LiftMaster SL585UL SL585UL SL595UL Single Phase Wiring Diagram - Page 1

LiftMaster SL585UL Manual

|

View all LiftMaster SL585UL manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 1 highlights

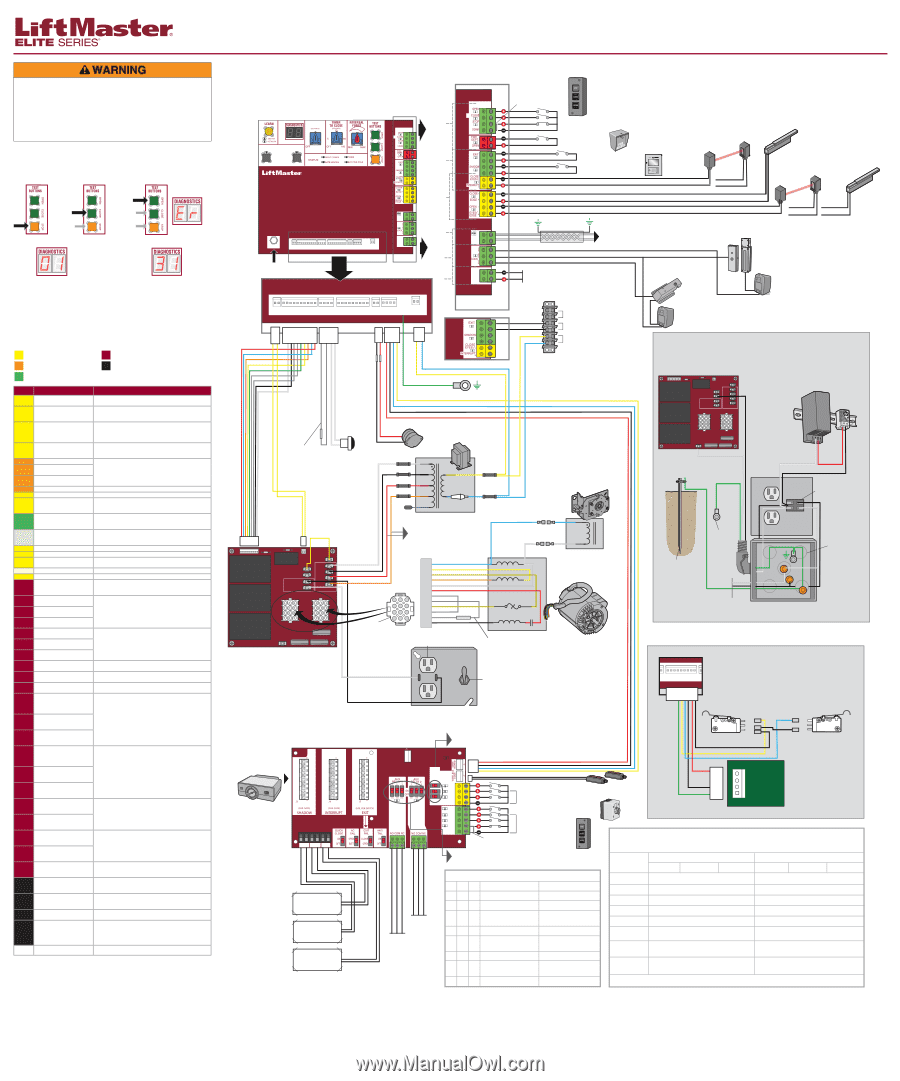

SINGLE PHASE WIRING DIAGRAM Models SL585UL and SL595UL To reduce the risk of INJURY or DEATH: • DISCONNECT power BEFORE installing or servicing operator. • Replace ONLY with fuse of same type and rating. • To be compliant with UL325 and industry safety guidelines, qualified monitored external entrapment protection devices such as photoelectric sensors or edge sensors are required to be installed with this operator at each entrapment zone. Use ONLY LiftMaster approved entrapment protection devices (refer to the accessory page of manual). • See manual prior to servicing regarding maintenance and required safety testing. Diagnostic Codes TO VIEW THE CODES: Press and hold STOP... ...then press and hold CLOSE... ...then press and hold OPEN until "Er" shows. CONTROL BOARD BIPART DELAY 4 2 6 OPEN LEFT OPEN 8 RIGHT HANDING LOOPS CONTROLS 3-BUTTON CONTROL STATION Jumper N.C. FIRE DEPARTMENT OR EXIT LOOP SHADOW LOOP ACCESS CONTROL DEVICE INTERRUPT LOOP or PHOTOELECTRIC SENSORS for CLOSE cycle EDGE SENSOR for CLOSE cycle PHOTOELECTRIC SENSORS for OPEN cycle EDGE SENSOR OR POWER LOCKS GATES PROTECTION DUAL ENTRAPMENT COMM LINK BA The operator will show the code sequence number followed by the code number: A SECOND LATER.... CODE SEQUENCE NUMBER The first number shown is the most recent code (example: "01"). The display will show the sequence of codes that occurred starting with "01" and going up to code "20". CODE NUMBER The second number shown after the code sequence number is the code itself (31-99, example" "31"). TO SCROLL THROUGH THE SAVED CODES: Press the OPEN button to cycle to the most recent code ("01"). Press the CLOSE button to cycle to the oldest code (up to "20"). CODE COLOR KEY: LiftMaster System External Entrapment Protection Installed System Inherent Entrapment Protection Informational MEANING SOLUTION 31 Main control board has Disconnect all power, wait 15 seconds, then reconnect power experienced an internal failure. (reboot). If issue continues, replace main control board. Max-Run-Time Exceeded Error Attempt to run and review for duration and obstructions. Max- 35 Run-Time can be re-measured by saving one or both of the limits again. Product ID Error Was the control board just replaced? If so, erase limits, enter limit 36 setup mode and set limits. If not, disconnect all power, wait 15 seconds, then reconnect power before changing product ID harness. Product ID Failure 37 Unplug product ID harness then plug back in. Disconnect all power, wait 15 seconds, then reconnect power before replacing product ID harness. 43 Failure or missing EXIT loop Check loop wiring throughout connection. May be a short in the 44 Failure or missing SHADOW loop loop, or an open connection in the loop (LiftMaster Plug-in Loop Detector only). 