Maytag MGD5500FC Instruction Sheet

Maytag MGD5500FC Manual

|

View all Maytag MGD5500FC manuals

Add to My Manuals

Save this manual to your list of manuals |

Maytag MGD5500FC manual content summary:

- Maytag MGD5500FC | Instruction Sheet - Page 1

feet (610 m), contact a qualified service agency for derating instructions. NOTE: A qualified service technician is any person or representative of a company who is experienced or trained in servicing gas equipment and is familiar with necessary precautions. Canada Only THIS CONVERSION KIT SHALL - Maytag MGD5500FC | Instruction Sheet - Page 2

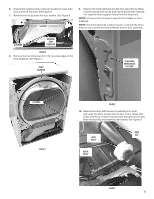

CABINET, FULL FRONT PANEL, AND REAR CONSOLE To gain access to inside of dryer: 1. Remove console rear plate and rear shelf plate by removing a total of the door switch connector located in the top left front corner of the dryer. See Figure 3. FRONT PANEL (4) SCREWS FIGURE 4 5. Disconnect the drum - Maytag MGD5500FC | Instruction Sheet - Page 3

right front corner of the dryer. See Figure 6. 7. Remove the two (2) lower lint duct screws. See Figure 6. LINT DUCT 9. Remove the front bulkhead and lint duct assembly by lifting it off the two (2) front hooks (see Figure 8) and then lowering it to clear the drum support rollers from the drum - Maytag MGD5500FC | Instruction Sheet - Page 4

10 12. Remove the front bulkhead and lint duct assembly by lifting it. Continue to "Determining Gas Valve Style" - "Changing the Orifice." (2) SCREWS FIGURE 1 2. Remove dryer top by sliding top toward rear of dryer and lift to remove. See Figure 2. FIGURE 2 3. Remove console by first removing two - Maytag MGD5500FC | Instruction Sheet - Page 5

cabinet left side panels, two (2) screws from right side panel and one (1) screw from central control bracket. Slightly lift assembly and remove from dryer. See Figures 10A and 10B. DOOR SWITCH CONNECTOR FIGURE 6 7. Remove front panel by first removing four (4) screws from bottom of front panel as - Maytag MGD5500FC | Instruction Sheet - Page 6

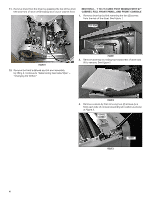

See Figure 12. (3) SCREWS - RIGHT SIDE CCU BRACKET MOISTURE SENSOR DISCONNECT BLOCK FIGURE 10B 11. Remove the bulkhead assembly from dryer by first removing lint screen from dryer lint duct. See Figure 11. LINT SCREEN MAIN HARNESS DISCONNECT BLOCK FIGURE 12 13. Remove lint duct by removing the - Maytag MGD5500FC | Instruction Sheet - Page 7

assembly the drum will need to be removed. Before removing drum from dryer the CCU and bracket assembly must be secured in position to side panel CLIPS - MAIN HARNESS CCU BRACKET FIGURE 16 17. Remove drum from dryer by first reaching into dryer just under the drum, to back side of drive motor. Grasp - Maytag MGD5500FC | Instruction Sheet - Page 8

and bracket assembly knocking it from its hanging position. Continue to "Determining Gas Valve Style" - "Changing the Orifice." 2. Remove two (2) hex WITH 29" CABINET, FULL FRONT PANEL, AND REAR CONSOLE 1. Lift dryer top. Use a putty knife to press against the left and right spring clips to release - Maytag MGD5500FC | Instruction Sheet - Page 9

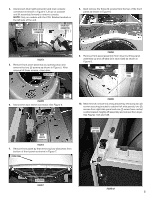

two (2) screws from the blower air duct. Gently remove the bulkhead and blower air duct from the front of the dryer. See Figure 5. (2) SCREWS BURNER TUBE GAS VALVE ASSEMBLY PRESSURE TAP PLUG FIGURE 1A IGNITOR BULKHEAD TOP TWO (2) SCREWS BOTTOM TWO (2) SCREWS LOWER TWO (2) SCREWS PRESSURE TAP - Maytag MGD5500FC | Instruction Sheet - Page 10

assembly. Securely tighten the two (2) mounting screws. See Figure 1A or 1B. 5. Before proceeding, you must first determine which gas valve style is on the dryer. Refer to Figure 4 - Style "A" and "B". PRESSURE REGULATOR REGULATOR VENT CAP STYLE "A" CAP - PERMANENTLY FIXED TO VALVE COVER DIAL - Maytag MGD5500FC | Instruction Sheet - Page 11

