Metabo KFM 9-3 RF Operating Instructions - Page 11

Original instructions - bevelling tool

|

View all Metabo KFM 9-3 RF manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 11 highlights

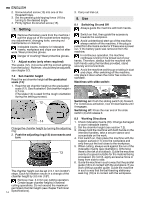

Original instructions ENGLISH en 1. Declaration of Conformity We, being solely responsible: Hereby declare that these bevelers, identified by type and serial number *1), meet all relevant requirements of directives *2) and standards *3). Technical documents for *4) see page 3. 2. Specified Use various operations. The dust mask or respirator must be capable of filtrating particles generated by your operation. Prolonged exposure to high intensity noise may cause hearing loss. d) Keep bystanders a safe distance away from work area. Anyone entering the work area must wear personal protective equipment. Fragments of workpiece or of a broken accessory may fly away and cause injury beyond immediate area of operation. The beveler is intended for the bevelling of edges of steel, stainless steel, aluminium and aluminium alloys in the professional sector. For processing aluminium, aluminium alloys and stainless steel, a suitable lubricant (item no.: 6.23443) must be used. The user bears sole responsibility for any damage caused by inappropriate use. e) Always hold the tool firmly in your hands during the start-up. The reaction torque of the motor, as it accelerates to full speed, can cause the tool to twist. f) Use clamps to support workpiece whenever practical. Never hold a small workpiece in one hand and the tool in the other hand while in use. Clamping a small workpiece allows you to use your hands to control the tool. Generally accepted accident prevention regulations and the enclosed safety information must be observed. 3. General Safety Instructions For your own protection and for the protection of your power tool, pay attention to all parts of the text that are marked with this symbol! WARNING - Reading the operating instructions will reduce the risk of injury. g) Never lay the power tool down until the accessory has come to a complete stop. The spinning accessory may grab the surface and pull the power tool out of your control. h) Do not run the power tool while carrying it at your side. Accidental contact with the spinning accessory could snag your clothing, pulling the accessory into your body. i) Regularly clean the power tool's air vents. The motor's fan will draw the dust inside the housing and excessive accumulation of powdered metal may cause electrical hazards. j) Do not operate the power tool near flammable WARNING Read all safety warnings and materials. Sparks and hot chips can ignite these instructions. Failure to follow all safety materials. warnings and instructions may result in electric shock, fire and/or serious injury. k) Do not use accessories that require liquid coolants. Using water or other liquid coolants may Keep all safety instructions and information for result in electrocution or shock. future reference. Pass on your power tool only together with these documents. 4.1 Kickback and Related Warnings Kickback is the sudden response to an accessory 4. Special Safety Instructions pinching or jamming while rotating. Pinching or snagging causes rapid stalling of the rotating accessory which in turn causes the uncontrolled a) Do not use accessories that are not specifically designed and recommended for power tool to be forced in the direction opposite of the accessory's rotation at the point of the binding. this power tool by the manufacturer. Just because the accessory can be attached to your power tool, it does not assure safe operation. For example, if an indexable insert is snagged or pinched by the workpiece, the edge of the insert that is entering into the pinch point can dig into the b) Do not use damaged power tools. Before surface of the material causing the insert to climb use, check the indexable inserts for chipping, out or kick out. The indexable insert may either jump cracks, or signs of severe wear and tear. If a toward or away from the operator, depending on power tool or accessory is dropped, inspect for direction of the indexable insert holder at the point damage or install an undamaged accessory. of pinching. Indexable inserts may also break under c) User personal protective equipment. Depending on application, use face shield, safety goggles or safety glasses. As appropriate, wear dust mask, hearing protectors, gloves and workshop apron these conditions. Kickback is the result of power tool misuse and/or incorrect operating procedures or conditions It can be prevented if suitable precautionary measures are taken as described below. capable of stopping small abrasive or workpiece fragments. The eye protection must be capable of stopping flying debris generated by a) Maintain a firm grip on the power tool and position your body and arm to allow you to 11