Ryobi RY34005 User Manual - Page 12

Maintenance

|

View all Ryobi RY34005 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 12 highlights

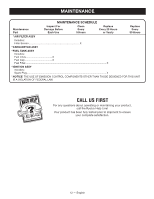

MAINTENANCE WARNING: Do not at any time let brake fluids, gasoline, petroleumbased products, penetrating lubricants, etc., come in contact with plastic parts. Chemicals can damage, weaken or destroy plastic which can result in serious personal injury. You can often make adjustments and repairs described here. For other repairs, have the power head serviced by an authorized service dealer. IDLE SPEED ADJUSTMENT See Figure 9. WARNING: The blade/cutting head will move when adjusting the idle speed. Wear all protective clothing and keep all bystanders, children, and pets at least 50 ft. away. Make adjustments with the unit supported by hand so that the blade/cutting head does not contact the ground or any object. Keep all parts of your body away from the blade/ cutting head and muffler. Failure to follow these instructions could result in serious personal injury. If the cutting attachment turns at idle, the idle speed screw needs adjusting on the engine. Turn the idle speed screw counterclockwise to reduce the idle RPM and stop the cutting attachment movement. If the cutting attachment still moves at idle speed, contact a service dealer for adjustment and discontinue use until the repair is made. WARNING: The cutting attachment should never turn at idle. Turn the idle speed screw counterclockwise to reduce the idle RPM and stop the cutting attachment, or contact a service dealer for adjustment and discontinue use until the repair is made. Serious personal injury can result from the cutting attachment turning at idle. CLEANING AIR FILTER SCREEN See Figures 10 - 11. For proper performance and long life, keep air filter screen clean. Remove the air filter cover by pushing down on the latch with your thumb while gently pulling on the cover. Brush the air filter screen lightly to clean. Replace the air filter cover by inserting the tabs on the bottom of the cover into the slots on the air filter base; push the cover up until it latches securely in place. FUEL CAP, TANK, AND LINES WARNING: Check for fuel leaks. A leaking fuel cap, tank, or lines are a fire hazard and must be replaced immediately. If you find any leaks, correct the problem before using the product. Failure to do so could result in a fire that could cause serious personal injury. The fuel cap contains a non-serviceable filter and a check valve. A clogged fuel filter will cause poor engine performance. If performance improves when the fuel cap is loosened, check valve may be faulty or filter clogged. Replace fuel cap if required. SPARK PLUG REPLACEMENT This engine uses a Champion RY4C or equivalent spark plug with .025 in. electrode gap. Use an exact replacement and replace annually. NOTICE: Be careful not to cross-thread the spark plug. Crossthreading will seriously damage the product. CHANGING ENGINE LUBRICANT See Figure 12. For best performance, engine lubricant should be changed after every 25 hours of operation. To change the engine lubricant: Stop the engine and disconnect the spark plug wire. Allow the engine to cool completely before proceeding. Remove the screw from the top engine cover and set aside. Remove the screws from the bottom of the engine cover. Remove the bottom cover and set aside. Remove the oil fill cap/dipstick. Tip power head on its side and allow lubricant to drain from the oil fill hole into an approved container. NOTE: Drain the lubricant while the engine is still warm but not hot. Warm lubricant will drain quickly and more completely. Return the power head to an upright position and refill with lubricant following the instructions in the Adding/ Checking Engine Lubricant section previously in this manual. Reinstall the bottom engine cover. Replace the screws and tighten securely. 10 - English