45 Failure or missing INTERRUPT loop 46 Wireless edge battery low Replace batteries in wireless edge. 47 Power board fault Relay fault detected in the power board. Replace the power board. Run-Distance Error Limits are less than 4 feet apart or longer than what was learned. 50 Check limit positions and proper switch function. Run-distance can be re-learned by setting the handing again. Brownout occurred 53 AC/DC board supply dipped below allowable level. Review power supply and wiring. If rebooting, ensure enough time for discharge of power to force a fresh boot. Wireless Second Operator Check the second operator for power. If OFF, restore power and 54 Communication Error try to run the system. If powered, deactivate the wireless feature and then re-learn the second operator. 55 System AC Overvoltage Call utility. 56 System AC Undervoltage Check wiring and wire gauge to operator. 57 Limit Error - Stuck Switch Check switch for proper operation. Check harness for shorts. Replace if defective. 58 Limit Error - Wrong Switch Check motor wiring. 59 Missing Power Board Check harness for shorts. Check for presence of power board. Minimum number of monitored Review monitored entrapment protection device connections. 60 entrapment protection devices Slide gate operators require a minimum of two external safety not installed. devices; one in the close and one in the open direction 61 CLOSE EYE/INTERRUPT held more than 3 minutes Check wired input on main board; check for alignment or obstruction. 62 CLOSE EDGE held more than 3 minutes 63 OPEN EYE/EDGE held more than 3 minutes 64 CLOSE EYE/INTERRUPT held more than 3 minutes Check wired input on expansion board; check for alignment or obstruction. 65 CLOSE EYE/EDGE held more than 3 minutes 66 OPEN EYE/EDGE held more than 3 minutes 67 Wireless edge triggered more Check wired input for wiring issue or obstruction. than 3 minutes 68 Wireless edge loss of monitoring Check wireless edge inputs. 69 Wireless edge triggered IF an obstruction occurred, no action required. If an obstruction did NOT occur, check inputs and wiring. CLOSE EYE/INTERRUPT IF an obstruction occurred, no action required. If an obstruction 70 triggered, causing reversal, preventing close, or resetting did NOT occur, check alignment, inputs, and wiring on main board. TTC CLOSE EDGE triggered, causing 71 reversal, preventing close, or canceling TTC OPEN EYE/EDGE triggered, 72 causing reversal or preventing opening CLOSE EYE/INTERRUPT IF an obstruction occurred, no action required. If an obstruction 73 triggered, causing reversal, preventing close, or resetting did NOT occur, check alignment, inputs, and wiring on expansion board. TTC CLOSE EYE/EDGE triggered, 74 causing reversal and preventing close or canceling TTC OPEN EYE/EDGE triggered, 75 causing reversal or preventing opening Close input (EYE/EDGE) Check inputs and communication method between operators, 80 communication fault from other either wired bus or radio. Ensure operator is powered. May have operator to erase the wireless communication and reprogram the two Open input (EYE/EDGE) operators. 