top of the burner data decal located on the burner baseplate. "LPG" SETTING PRESSURE TAP PLUG GAS VALVE ASSEMBLY (3/16") HEX WRENCH FIGURE 1 2. Insert pressure tap and finger-tighten. Remove view hole reconnect all wire leads and connections that were disconnected during disassembly of dryer. 11 - Maytag MGD5500FC | Instruction Sheet - Page 12

growing bubbles. See Figure 1. FIGURE 4 SIDE VIEW PRESSURE HOLE TAP PLUG 5. Plug in dryer or reconnect power. 6. Turn on gas supply. 7. Set dryer cycle to time dry, high heat and turn on dryer. 8. After ignition, verify gas inlet pressure is between 8" (203 mm) and 13" (330 mm) water column - Maytag MGD5500FC | Instruction Sheet - Page 13

par le personnel qualifié d'une agence de service/entretien, conformément aux instructions du fabricant et en conformité avec les consulter une agence de service/entretien qualifiée au sujet de la modification des données d'homologation que la conversion implique. Canada seulement L'INSTALLATION DE - Maytag MGD5500FC | Instruction Sheet - Page 14

à tête hexagonale de ¼ po. à l'avant en bas, trois (3) vis à empreinte cruciforme Phillips autour de l'ouverture de la porte et quatre (4) vis Torx T-20 sur le support supérieur du panneau de façade. Voir la Figure 4. Une fois les vis retirées, fermer la porte et lever l'ensemble panneau de fa - Maytag MGD5500FC | Instruction Sheet - Page 15

6. Débrancher le connecteur des bandes de détection d'humidité situées dans l'angle inférieur avant droit de la sécheuse. Voir la Figure 6. 7. Retirer les deux (2) vis inférieures du conduit à charpie. Voir la Figure 6. CONDUIT À CHARPIE 9. Retirer l'ensemble cloison avant et conduit à charpie en - Maytag MGD5500FC | Instruction Sheet - Page 16

11. Extraire le tambour de la sécheuse en prenant la courroie du tambour par le haut et l'avant du tambour, tout en faisant glisser le tambour hors de la caisse de l'appareil par l'avant. SECTION 2 : MODÈLES DE 7 À 7,5 PIEDS CUBES AVEC CAISSE DE 27 PO, PANNEAU DE FAÇADE PLEINE GRANDEUR ET CONSOLE - Maytag MGD5500FC | Instruction Sheet - Page 17

module de la console et faire basculer celui-ci vers l'avant pour la dépose. REMARQUE : Uniquement sur les modèles où le support du MCC est situé à gauche de l'appareil. SUPPORT DU MCC CONNECTEUR PRINCIPAL DE LA CONSOLE 8. Ôter ensuite les trois (3) vis de fixation au sommet du panneau de façade - Maytag MGD5500FC | Instruction Sheet - Page 18

REMARQUE : Uniquement sur les modèles où le support du MCC est situé à gauche de l'appareil. (3) VIS - CÔTÉ DROIT BRIDE DU MODULE DE COMMANDE CENTRAL 13. Ôter le conduit d'air chaud de la sécheuse : ôter d' - Maytag MGD5500FC | Instruction Sheet - Page 19

séparer le faisceau de câblage du module de la cloison. Voir la Figure 15. REMARQUE : Uniquement sur les modèles où le support du MCC est situé à droit de l'appareil. SUPPORT DU MCC MODULE DE LA CLOISON 16. Pour l'obtention d'un accès approprié au brûleur, il sera nécessaire d'enlever le tambour - Maytag MGD5500FC | Instruction Sheet - Page 20

18. Extraire le tambour de la sécheuse : saisir la courroie du tambour et l'avant du tambour, et faire glisser le tambour pour l'extraire par l'avant de la caisse. IMPORTANT : En prévision du remontage, noter la position de la courroie du tambour, et l'orientation à l'avant et à l'arrière. Voir la - Maytag MGD5500FC | Instruction Sheet - Page 21

5. Par l'arrière du moteur d'entraînement, pousser le bras de la poulie de tensionnement pour éliminer la tension du ressort sur la courroie; dégager la courroie de la poulie de tensionnement et de la poulie du moteur. Consulter la Figure 4. COURROIE Déterminer le type de l'électrovanne d'admission - Maytag MGD5500FC | Instruction Sheet - Page 22

