Jenn-Air JDRP536HM Installation Instructions - Page 17

To Convert Gas Pressure Regulator from Natural, Gas to Propane

|

View all Jenn-Air JDRP536HM manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 17 highlights

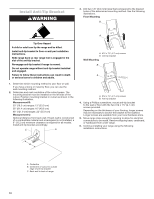

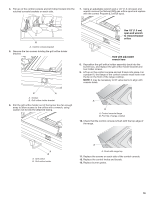

To Convert Gas Pressure Regulator from Natural Gas to Propane NOTE: Door must be removed in order to remove or replace kick plate. Refer to the "Remove Door" section. 1. Lift the kick plate up and off of the kick plate tab. 5. Remove spring retainer from the cap by turning the spring retainer counterclockwise. Locate the "LP" and "NAT" position on the spring retainer. Turn over the spring retainer so the "LP" arrow is pointing toward the cap. A NAT LP B NAT LP D E NAT LP A B C A. Kick plate B. Kick plate tab C. Kick plate slot 2. Gently lay kick plate aside to avoid scratching. 3. Locate the gas pressure regulator at the left rear of the range. A A. Gas pressure regulator 4. Remove the gas pressure regulator cap by using a large flat-blade screwdriver, turning the regulator cap counterclockwise. When the cap is removed, do not lose the metal seal. NOTE: Do not remove the spring beneath the cap. NAT LP C A. Access cap B. Metal seal C. Gas pressure regulator D. Spring retainer in NAT position E. Spring retainer in LP position 6. Tighten the gas pressure regulator cap by using a large flatblade screwdriver, turning the regulator cap clockwise. 7. Test the gas pressure regulator and gas supply line. The regulator must be checked at a minimum 1" (2.5 cm) water column above the set pressure. The inlet pressure to the regulator should be as follows for operation and checking the regulator setting: Propane Gas: Minimum pressure: 10" (25.4 cm) WCP Maximum pressure: 14" (35.6 cm) WCP Gas Supply Pressure Testing Gas supply pressure for testing regulator must be at least 1" (2.5 cm) water column pressure above the manifold pressure shown on the model/serial/rating plate. Line pressure testing above 1/2 psi (3.5 kPa) gauge (14" [35.6 cm] WCP) The range and its individual shut-off valve must be disconnected from the gas supply piping system during any pressure testing of that system at test pressures in excess of 1/2 psi (3.5 kPa). Line pressure testing at 1/2 psi (3.5 kPa) gauge (14" [35.6 cm] WCP) or lower The range must be isolated from the gas supply piping system by closing its individual manual shut-off valve during any pressure testing of the gas supply piping system at test pressures equal to or less than 1/2 psi (3.5 kPa). 17