Makita JN3201 Owners Manual - Page 6

Maintenance - grinder

|

View all Makita JN3201 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 6 highlights

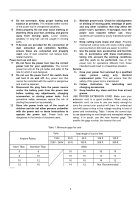

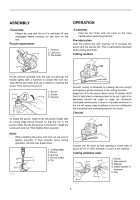

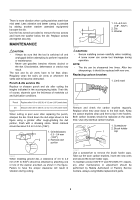

There is more vibration when cutting stainless steel than mild steel. Less vibration and better cutting is possible by adding another washer (standard equipment) beneath the die. Use the hex wrench provided to remove the two screws and insert the washer below the die. Replace screws and tighten securely. MAINTENANCE CAUTION: • Always be sure that the tool is switched off and unplugged before attempting to perform inspection or maintenance. • Never use gasoline, benzine, thinner, alcohol or the like. Discoloration, deformation or cracks may result. The tool and its air vents have to be kept clean. Regularly clean the tool's air vents or whenever the vents start to become obstructed. Punch & die service life Replace or sharpen punch and die after cutting the lengths indicated in the accompanying table. Their life, of course, depends upon the thickness of materials cut and lubrication conditions. Punch Replace after 150 m (492 ft.) of 3.2 mm (1/8") steel sheet Die Sharpen after 300 m (984 ft.) of 3.2 mm (1/8") steel sheet 006440 When cutting is poor even after replacing the punch, sharpen the die. Grind down the dull edge shown in the figure using a grinder. After rough-grinding the dull portion, finish with a dressing stone. Stock removal should be about 0.3 to 0.4 mm (1/64"). 1 2 1. Grind/sharpen; 0.3 - 0.4 mm (1/64") 2. Remove dull portion 004793 When installing ground die, a clearance of 3.5 to 4.0 mm (1/8" to 5/32") should be obtained by attaching one or two of the washer provided, as shown in the figure. Failure to have the proper clearance will result in vibration during cutting. 1. 3.5 -4.0 mm (1/8" - 5/32") 2. Die 1 3. Washer 2 3 004794 CAUTION: • Secure installing screws carefully when installing. A loose screw can cause tool breakage during operation. NOTE: • The die can be sharpened two times. After two sharpenings, it should be replaced with new one. Replacing carbon brushes 1. Limit mark 1 001145 Remove and check the carbon brushes regularly. Replace when they wear down to the limit mark. Keep the carbon brushes clean and free to slip in the holders. Both carbon brushes should be replaced at the same time. Use only identical carbon brushes. 1. Screwdriver 2. Brush holder 1 cap 2 013361 Use a screwdriver to remove the brush holder caps. Take out the worn carbon brushes, insert the new ones and secure the brush holder caps. To maintain product SAFETY and RELIABILITY, repairs, any other maintenance or adjustment should be performed by Makita Authorized or Factory Service Centers, always using Makita replacement parts. 6