LiftMaster MGJ Installation Manual - Page 25

Troubleshooting, Remote Cannot

|

View all LiftMaster MGJ manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 25 highlights

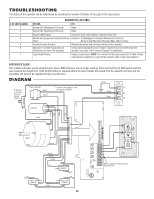

TROUBLESHOOTING Technical Support 1-800-528-2806 CONDITION POSSIBLE CAUSE FIX OPERATOR WILL NOT RESPOND TO ANY A) No power COMMANDS B) Stop circuit not complete ➤ Verify primary line voltage (120 Vac, 60 Hz) is present at terminals L1 & L2. The LED will flash when power is present. ➤ Verify Stop Button input (terminals 3 & 5) is properly wired and stop button is not stuck. C) Stuck button on 3-button control station D) Interlock input activated E) Motor overload tripped F) Accessory failure ➤ Verify that all buttons are actuating freely and releasing properly. ➤ Verify jumper is located at terminals 3 & 4 if interlock is not present. ➤ Verify interlock is properly wired and not activated. ➤ Overload is internal within motor. Allow to cool and retry. ➤ Attempt to close by holding the CLOSE button for more than 5 seconds. If door closes, check accessory for proper wiring, polarity, connections or damage. OPERATOR MAKES NOISE BUT DOOR DOES NOT MOVE ➤ Verify photoelectric sensors are aligned or sensing edge is not activated. G) Possible component failure ➤ Call Technical Support for assistance. A) Clutch slipping ➤ Adjust clutch, see ADJUSTMENT section. B) Brake not releasing (if present) ➤ Verify brake assembly operation and wiring. OPERATOR MOVES IN THE WRONG DIRECTION DOOR DRIFTS AFTER OPERATOR STOPS C) Door operation problem OPEN and CLOSE button wiring connection reversed A) Door not balanced properly ➤ Disconnect trolley and check door for proper operation. ➤ Check 3-button control wiring. ➤ Disconnect trolley assembly and check door for proper operation. DOOR OPENS/ CLOSES TOO FAR DOOR REVERSES UNEXPECTEDLY TTC NOT FUNCTIONING B) Clutch slipping C) Brake not functioning properly Limits not adjusted properly Intermittent Entrapment Protection Device activation A) Monitored Entrapment Protection Devices ➤ Adjust clutch, see ADJUSTMENT section. ➤ Check brake mechanism to ensure brake lever is free and brake pads are engaging the brake disc. ➤ Adjust limits. See ADJUSTMENT section. ➤ Check all connections. ➤ Check all connections. Verify photoelectric sensors are not blocked and the sensing edge is not activated. B) TTC temporarily disabled ➤ Close and Open the door. TTC will be re-enabled. C) TTC not programmed properly ➤ Reprogram TTC. See PROGRAMMING TTC section. RADIO FUNCTIONALITY NOTE: Built in radio receiver compatible with all LiftMaster 315 MHz remote control devices. NO RESPONSE A) Remote control is not programmed ➤ See PROGRAMMING REMOTE CONTROLS section. REMOTE CANNOT BE LEARNED B) Remote control not compatible C) Low battery A) Low battery B) Remote control not compatible ➤ Obtain qualified LiftMaster remote control device. ➤ Replace battery. ➤ Replace battery. ➤ Obtain qualified LiftMaster remote control device. POOR RADIO RANGE A) Low battery in remote ➤ Replace battery. B) Antenna not configured ➤ See SETUP RADIO ANTENNA. C) Ambient radio interference or building structural issue ➤ Use EXTERNAL ANTENNA kit (see ACCESSORIES page). 25