RedMax HEZ2460F Owners Manual - Page 15

Replacement Plug Is A Ngk, Drive Shaft Ma6

|

View all RedMax HEZ2460F manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 15 highlights

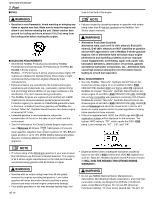

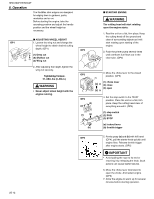

9. Maintenance MA1 (1) MA2 WARNING • Make sure that the engine has stopped and is cool before performing any service to the machine. Contact with moving cutting head or hot muffler may result in a personal injury. ■ AIR FILTER • The air filter, if clogged, will reduce the engine performance. Check and clean the filter element. If the element is broken or clogged, replace with a new one. (MA1) (1) air filter ■ FUEL FILTER • When the engine runs short of fuel supply, check the fuel cap and the fuel filter for blockage. (MA2) (1) fuel filter MA4 (1) MA3 .026 in 0.65 mm ■ SPARK PLUG • Starting failure and mis-firing are often caused by a fouled spark plug. Clean the spark plug and check that the plug gap is in the correct range. For a replacement plug, use the correct type specified by RedMax. (MA3) • REPLACEMENT PLUG IS A NGK CMR7H. MA5 IMPORTANT • Note that using any spark plug other than those designated may result in the engine failing to operate properly or in the engine becoming overheated and damaged. • To install the spark plug, first turn the plug until it is finger tight, then tighten it a quarter turn more with a socket wrench. TIGHTENING TORQUE: 87~104 in-lbs (9.8~11.8 N.m.) MA6 HEZ2460F/HEZ2650F ■ MUFFLER WARNING • Inspect periodically, the muffler for loose fasteners, any damage or U S corrosion. If any sign of exhaust leakage is found, stop using the machine and have it repaired immediately. • Note that failing to do so may result in the engine catching on fire. ■ SPARK ARRESTER • The muffler is equipped with a spark arrester to prevent red hot carbon from flying out of the exhaust outlet. Periodically inspect and clean as necessary with a wire brush. In the State of California it is required by law (Section 4442 of the California Public Resources Code) to equip a spark arrester when a gas powered tool is used in any forest covered, brush covered, or grass covered unimproved (1) land. (MA4) (1) spark arrester ■ GEAR CASE • The reduction gears are lubricated by multipurpose, lithium-based grease in the gear case. At every 25 hours of use, supply the gear case with new grease. (MA5) • Remove the cutter holders before installing new grease to arrange for old grease to exit. (MA7) NOTE • When removing and installing the holder(A), use care not to allow any dirt and dust entering in to the gear case. (MA7) ■ DRIVE SHAFT (MA6) • The drive shaft is lubricated by multipurpose lithium-based grease (NLGI No.2). Pull out the shaft from the pipe and supply new grease every 50 hours of use or more often depending on the job condition. US-15