Lexmark MX810 Card Stock & Label Guide - Page 23

Label components, Liners

|

View all Lexmark MX810 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 23 highlights

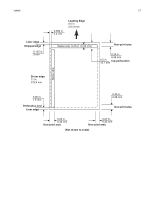

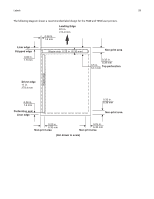

Labels 23 The following are the rib locations for the Lexmark MS710, MS711, MS810, MS811, MS812, MX710, MX711, MX810, MX811, and MX812 printer models. 221.6 0.6 204.0 0.6 189.6 0.4 170.5 0.4 153.0 0.4 134.0 0.4 115.6 0.4 94.4 0.2 83.5 0.2 68.5 0.2 52.5 0.2 36.5 0.2 20.5 0.1 5.6 0.1 Reference Edge Label components Labels are composed of three basic parts: the liner, the adhesive, and the face sheet. Labels may also have topcoats that affect printing. Choosing appropriate materials for each of these label components will help ensure reliable printing. Liners The liner, also known as the carrier or backing, is the material onto which the label is attached. The liner carries the label through the printer and directly affects feed reliability. Liner weights and construction vary based on the printable face stock used. For more information, see "Face sheet (printable stock)" on page 25. Tissue‑backed, plain bond, or bond‑like, porous, lay‑flat liners are preferred. Liners constructed for use with high‑speed laser printers (50 or more pages per minute) may not produce acceptable results. A liner should bend easily and go back to its original flat state when released. If the form remains bent, then it may cause paper jams or damage to the edge of the sheet, particularly in earlier printer models using a corner buckler rather than an auto compensator to separate the sheets. The following table shows which printers use a corner buckler and which use an auto compensator. Note: If your printer is not listed here, then contact your Lexmark representative to verify which method your printer uses to separate sheets of labels.