81 communication fault from other operator Close input (EYE/EDGE) Check the connections between the main board and the expansion 82 communication fault (expansion board. board) Open input (EYE/EDGE) 83 communication fault (expansion board) Non-monitored device detected Non-monitored contact closure devices are not supported. Make 84 on the wireless safety system sure connected devices are monitored. Check edges for proper orientation and resistive end cap connection. Force Reversal 91 Look for obstruction, if no obstruction, check that the mechanical assembly is engaged and free to move. Refer to manual for Limit and Force Adjustment, and Obstruction Test. RPM / STALL Reversal Check for obstruction. If no obstruction, check the operator cable 93 wiring and that the operator arm is engaged and free to move. Replace RPM assembly. 95 AC motor no start condition Motor failed to start. Check for an obstructed gate or binding mechanism. Check start capacitor connections and condition. Current Sensor Fault 96 A fault was detected on the current sensor. Make sure the current sensor is connected to the main control board. Check the current sensor harness for an open or short. The operator will need a power cycle to resume operation after correcting the fault. If the fault continues, replace the power board. 99 Normal Operation No action required ANTENNA CURRENT MOTOR DRIVE SENSOR ID RESET RPM & LIMITS ALARM EXP. BOARD 24 VAC IN ANTENNA GND CLASS 2 SUPPLY 24 VAC 500 mA MAX CLASS 2 SUPPLY 24 VAC 500 mA MAX COMM LINK BA N.F. COM N.O. ACCESSORY POWER 24VOC 0.5A Maximum Shielded Twisted Pair Cable (Primary/Secondary link to other gate operator) Ground the shield of the cable to the chassis ground of each operator. SOLENOID LOCK (Optional) OR MAGLOCK (Optional) ACCESSORY CURRENT MOTOR DRIVE RPM & LIMITS ALARM EXP. 24 VAC IN SENSOR ID RESET BOARD GND 21 Red Blue Orange Yellow Green Gray Purple Black White 10 9 8 7 6 5 4 3 2 1 4 3 2 1 21 4321 White PRODUCT ID SL585UL - Blue SL595UL - Black RESET BUTTON ALARM Red Black COM Blue Yellow Yellow Blue OPTIONAL ACCESSORY WIRING EXIT ACCESSORY POWER 24VAC 2.2 AMPS MAX Connect external radios to DC control board accessory power only. Yellow Blue Black Red 120 Yellow Yellow 208 24 VAC 240 480 3.15A FUSE SOLENOID BRAKE 1 2 3 4 5 6 789 J10 J15 J14 J13 Yellow 12 J8 CURRENT SENSOR SWITCH (YELLOW) PWR IN HOT (BLACK) 120V (BLACK) OUTLET (WHITE) 120V J11 J12 J2 J4 J6 J16 SWITCH (ORANGE) COMM (WHITE) 120V (BLACK) 208V (RED) 240V (ORANGE) TRANSFORMER 240V J9 J17 J5 J3 J7 120V 240V PWR IN NEUTRAL (WHITE) J1 POWER BOARD SINGLE PHASE TRANSFORMER To configure the motor for 208V, swap the orange and red wires and plug motor into the 240V