3. Démonter le gicleur du brûleur de l'électrovanne d'admission de gaz, et installer à la place le gicleur approprié fourni dans cet ensemble. Le numéro du gicleur est gravé sur un pan de la tête hexagonale du gicleur. Veiller à bien serrer. Voir Figure 3. Utiliser le gicleur No 55 pour l' - Maytag MGD5500FC | Instruction Sheet - Page 23

ÈRE DE RÉGLAGE FIGURE 8 Installation - Liste de contrôle • Vérifier que les deux étiquettes ont été apposées/mises en place conformément aux instructions "Préparation pour l'installation de l'ensemble" - étape 3 et étape 10 ci-dessus. • Dans le cas de la conversion pour l'alimentation au propane - Maytag MGD5500FC | Instruction Sheet - Page 24

prise de pression d'une solution de détection des fuites homologuée (non corrosive). 2. Réinstaller les composants de la sécheuse - exécuter les instructions précédentes dans l'ordre inverse, comme décrit dans la section "Démontage de la sécheuse". 3. Ouvrir l'arrivée de gaz. 4. Brancher la sécheuse - Maytag MGD5500FC | Instruction Sheet - Page 25

9. Si on observe la formation de bulles, resserrer la connexion qui fait l'objet d'une fuite, et effectuer un nouveau test de recherche des fuites. REMARQUE : Si des bulles se forment sur le conduit d'arrivée de gaz, remplacer le conduit d'arrivée de gaz. 10. Si on n'observe pas la formation de - Maytag MGD5500FC | Instruction Sheet - Page 26

26 - Maytag MGD5500FC | Instruction Sheet - Page 27

27 - Maytag MGD5500FC | Instruction Sheet - Page 28

W10740674A ®/™ © 2014. All rights reserved. ®/™ © 2014. Tous droits réservés. 11/14 Printed in U.S.A. Imprimé aux É.-U.

W10740674A

Installation Instructions

for W10606694 L.P. (Propane and Butane)

Gas Conversion Kit

Parts included in Kit:

1 Instruction Sheet

1 Blocking Pin

1 Orifice, Burner-Butane No. .049

1 Orifice, Burner-Propane No. 55

1 Label, Rating Plate Conversion (English)

1 Label, Rating Plate Conversion (French)

1 Label, Conversion Record (English)

1 Label, Conversion Record (French)

1 Label, Burner Baseplate (English/French)

Converting 20,000 BTU/hr Gas Burners from Natural Gas

to Liquefied Petroleum (Bottled Gas)

NOTE:

A qualified service technician is any person or

representative of a company who is experienced or trained

in servicing gas equipment and is familiar with necessary

precautions.

IMPORTANT:

The LP Conversion Kit you received is an

approved kit for converting your gas dryer from natural to LP

propane or butane gas. The kit number shown on the Burner

Data Label located on the Burner Base may not match the kit

you receive due to kit consolidation.

NOTE:

Read these instructions before proceeding.

Canada Only

THIS CONVERSION KIT SHALL BE CARRIED OUT IN

ACCORDANCE WITH THE REQUIREMENTS OF THE

PROVINCIAL AUTHORITIES HAVING JURISDICTION AND

IN ACCORDANCE WITH THE REQUIREMENTS OF THE

CAN-B49.1 AND CAN1-B149.2 INSTALLATION CODE.

Warning:

This conversion kit shall be installed by a qualified

service agency in accordance with the manufacturer’s

instructions and all applicable codes and requirements of

the authority having jurisdiction. The information in these

instructions must be followed to minimize the risk of fire or

explosion or to prevent property damage, personal injury,

or death. The qualified service agency is responsible for the

proper installation of this kit. The installation is not proper

and complete until the operation of the converted appliance

is checked as specified in the manufacturer’s instructions

supplied with this kit.

This dryer has been manufactured for use with Natural Gas.

Installation of this conversion kit converts the dryer for use

with L.P. gas with supply pressure between 8" (203 mm) and

13" (330 mm) water column. If this dryer is converted for use

with L.P. gas by means of this kit, the input rating will be 20,000

BTU’s per hour, for altitudes up to 10,000 feet (3,048 m). For

installations above 2,000 feet (610 m), contact a qualified

service agency for derating instructions.

Preparing for Kit Installation

READ THOROUGHLY AND FOLLOW STEPS

1.

Unplug dryer or disconnect power.

2.

