Poulan CHDR500C User Manual - Page 17

Remove, Guard, Replace, Ground, Drive, Figs., Adjustment

|

View all Poulan CHDR500C manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 17 highlights

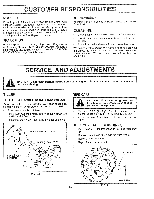

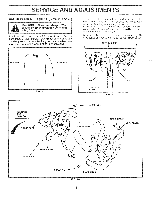

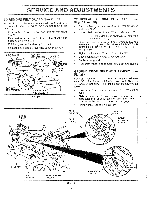

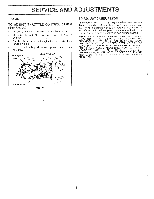

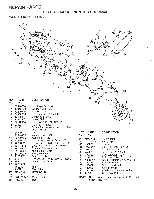

SERVICE AND ADJUSTMENTS TO REMOVE BELT GUARD (See Fig. 27) NOTE: For ease of removal, remove hairpin clip and clevis pin from left wheel. Pull wheel out from tiller about 1 inch (2.5 cm). • Remove two (2) cap nuts and washers from side of belt guard. • Remove hex nut and washer from bottom of belt guard (located behind wheel). • Pull belt guard out and away from unit. • Replace belt guard by reversing above procedure. BELT GUARD CAP NUT AND WASHER 0 HEX NUT AND WASHER (LOCATED BEHIND TIRE) CAP NUT AND WASHER 0 HAIRPIN CLIP AND CLEVIS PIN FIG. 27 TO REPLACE GROUND DRIVE BELT (See Figs. 27 and 28) • Remove belt guard as described in 'TO REMOVE BELT GUARD". • Loosen belt guides "A" and "B" and also stud "C". • Remove old belt by slipping off engine pulley first then remove transmission pulley. • Place new belt in groove of transmission pulley and into engine pulley. BELT MUST BE IN GROOVE ON TOP OF IDLER PULLEY. NOTE POSITION OF BELT TO GUIDES. • Tighten belt guides "A" and "B" and stud "C". • Check belt adjustment as described below. • Replace belt guard. • Reposition wheel and replace clevis pin and hairpin clip. GROUND DRIVE BELT ADJUSTMENT (See Fig. 25) For proper belt tension, the extension spring should have about 5/8 inch (16 mm) stretch when drive control bar is in "ENGAGED" position. This tension can be attained as follows: • Loosen cable clip screw securing the drive control cable. • Slide cable forward for less tension and rearward for more tension until about 5/8 inch (16 mm) stretch is obtained while the drive control bar is engaged. • Tighten cable clip screw securely. ENGINE PULLEY 4-- 1 BELT GUIDE "A" BELT • GUIDE "B" CABLE CLIP SCREW DRIVE CONTROL CABLE SAff t)b) STUD "C" IDLER PULLEY TRANSMISSION PULLEY FIG. 28 17 LESS TENSION 6-, EXTENSION SPRING 5/8" MORE TENSION