position. Blue White White Black Red Orange MOTOR HARNESS 3 1 12 10 12 Blue 11 Yellow 10 Yellow/Black 9 Orange 8 White 7 6 Red Purple 5 4 Yellow/Black Purple 3 2 Black 1 ACCESSORY POWER OUTLET Attach to metal chassis RUN 1 RUN 2 THERMAL SWITCH START HORSE POWER ID 1/2 HP - Yellow 1 HP - Purple 1 1/2 HP - Blue White AC POWER SWITCH MOTOR (Not Provided) (Not Provided) Power Wiring POWER BOARD Single Phase J10 J8 J15 J14 J13 J2 J4 J6 J16 J9 J17 J5 J3 J7 CURRENT SENSOR SWITCH (YELLOW) PWR IN HOT (BLACK) 120V (BLACK) OUTLET (WHITE) 120V SWITCH (ORANGE) COMM (WHITE) 120V (BLACK) 208V (RED) 240V (ORANGE) TRANSFORMER 240V J11 J12 HEATER (Optional Accessory) 120V PWR IN NEUTRAL (WHITE) J1 240V White Black White Red Black AC POWER SWITCH Attach to metal chassis Earth Ground Rod NEUTRAL HOT GROUND INCOMING POWER White Black Green JUNCTION BOX Attach to metal chassis CONTROL BOARD RPM & LIMITS ALA SET Limit Switch Wiring Black EXPANSION BOARD PLUG-IN LOOP DETECTOR Model LOOPDETLM SHADOW INTERUPT EXIT TO MAIN BOARD OPEN CLOSE These switches determine if the corresponding photoelectric sensor or edge sensor will function for the OPEN or CLOSE cycle. POWER 4 321 E1YE ONLY EYE/EDGE 2 EYE/EDGE 3 COM SBC OPN CLS STP COM WIRELESS EDGE KIT Model LMWEKITU PHOTOELECTRIC SENSORS PHOTOELECTRIC SENSORS or EDGE SENSORS SINGLE BUTTON CONTROL STATION N.C. Jumper 3-BUTTON CONTROL STATION These switches control how the Auxiliary Relays will function. Normally Closed Common Normally Open Normally Closed Common Normally Open INTERRUPT LOOP SHADOW LOOP EXIT LOOP AUXILIARY RELAY 2 AUXILIARY RELAY 1 SWITCH SETTINGS 1 23 RELAY 1 OFF OFF OFF Relay always off RELAY 2 Relay always off OFF OFF ON Energizes at open limit Energizes at open limit OFF ON OFF Energizes when not at close limit Energizes when not at close limit OFF ON ON Energizes when motor is on Energizes when motor is on ON OFF OFF Energizes 3 seconds prior and during gate motion Energizes 3 seconds prior and during gate motion ON ON OFF Not used ON OFF ON Energizes when gate is tampered with Not used Energizes when gate is tampered with ON ON ON LEDs will blink cycle count Not used 987654321 CLOSE Limit Switch NF NO C Black Yellow Red 4 4 3 3 Black 2 2 Green 1 1 Blue Black OPEN Limit Switch NF NO C RPM BOARD RED/GREEN LIGHT FUNCTIONALITY Red light wired to AUX RELAY 1. Green light wired to AUX RELAY 2. GATE STATE CLOSED AUX RELAY 1 SWITCHES 1 OFF 2 OFF 3 OFF Red light OFF* AUX RELAY 2 SWITCHES 1 ON 2 ON 3 ON Green light OFF OPENING OPEN CLOSING Defined Mid Stop Undefined Mid Stop Timer more than 5 seconds Red light ON/FLASH Red light OFF Red light ON/FLASH n/a Red light ON Red light OFF Green light OFF Green light ON Green light OFF n/a Green light OFF Green light ON Timer less than 5 seconds Red light ON/FLASH Green light OFF * For red light ON when gate is closed, set switch 1 on AUX RELAY 1 to ON LiftMaster.com © 2018, LiftMaster All Rights Reserved 01-39240-6