Makita JN3200 Owners Manual - Page 7

per pass; two passes should suf

|

View all Makita JN3200 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 7 highlights

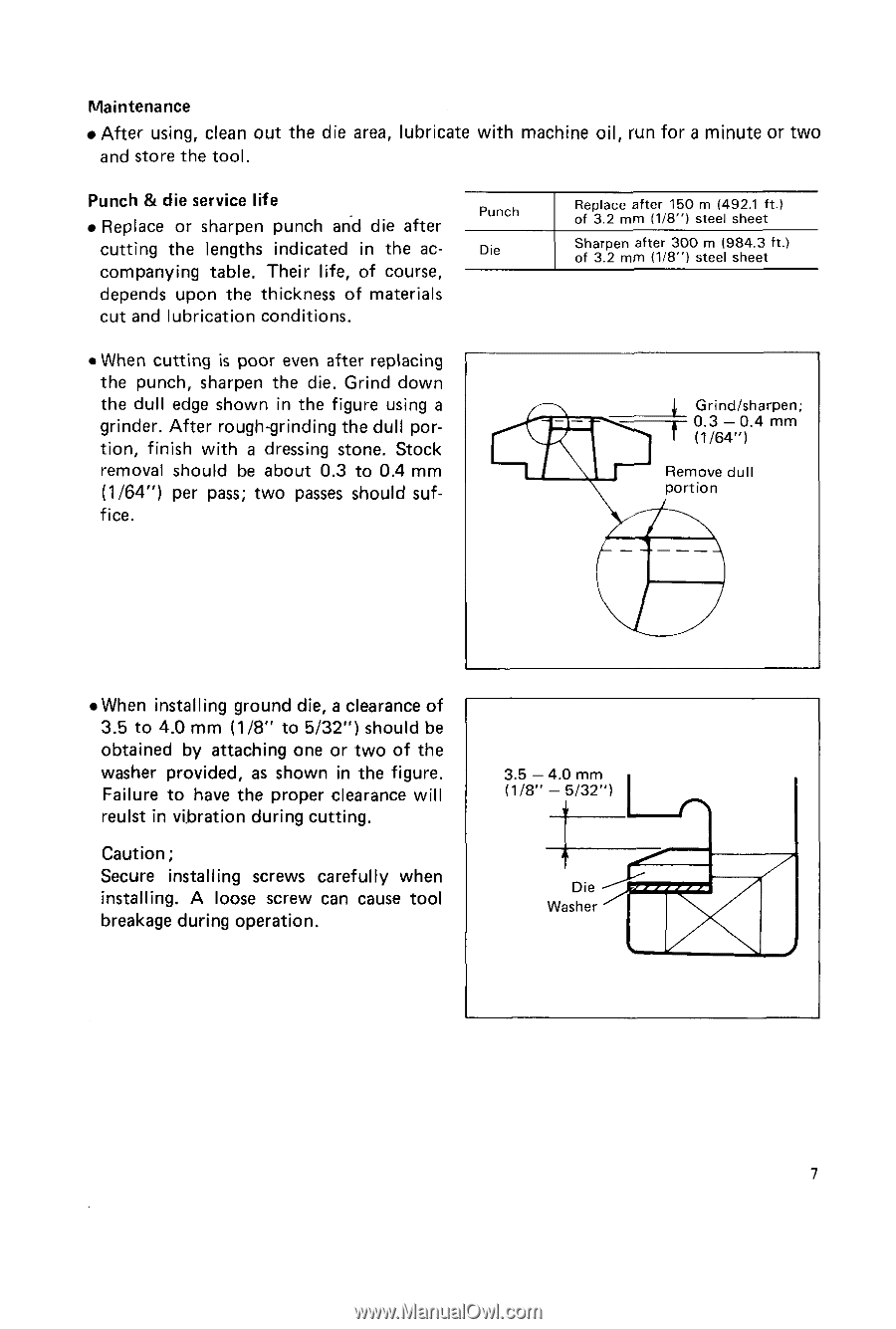

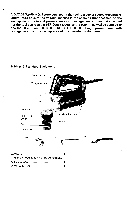

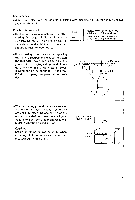

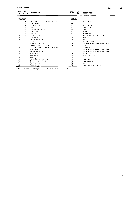

Maintenance After using, clean out the die area, lubricate with machine oil, run for a minute or two and store the tool. Punch & die service l i f e Replace or sharpen punch and die after cutting the lengths indicated in the accompanying table. Their life, of course, depends upon the thickness of materials cut and lubrication conditions. Punch Replace after 150 m (492.1 ft.) of 3.2 mm (118") steel sheet Sharpen after 3 0 0 m 1984.3 ft.) of 3.2 m m (118") steel sheet *When cutting is poor even after replacing the punch, sharpen the die. Grind down the dull edge shown in the figure using a grinder. After rough-grindingthe dull portion, finish with a dressing stone. Stock removal should be about 0.3 t o 0.4 mm (1/64") per pass; two passes should suffice. Grind/sharpen; Remove dull portion When installing ground die, a clearance of 3.5 t o 4.0 mm (1/8" to 5/32") should be obtained by attaching one or two of the washer provided, as shown in the figure. Failure t o have the proper clearance will reulst in vibration during cutting. Caution ; Secure installing screws carefully when installing. A loose screw can cause tool breakage during operation. rm 3.5-4.0mm I Washer