LiftMaster T T-LOGIC 3 Manual - Page 13

Control Station Wiring And Installation, Control Wiring Connections, External Radio Wiring - two button remote

|

View all LiftMaster T manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 13 highlights

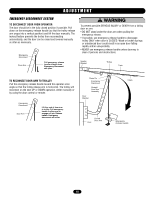

CONTROL STATION WIRING AND INSTALLATION CONTROL WIRING CONNECTIONS 1. Connect control wires to the P1 terminal block located on the logic board as shown. 2. Connect conduit with all control wires through the conduit hole in the electrical box enclosure marked with the label shown below. CONTROL WIRING USE COPPER WIRE ONLY 40-10032B 3. Apply power to the operator. Press OPEN push button and observe direction of door travel and then Press the STOP button. If door did not move in the correct direction, check for improper wiring at the control station or between operator and control station. NOTE: In "Diag" mode the 3-button control station can be tested to verify correct wiring of Open, Close and Stop buttons without moving the door. If the door moves in the wrong direction and or the limits move in the wrong direction, simply move the motor direction jumper located on the logic board from the factory default setting (STD) to the (REV) pins. This will change the motor rotation as well as the functional position of the OPEN and CLOSE limit switch's. Then relocate the safety limit switch (SLS) only to the opposite side with the new functional close limit location. Orient the arm (lever) of the limit switch away from the center. NOTE: The motor direction change is not available on the DJ and DH models. EXTERNAL RADIO WIRING CONNECTIONS On all models a radio terminal bracket marked R1 R2 R3 is located on the outside of the electrical enclosure. In B2 mode the operator will then open a fully closed door, close a fully open door, stop an opening door, and reverse a closing door from the radio remote. In TS control wiring the operator will only open the door or reset the timer to close. However, for additional door control from a 3-button remote, a commercial three-channel radio receiver (with connections for OPEN/CLOSE/STOP) is recommended. NOTE: If an external radio receiver is being used in place of the built-in receiver, remove or disconnect the coaxial cable from the logic board. MOUNTING INSTRUCTIONS 1. Mount WARNING NOTICE beside or below the control station. 2. Mount MAINTENANCE ALERT label to either side of control station. 3. Mount control station(s) within line of sight of door(s). WARNING To prevent possible SEVERE INJURY or DEATH, install reversing CAUTION sensors when: • The radio is used. • The 3-button control station is out of sight of the door. • Or ANY other control (automatic or manual) is used. Reversing devices are recommended for ALL installations. R31 U7 D8 C3Ø C18 P1Ø C17 C25 POWER D19 TIMER DEFEAT R8 D17 MAS D28 D31 D7 D6 D5 D4 24V AC 14 24V AC 13 TIMER DEFEAT 12 CMN 11 4 D23 EYES D15 EDGE OPEN D2Ø CLOSE D21 STOP D13 MAS 10 EYES 9 EDGE 8 OPEN 7 CLOSE 6 STOP 5 TS DIAG CMN 4 3 SBC ROG D1 E2) AILSAFE D14 P1 D34 2 SBC 1 F1 24V AC 14 24 VOLT AC 24V AC 13 24 VOLT AC TIMER DEFEAT 12 TIMER DEFEAT CMN 11 COMMON AVEMRASTI1S0 SMAEINMTENEANNCETALERT SYSTEM EYES 9 PHOTO EYES (LiftMaster Only) ATTEDGEE N8TRIEOVENRSE OPEN 7 OPEN CLOSE 6 CLOSE STOP 5 STOP CMN 4 COMMON 3 INTERLOCK 2 INTERLOCK SBC 1 SINGLE BUTTON CONTROL ADVERTENCIA PRECAUCIÓNOR IN THE AREA NEAR THE OPERATOR MUST NOT BE PERFORMED UNTIL DISCONNECTING THE ELECTRICAL POWER AND LOCKING-OUT THE POWER VIA, THE MAIN DISCONNECT SWITCH. UPON COMPLETION OF MAINTENANCE THE AREA MUST BE CLEARED AND SECURED, AT THAT TIME THE UNIT MAY BE RETURNED TO SERVICE. Control Station 4' Approximate Optional Controls Maintenance Alert SystemTM If light is Flashing Rapidly, it is time for routine door maintenance. If light is Flashing Slowly, followed by a pause, call for immediate service. 13 Service every cycles/months