Turn off gas supply using the shut-off valve that supplies

the dryer.

3.

Fill out information on the appropriate Conversion Record

Label (English or French) and apply in a conspicuous

location adjacent to model and serial tag located in the

door well. Go to Section 1, 2, or 3, depending on model.

Tools and Accessories required:

1/4" Socket and Ratchet Wrench

1/4" Nut Driver

5/16" Nut Driver

Phillips-Head Screwdriver

T-20 Torx

®

-head Screwdriver

†

Pliers or Flat-Head Screwdriver

†® Torx and T-20 are registered trademarks of Acument Intellectual

Properties, LLC.

Disassembling the Dryer

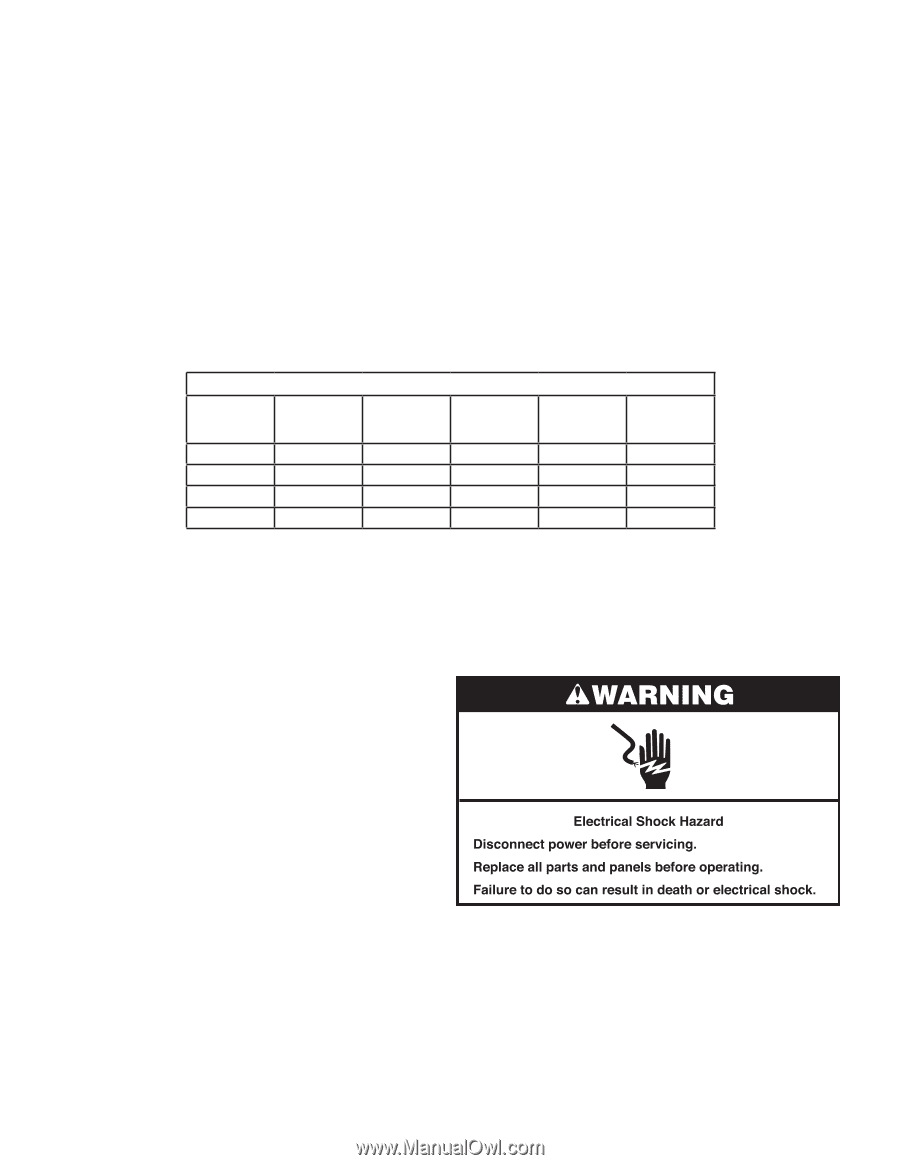

Section

Cabinet

Width

Console

Location

Front Panel

Type

Rated

Capacity

(cubic feet)

Page

1

29"

Rear

Full

8.8+

2

2

27"

Front

Full

7 to 7.5

4

3

29"

Rear

Full

7 to 7.6

8

4

27"

Rear

Toe Panel

7 to 7.5

9