Sanyo VR-L4110WSEC Booklet - Page 15

Anti-Contamination Measures, Horizontal Laminar, Airflow System, Optional UV Sterilization,

|

View all Sanyo VR-L4110WSEC manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 15 highlights

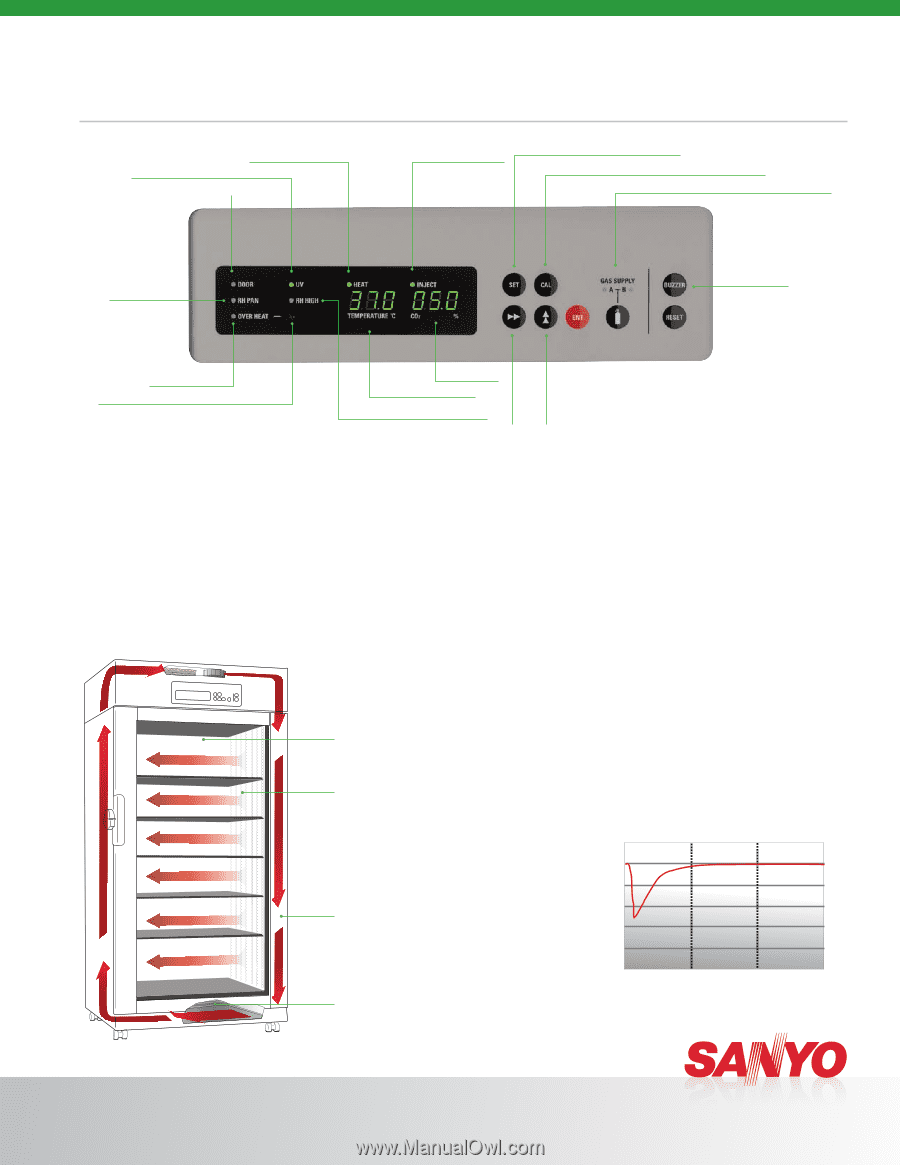

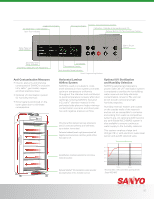

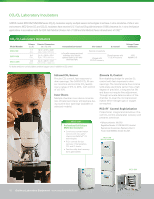

Heater On Indicator UV Sterilization - Light Indicator Open Door Indicator CO2 Inject Indicator Setpoint - Set Temperature and CO2 Calibration - Calibrate air temperature and CO2 Optional Built-in CO2 Tank Switchover System Water Reservoir Level Indicator Alarm, Buzzer Silence Secondary Over Temp. Indicator Over Temp. Safety Shut off Adjustment Anti-Contamination Measures • Interior, plenums and shelving constructed of SANYO's exclusive inCu saFe™, germicidal, copperenriched stainless steel. • Optional UV sterilization system for humidity reservoir. • Extra heaters positioned on the outer glass door to eliminate condensation. CO2 Display Temperature Display High Humidity Mode Indicator Scroll Programming Buttons Horizontal Laminar Airflow System SANYO's reach-in incubator's crossshelf directed air flow system promotes optimum temperature uniformity throughout the chamber and contributes to quick temperature recovery after door openings. Utilizing SANYO's exclusive inCu saFe™ chamber material in the perforated side plenums helps minimize contamination concerns and direct positive and negative pressure air flow. Horizontal airflow maintains accurate temperature and CO2 control and uniformity at all shelf levels, top-to-bottom, front-to-back. Perforated sidewall panels right (pressure) and left (negative pressure) assure a positive, gentle airflow from right to left. Optional UV Sterilization and Humidity Selection SANYO's patented and laboratory proven Safe Cell UV™ sterilization system is employed to sterilize the humidifying water reservoir and help eliminate contamination concerns. The unit can be set to both nominal and high humidity setpoints. Humidity reservoir heaters are located on tChOe2 roecuotvseirdyeaftweraal6ls0 soefcotnhdedoreorsoeprevnoinigr and are notfoarsthseuSsAcNeYOptMibClOe-8t0oICcorrosion and scaling from water as competitive 5% systems are. An optional autofill seconda4r%y tank (Model MCO-80AS) system is a3l%so available to ensure continuous water supply to the humidity reservoir. 2% T1h%is system employs a large tank (4.8 gal./18 L), with electronic water level sensor and a1u0tmoinf.ill solen2o0 imdin.valve. Temperature Recovery 37°C 36°C Humidified air minimizes potential for cell culture 35°C media desiccation. 34°C 33°C Optional SafeCell™ UV sterilization system provides decontamination of the humidity reservoir. 10 min. 20 min. Recovery after a 30 second door opening for the Sanyo MCO-80IC. CO2 recovery after a 60 second door opening for the competitor 5% 4% 3% 15 2% 1%