Lexmark MX826 Paper and Specialty Media Guide PDF - Page 11

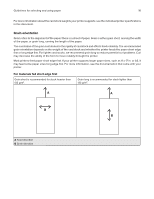

Debossing and embossing, Metallics, Basic form design, 35 mm 0.25 in. on both sides of the form.

|

View all Lexmark MX826 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 11 highlights

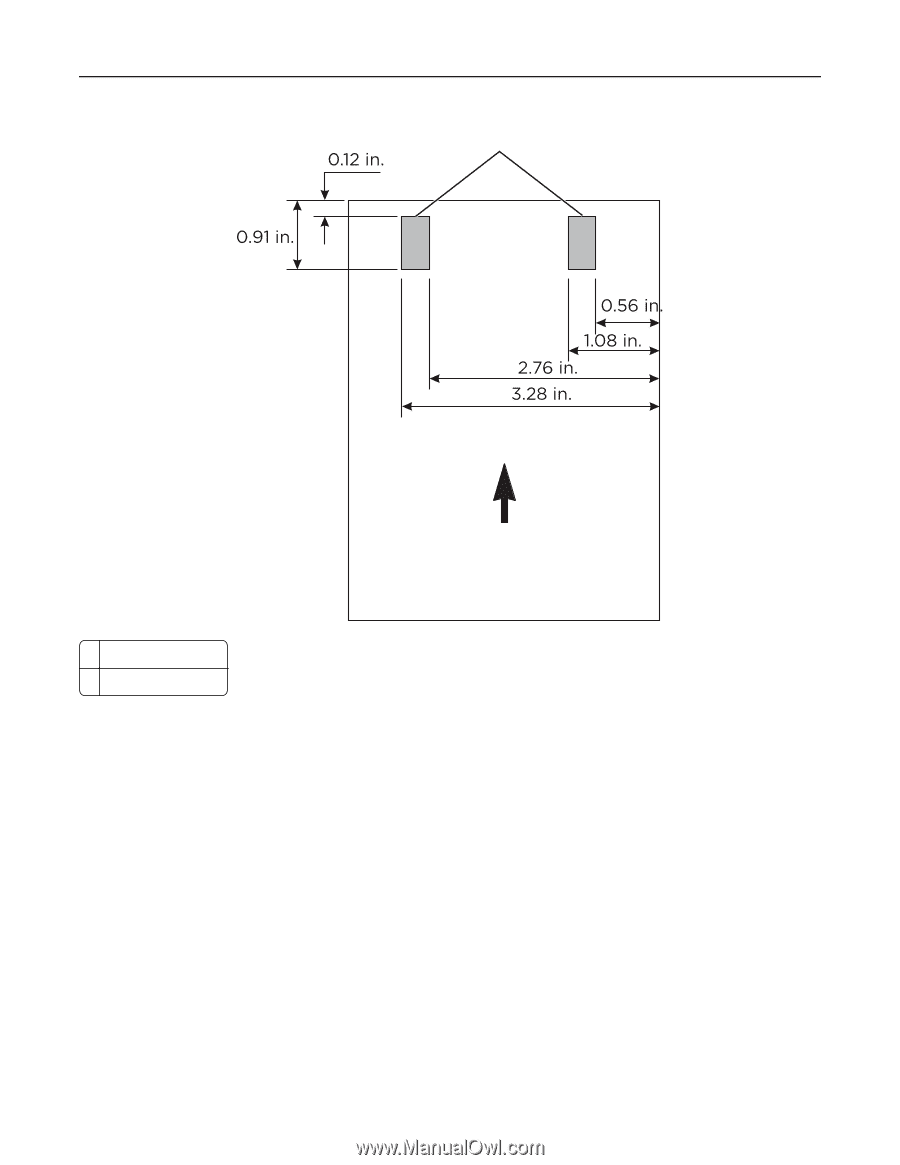

Design considerations for purchasing paper 11 A B A Pick roller location B Feed direction Debossing and embossing Avoid debossing and embossing materials. The use of these materials may lead to nesting and double‑sheet feeds, and the fusing process significantly reduces the height of the raised image. Printing too close to embossments results in poor print quality and poor fuse grade. Metallics We do not recommend using metallics in forms, whether in inks or other materials, due to their conductivity and their ability to bleed charge. This property can interfere with toner transfer and cause poor print quality. Basic form design When designing forms, include a non‑print area of 8.38 mm (0.33 in.) at the top and bottom of the form and 6.35 mm (0.25 in.) on both sides of the form. In general, portrait orientation is the preferred layout, especially if you are printing bar codes. Choosing landscape orientation may cause the variations in paper path speed to produce spacing variations when printing bar codes.