Makita JN1601 Owners Manual - Page 7

Thickness gauge, Cutting line, Pre-lubrication, Cutting - punch

|

View all Makita JN1601 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 7 highlights

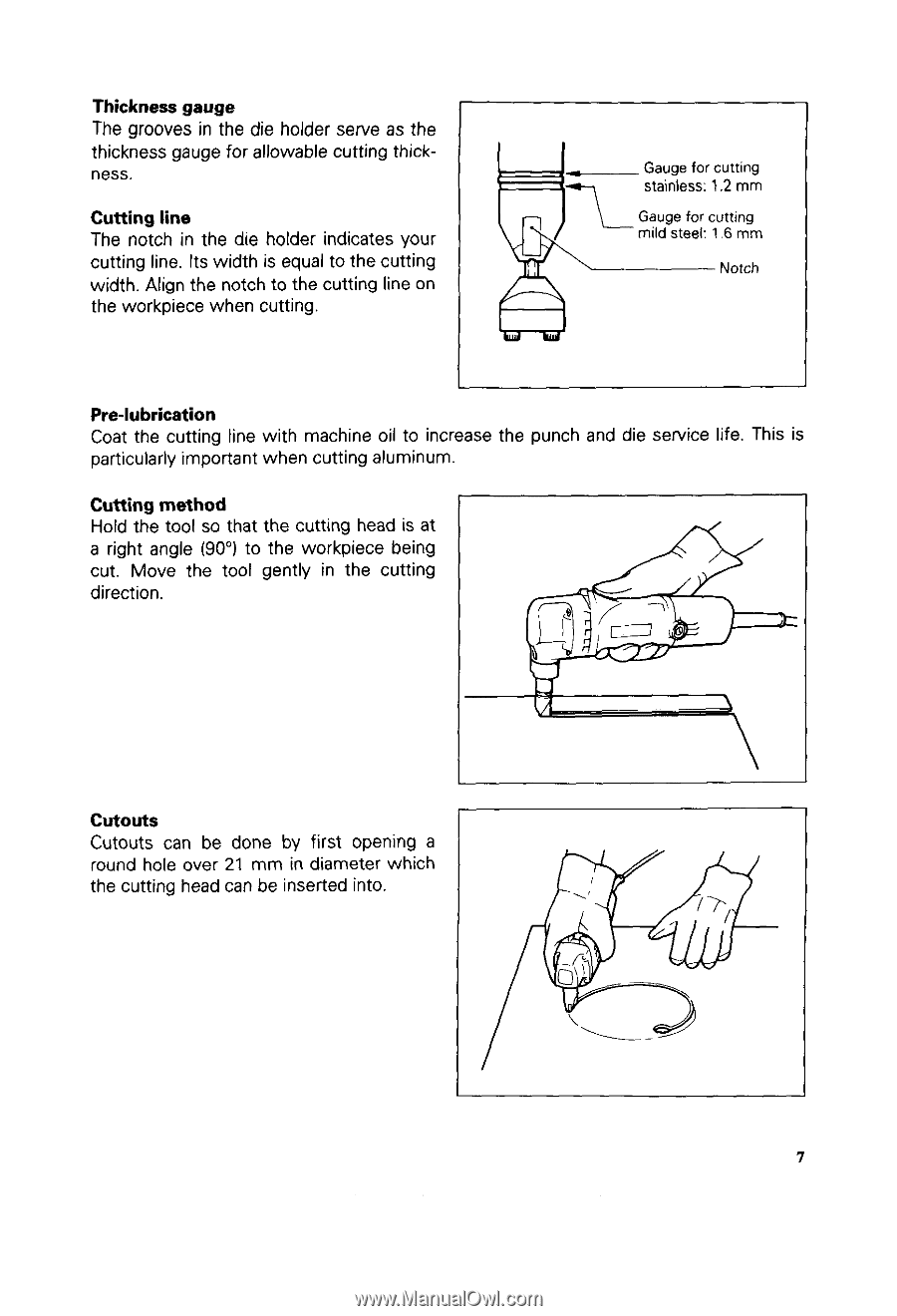

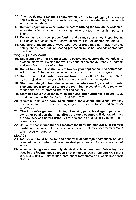

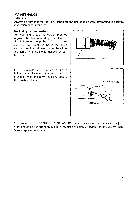

Thickness g-aug-e I The grooves in the die holder serve as the thickness gauge for allowable cutting thick- ness. Cutting line The notch in the die holder indicates your cutting line. Its width is equal to the cutting width. Align the notch to the cutting line on the workpiece when cutting. - Gauge for cutting stainless: 1.2 mm Gauge for cutting mild steel: 1.6 mm Notch Pre-lubrication Coat the cutting line with machine oil to increase the punch and die service life. This is particularly important when cutting aluminum Cutting method Hold the tool so that the cutting head is at a right angle (90") to the workpiece being cut. Move the tool gently in the cutting direction. cutouts Cutouts can be done by first opening a round hole over 21 mm in diameter which the cutting head can be inserted into. I 7