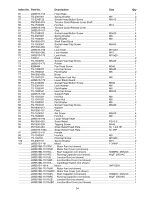

12.2 Mechanical and electrical problems Table 5 Symptom Machine will not start/restart or repeatedly trips circuit breaker or blows fuses. Probable Cause No incoming power. Cord damaged. Band Saw frequently trips. Building circuit breaker trips or fuse blows. Overload automatic reset has not reset. Switch or motor failure (how to distinguish). Motor overheated. Motor failure. Miswiring of unit. Switch failure. Band Saw does not attain full speed. Extension cord too light or too long. Low current. * WARNING: Some corrections may require a qualified electrician. Correction * Verify machine connections. Replace cord. One cause of overloading trips which are not electrical in nature is too heavy a cut. The solution is to reduce feed pressure into the blade. If this does not resolve the issue, check for loose electrical lead. Verify that band saw is on a circuit of correct size. If circuit size is correct, there is probably a loose electrical lead. Check amp setting on motor starter. When the 3HP and 5HP Band Saw overloads on the circuit break built into the motor starter, it takes time for the machine to cool down before restart. Allow machine to adequately cool before attempting restart. If problem persists, check amp setting on the motor starter inside the electrical box. If you have access to a voltmeter, you can separate a starter failure from a motor failure by first, verifying incoming voltage at 115 +/-10% (or 230+/-10%) and second, checking the voltage between starter and motor at 115 +/-10% (or 230+/-10%). If incoming voltage is incorrect, you have a power supply problem. If voltage between starter and motor is incorrect, you have a starter problem. If voltage between starter and motor is correct, you have a motor problem. Clean motor of dust or debris to allow proper air circulation. Allow motor to cool down before restarting. If electric motor is suspect, you have two options: Have a qualified electrician test the motor for function or remove the motor and take it to a qualified electric motor repair shop for testing. Double check to confirm all electrical connections are correct. Refer to wiring diagram to make needed corrections. If the start/stop switch is suspect, you have two options: Have a qualified electrician test the switch for function, or purchase a new start/stop switch and establish if that was the problem on change-out. Replace with adequate size and length cord. Contact a qualified electrician. 29