Pfaff hobbylock 783 Owner's Manual - Page 29

Incorrect

|

View all Pfaff hobbylock 783 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 29 highlights

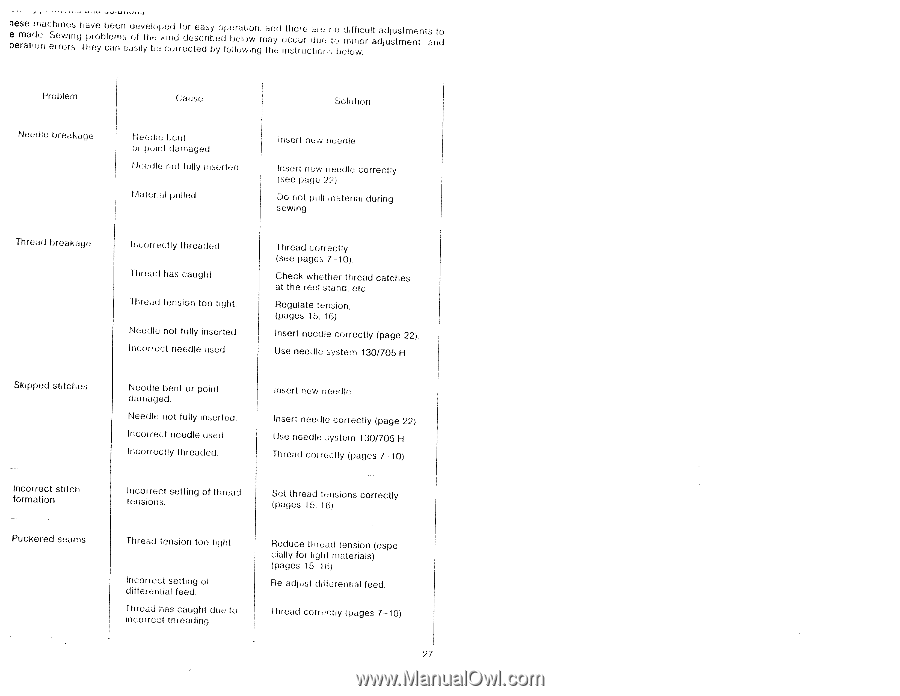

iese machines have been veliped for easy operation. and e made peratiori Sewing problems of ftc tind described below may errors Ihey can easily be corrected by follnwing the there etc ucr;ur (1(10 rnstruchoi tO difhcult adlustments fri 10 minOr adjust rnent and . below. Prohlerri Needle breakage Thread breakage Skipped stitches Incorrect stitch formation Puckered seams SO (01 it) fl F teedle bet it ni Intl damaged F lUL(Jk( riot fully ii iSe led Metered pulled Insert new i cedle Insert new needle correctly (see page 22) Do riot pull n aterial during sew i rig Ii icnr redly threaded 1 tread has caught 1 fired tension too fight. Needle not fully inserted Incur reef needle used Thread correctly (see pages 7-10) Check whether thread catches at the reel stamrd, etc. Regulate tension, (pages 15, 16) Insert needle correctly (page 22> use needle system 130/705 H Needle bent or pond damn aged Needle not fully inset led Incorrect needle used Incur redly threaded Insert new needle Insert needle correctly (page 221 Use needle system 130/705 H Thread cnr r ectly (pageS 7-10). Incorrect setting of thread tensto rs. Set thread tensions correctly (pages 15, 16) Thread tension too tight Incorrect setting of differential teed. 1 hreid has caught doe In incur reef threading Reduce thread tension (espe cially for light materials) (pages 15, 161 Re-adjust differential feed. Thread correctly pages 7- 10> 27